Method for continuously preparing 3, 5-dinitrobenzoic acid by using micro-channel reactor

A technology of dinitrobenzoic acid and microchannel reactor, which is applied in chemical instruments and methods, preparation of nitro compounds, chemical/physics/physicochemical processes, etc. "Warm" risk, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

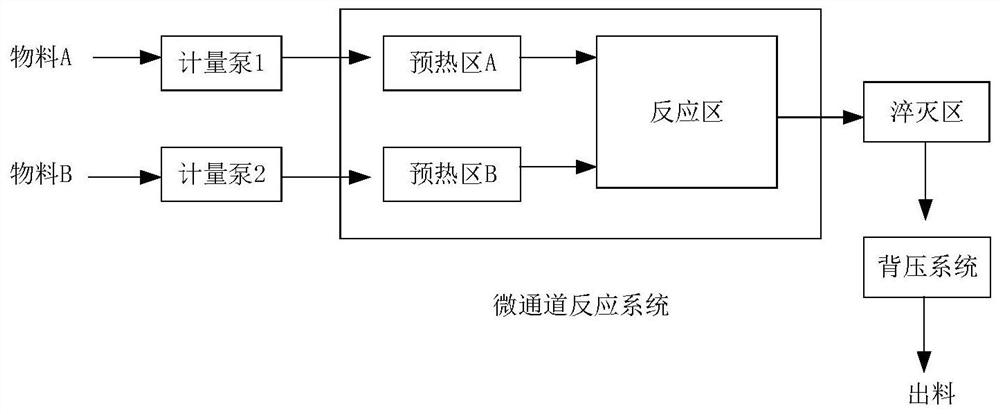

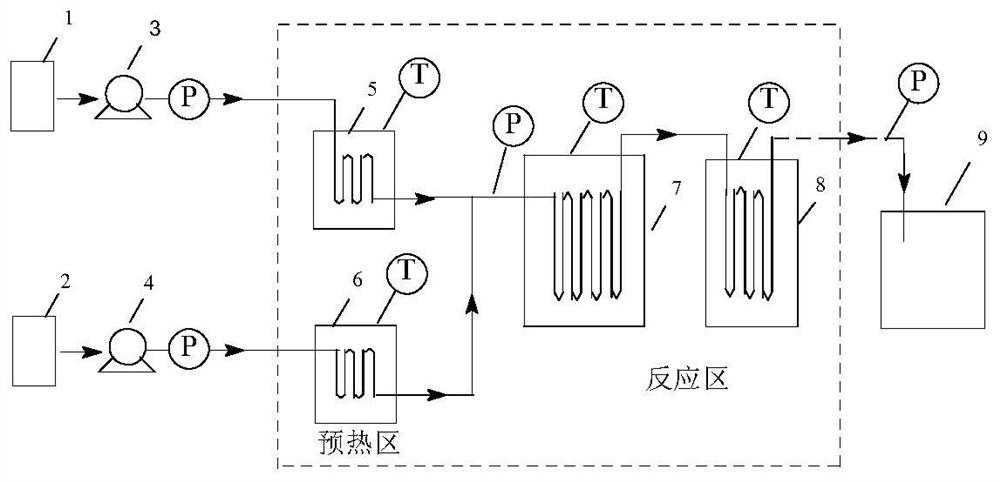

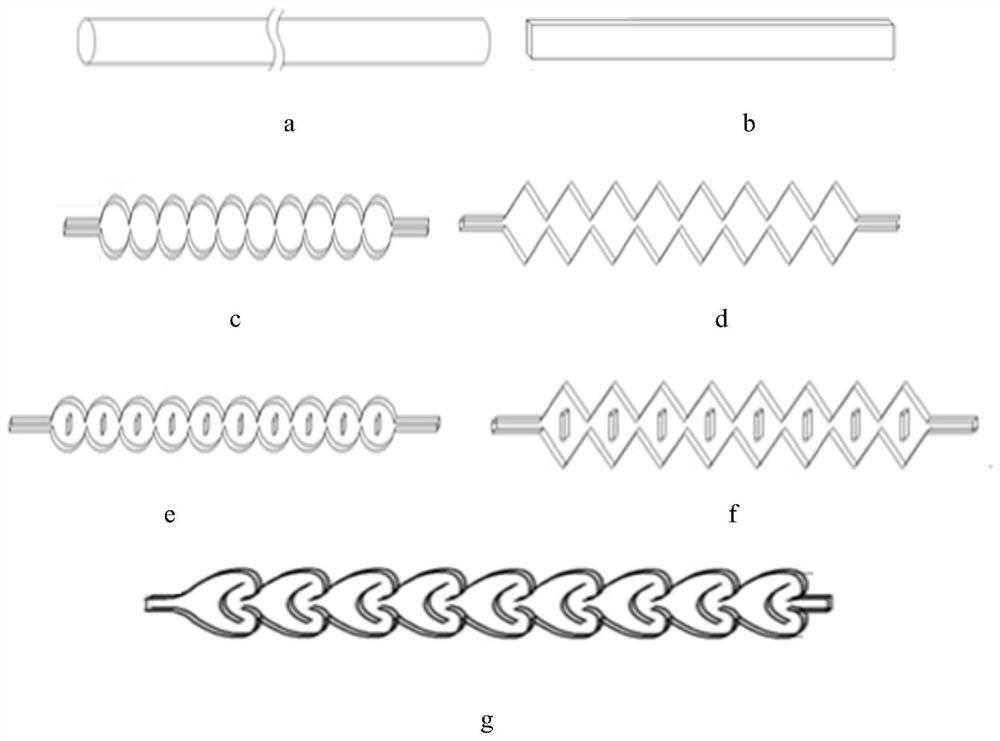

Embodiment 1

[0031] The microchannel reaction device of the present invention (the reaction device is assembled by 3a (front)+3b (back) channel structure) is divided into preheating zone, reaction zone and quenching zone, according to figure 2connect. By adjusting the flow rate (5-15ml / min) of the pump and the channel length of the microchannel, the reaction residence time is controlled to 180s, the preheating temperature and the reaction temperature are set to 60°C, and the reaction pressure is 5bar. The mixed solution of raw material benzoic acid and fuming sulfuric acid (104%) is passed through the preheating zone A of metering pump 1 input device, concentrated nitric acid (98%) is passed through the preheating zone B of pump 2 input device, fully After preheating, it enters the reaction zone for mixed reaction. Among them, the molar ratio of benzoic acid to concentrated nitric acid is 1:3, and the 3,5-dinitrobenzoic acid product is continuously discharged from the outlet, and the rea...

Embodiment 2

