Composite magnetorheological fluid

A magnetorheological fluid and composite technology, applied in the direction of magnetic fluid, can solve the problems of instability in the second Newton zone, affecting the high shear rate flow performance of magnetorheological fluid, and high environmental protection requirements, so as to improve the anti-settling performance , low initial kinematic viscosity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

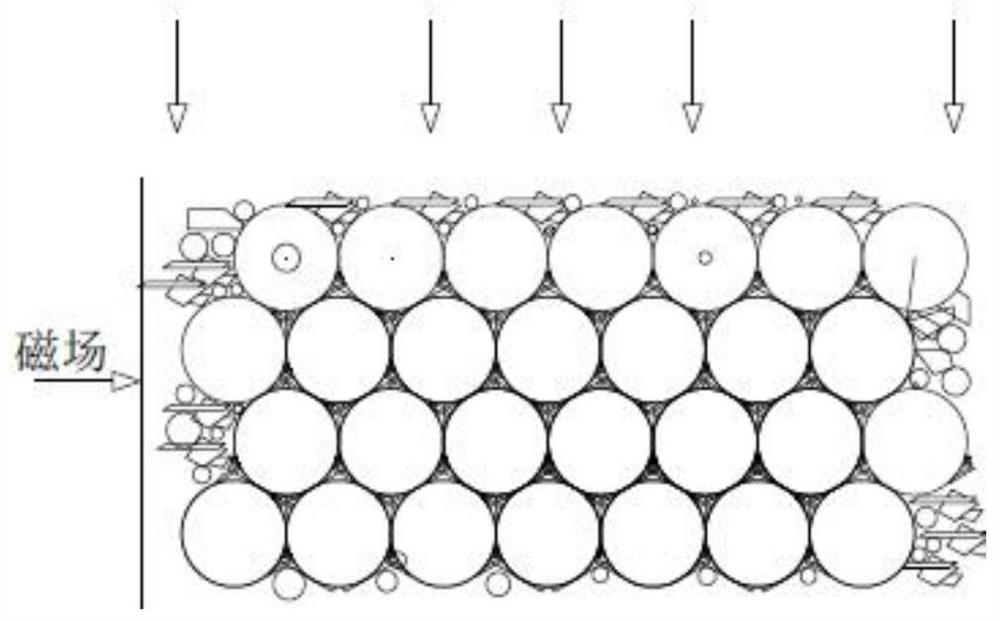

Image

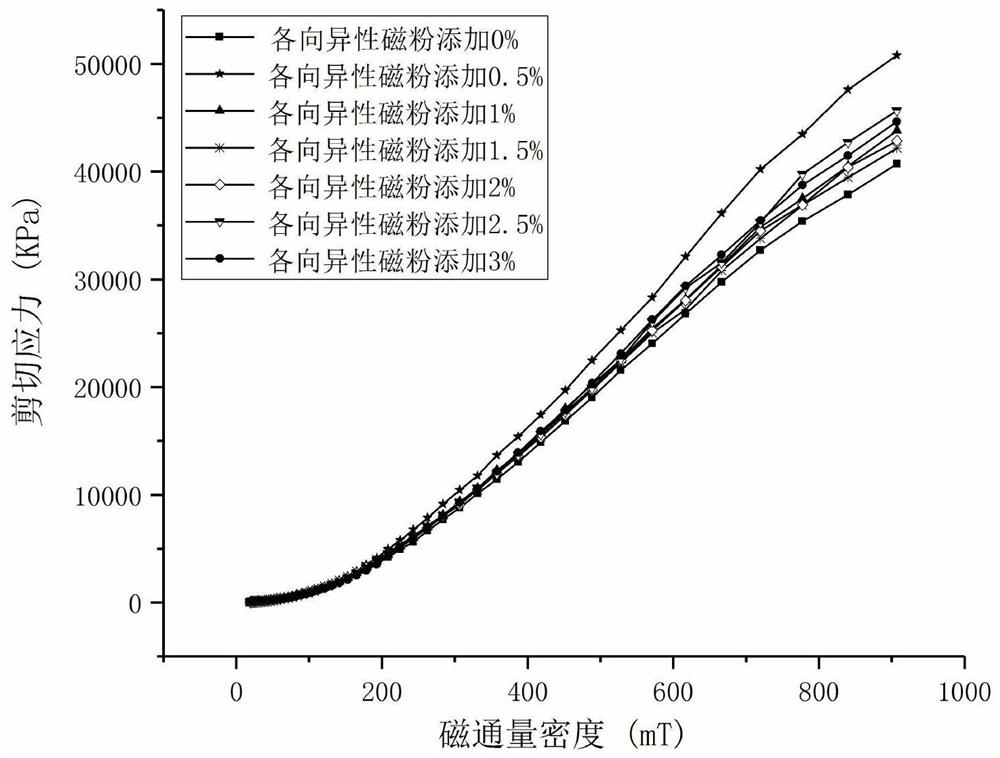

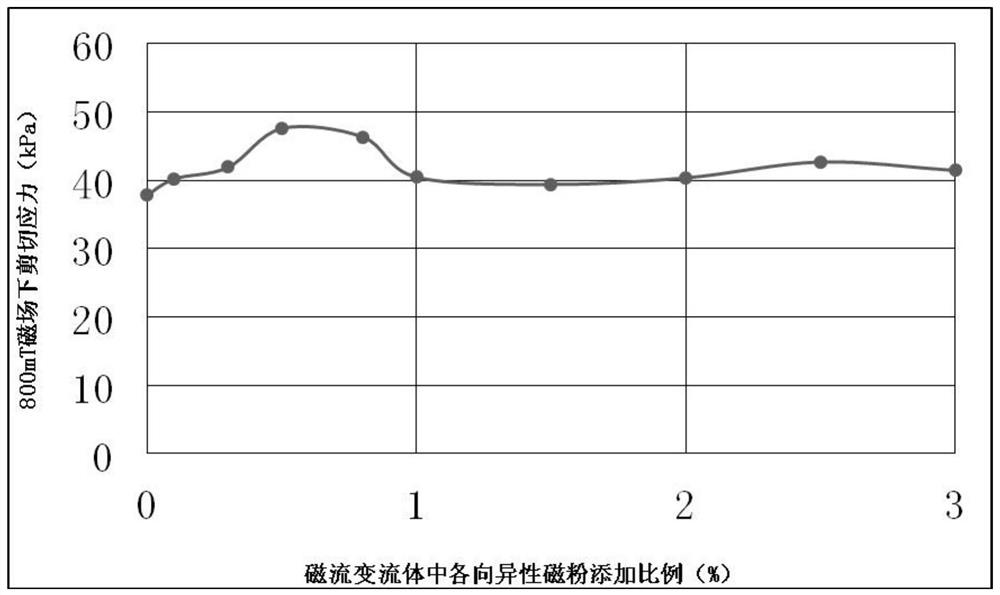

Examples

example I

[0051] Prepare the carrier fluid of the composite magnetorheological fluid, which can use mineral oil, synthetic oil, α-olefin or silicone oil, etc., which can be purchased from the market.

[0052] Additives for preparing the composite magnetorheological fluid, optional additives include but not limited to organoclay, molybdenum disulfide, fumed silica, etc., all of which can be purchased from the market.

[0053] The steps of a preparation process of composite magnetorheological fluid are as follows.

[0054] Step 1. Disperse the additives

[0055] The process that can be adopted in this step can be selected from a kind of in following:

[0056] 1. Add organoclay and fumed silica at room temperature into a container of an ultrasonic mixer (for example, model JM-1018), and perform ultrasonic stirring and dispersion treatment for about 20 minutes at a stirring frequency of about 30 Hz;

[0057] 2. Add organoclay and fumed silica at room temperature to a circulating sand mi...

example II

[0071] The preparation process, steps, equipment, raw materials, components, parameters, etc. of this example and Example I are basically the same, the difference is that the anisotropic magnetic powder adopts single crystal anisotropic magnetic powder, and the added single crystal isotropic The heterosexual magnetic powder accounts for 2% of the total weight of the magnetorheological fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com