Electrochemical conductive oxidizing technology method of aluminum and aluminum alloy

A technology of conductive oxidation and process method, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of high cost of chromium-free conversion treatment technology, high solution stability, difficult on-line detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

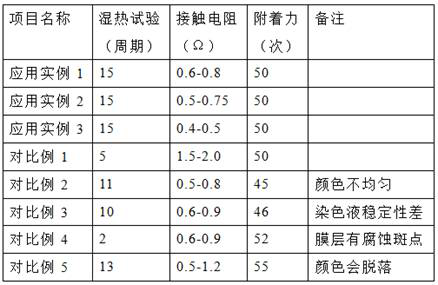

Examples

Embodiment 1

[0041]Aluminum and aluminum alloy electrochemical conductive oxidation process, including the following steps:

[0042]Step 1: Organic solvent removal treatment: EtOAc EtOAc EtOAc EtOAc EtOAc.

[0043]Step 2: Chemical removal treatment: Work members after steps are placed in an aluminum substrate deinterlet-free, and then rinse the surface skim of the surface of 40 ° C, then rinse with flow tap water;

[0044]Step 3: Alkali EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc Solidizing Sodium oxide and sodium carbonate, sodium hydroxide content are 40 g / L, sodium carbonate is 5g / L

[0045]Step 4: Outlet Treatment: The workpiece treated step three is placed at room temperature for 2 min; then flush with flow tap water, then rinse with flow deionized water; the light-liquid solution contains nitric acid, the nitric acid content is 400g / L;

[0046]Step 5: Electrolysis processing: The workpiece processed by step four is placed in the electrolytic tank, the t...

Embodiment 2

[0059]Aluminum and aluminum alloy electrochemical conductive oxidation process, including the following steps:

[0060]Step 1: Organic solvent removal treatment: EtOAc EtOAc EtOAc EtOAc EtOAc.

[0061]Step 2: Chemical removal treatment: Work members after steps are placed in an aluminum substrate deinterlet-free, and then rinse the surface skim of the surface of 40 ° C, then rinse with flow tap water;

[0062]Step 3: Alkali EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc Solidizing Sodium oxide and sodium carbonate, sodium hydroxide content are 40 g / L, sodium carbonate is 5g / L

[0063]Step 4: Outlet Treatment: The workpiece treated step-processed workpiece is placed at room temperature for 1min; then rinse with flow tap water, then rinse with flow deionized water; the lighting solution contains nitric acid, nitric acid content of 400g / L;

[0064]Step 5: Electrolysis processing: The workpiece processed by step four is placed in the electrolytic tank, the ta...

Embodiment 3

[0077]Aluminum and aluminum alloy electrochemical conductive oxidation process, including the following steps:

[0078]Step 1: Organic solvent removal treatment: EtOAc EtOAc EtOAc EtOAc EtOAc.

[0079]Step 2: Chemical removal treatment: Working members after steps are placed in an aluminum substrate deinterlete, and then rinse the surface degreaser with a hot water of 80 ° C after absorbing, and then rinsed with flowing tap water;

[0080]Step 3: Alkali EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc Solidizing Sodium oxide and sodium carbonate, sodium hydroxide content of 60 g / L, sodium carbonate is 10 g / L;

[0081]Step 4: Outlet Treatment: The workpiece processed by step three is placed at room temperature for 3 min; then flush with flow tap water, then rinse with flow deionized water; the light-suction solution contains nitric acid, the nitric acid content is 600g / L;

[0082]Step 5: Electrolysis processing: The workpiece processed by step four is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com