Perovskite solar cell electron transport layer and production method thereof

A technology of electron transport layer and solar cell, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as the decline in the stability of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

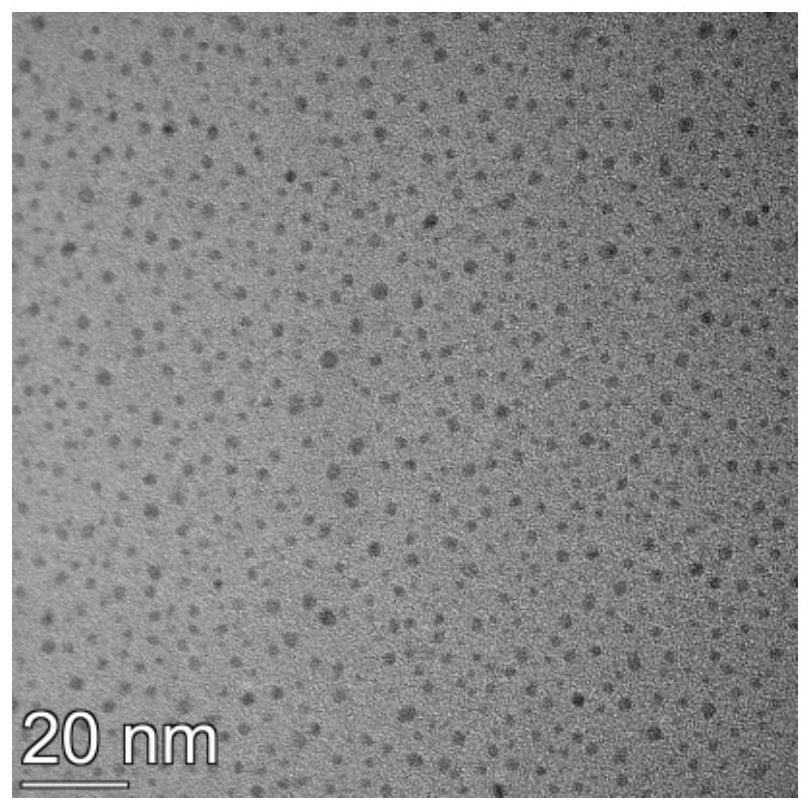

Image

Examples

preparation example Construction

[0022] A preparation method for an electron transport layer of a perovskite solar cell, comprising the following steps:

[0023] Step 1, the two-dimensional thin layer Ti with a concentration of 10wt% to 50wt% 3 C 2 The aqueous dispersion is placed in a planetary ball mill and ball milled for 4 to 8 hours at a speed of 7000 to 8000 rpm to make a two-dimensional thin layer of Ti 3 C 2 Two-dimensional thin-layer Ti in aqueous dispersion 3 C 2 Crushed into a size of 0.1 ~ 0.5μm 2 Ti 3 C 2 debris;

[0024] Step 2, then will contain Ti after ball milling 3 C 2 Fragmented 2D Ti 3 C 2 The water dispersion is added to 1-2mol / L alkaline solution to obtain a mixed suspension, and stirred for 120-144 hours in an oxygen atmosphere at a speed of 7000-8000 rpm to make the Ti in the mixed suspension 3 C 2 Fragments are oxidized and decomposed into rutile phase titanium dioxide fragments;

[0025] Step 3, then ultrasonicating the mixed suspension obtained in step 2 at a power of...

Embodiment 1

[0032] A preparation method for an electron transport layer of a perovskite solar cell, comprising the following steps:

[0033] Step 1, first prepare 100mL of two-dimensional monolayer Ti with a concentration of 10wt% 3 C 2 The aqueous dispersion was placed in a planetary ball mill and ball milled for 4 hours at a speed of 8000 rpm to make a two-dimensional monolayer Ti 3 C 2 Two-dimensional monolayer Ti in aqueous dispersion 3 C 2 Crushed into a size of 0.1 ~ 0.2μm 2 Ti 3 C 2 debris;

[0034] Step 2, then the two-dimensional monolayer Ti after ball milling3 C 2 The aqueous dispersion of fragments was added to 400mL, 2mol / L ammonia water to obtain a mixed suspension, and stirred for 120 hours at a speed of 8000 rpm in an oxygen atmosphere to make the Ti in the mixed suspension 3 C 2 Fragments are oxidized and decomposed into rutile phase titanium dioxide fragments;

[0035] Step 3, then the mixed suspension obtained in step 2 is ultrasonicated at a power of 1000W f...

Embodiment 2

[0043] A preparation method for an electron transport layer of a perovskite solar cell, comprising the following steps:

[0044] Step 1, first 100mL, the two-dimensional thin layer (2~5 layers) Ti that concentration is 50wt% 3 C 2 The aqueous dispersion was placed in a planetary ball mill and ball milled at a speed of 7000 rpm for 8 hours to make the two-dimensional thin layer Ti 3 C 2 Two-dimensional thin-layer Ti in aqueous dispersion 3 C 2 Crushed into a size of 0.3 ~ 0.5μm 2 Ti 3 C 2 debris;

[0045] Step 2, then ball milled containing Ti 3 C 2 Fragmented 2D Ti 3 C 2 The aqueous dispersion was added to 100mL, 2mol / L tetrabutylammonium hydroxide solution to obtain a mixed suspension, and stirred for 144 hours at a speed of 7000 rpm in an oxygen atmosphere to make the Ti in the mixed suspension 3 C 2 Fragments are oxidized and decomposed into rutile phase titanium dioxide fragments;

[0046] Step 3, then ultrasonicating the mixed suspension obtained in step 2 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com