[0040] Microchannel reaction device (3a+3c) of the present invention is divided into preheating zone, reaction zone and quenching zone, according to figure 2 connect. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 210s, the flow rate of the pump is 5-15ml / min, the preheating temperature and the reaction temperature are set at 65°C, and the reaction pressure is 5bar. The mixed solution of raw material benzoic acid and fuming sulfuric acid (104%) is passed through the preheating zone A of metering pump 1 input device, concentrated nitric acid (98%) is passed through the preheating zone B of pump 2 input device, fully After preheating, it enters the reaction zone for mixed reaction. Among them, the molar ratio of benzoic acid to sulfuric acid is 1:6. The 3,5-dinitrobenzoic acid product is continuously discharged from the outlet, and the reaction solution is quenched with ice water, follow...

Embodiment 3

[0048] Microchannel reaction device (3a+3d) of the present invention is divided into preheating zone, reaction zone and quenching zone, according to figure 2 connect. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 240s, the flow rate of the pump is 5-15ml / min, the preheating temperature and the reaction temperature are set at 70°C, and the reaction pressure is 10bar. The mixed solution of raw material benzoic acid and fuming sulfuric acid (104%) is passed through the preheating zone A of metering pump 1 input device, concentrated nitric acid (98%) is passed through the preheating zone B of pump 2 input device, fully After preheating, it enters the reaction zone for mixed reaction. Wherein, the molar ratio of benzoic acid to sulfuric acid is 1:5, and the molar ratio of benzoic acid to nitric acid is 1:4. The 3,5-dinitrobenzoic acid product is continuously discharged from the outlet, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com