Preparation method of catalyst for synthesizing 1-octylene through selective oligomerization of ethylene

A selective, catalyst technology, applied in the direction of carbon compound catalysts, catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Problems such as increased wax content, to achieve the effect of simplifying the product post-processing process, high selectivity, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a catalyst for ethylene selective oligomerization into 1-octene, comprising:

[0041] A) synthesis of molecular sieves containing amino groups;

[0042] B) mixing the amino-containing molecular sieve, solvent, acid-binding agent, and diphenylphosphine chloride, stirring for reaction, filtering, and recrystallization to obtain the PNP ligand;

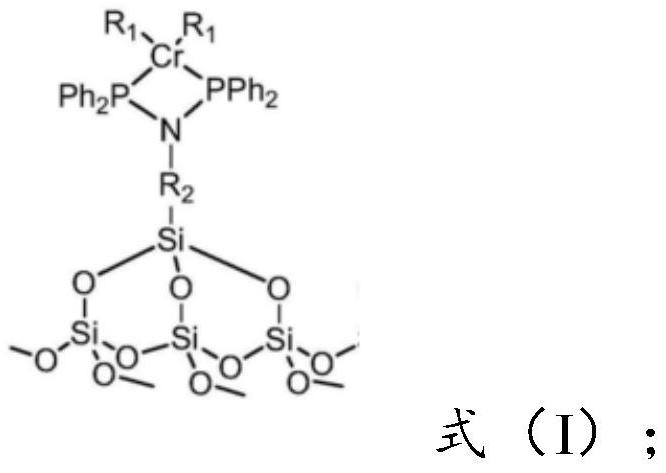

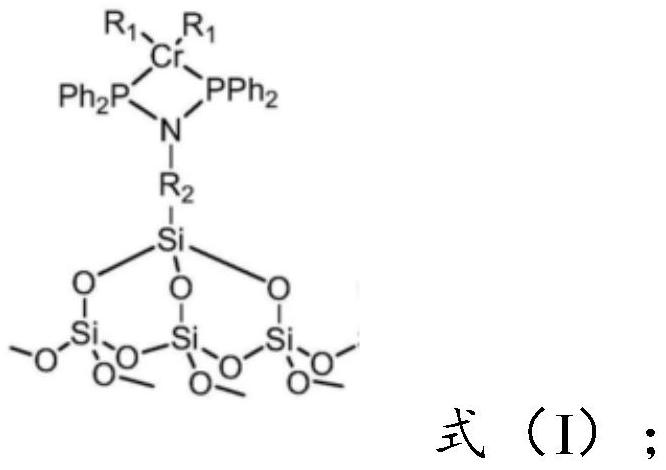

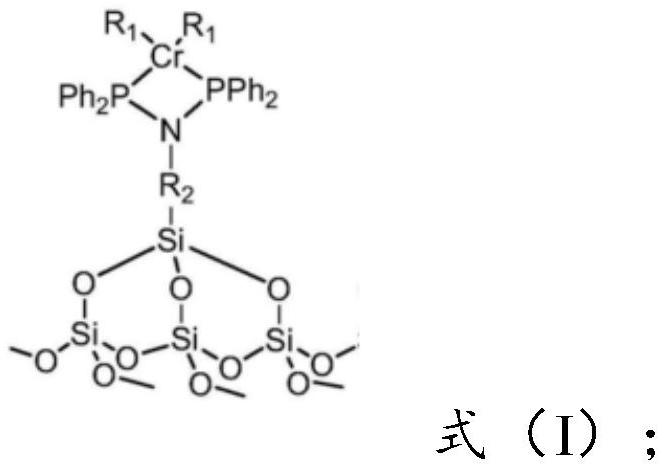

[0043] C) mixing the PNP ligand with a chromium source and a solvent, heating for reaction, filtering, washing, and drying to obtain a supported heterogeneous catalyst with a structure of formula (I);

[0044]

[0045] Among them, R 1 is chlorine; R 2 is ethyl, isopropyl, butyl, cyclohexyl or phenyl.

[0046] The invention provides a method for preparing a catalyst for selective oligomerization of ethylene to synthesize 1-octene. Firstly, molecular sieves containing amino groups are synthesized.

[0047] According to the present invention, the specific method for the synthesis o...

Embodiment 1

[0098] (1) Synthesis of molecular sieves containing amino groups: Weigh 0.6g of cetyltrimethylammonium bromide (CTAB), dissolve it in 40g of deionized water, stir it at 27°C to completely dissolve it, and then add it to the solution Add 3ml of ammonia water, and continue to stir for 30min; then add 10ml of ethanol solution containing 3g of tetraethyl orthosilicate (TEOS) and 0.5g of organic silicon containing amino groups, and continue to stir at 27°C for 24h. Heat the obtained solution to 85°C or transfer it to a PTFE-lined 100ml crystallization kettle and treat it at 85°C for 24 hours, then perform suction filtration, rinse with deionized water, and dry at 60°C to obtain the product Extract with ethanol at 75°C for 3 to 5 times to remove the template agent, and obtain MCM-41 molecular sieves containing amino groups.

[0099] (2) Synthesis of PNP ligand: Take 6.8ml of amino-containing molecular sieves and 28.7ml of triethylamine in a nitrogen-protected reaction flask, add 152...

Embodiment 2

[0102] (1) Synthesis of molecular sieves containing amino groups: Weigh 2.0g block copolymer EO20PO70EO20 (P123), dissolve it in 40g deionized water, stir at 40°C to make it completely dissolve, then add 3ml HCl (37%) to the solution , continue to stir for 30 min, then add 10 ml of ethanol solution containing 4 g of tetraethyl orthosilicate (TEOS) and 1 g of amino group-containing organosilicon, and continue to stir rapidly at 40° C. for 24 h. Heat the obtained solution to 85°C or transfer it to a polytetrafluoroethylene-lined 100ml crystallization kettle and treat it at 85°C for 24 hours, then perform suction filtration, rinse with deionized water, and dry at 60°C. The obtained product is washed with ethanol Extract at 75°C for 3 to 5 times to remove the template agent, and obtain SBA-15 molecular sieves containing amino groups.

[0103] (2) Synthesis of PNP ligand: Take 6.8ml of amino-containing molecular sieves and 28.7ml of triethylamine in a nitrogen-protected reaction fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com