Method for preparing magnesium-aluminum composite plate by radio frequency magnetic control

A magnetic control, composite plate technology, applied in the field of light alloys, can solve the problems of difficult metallurgy and other problems, and achieve the effect of easy plate thickness, good interlayer bonding strength and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Substrate preparation: Soak the wire-cut magnesium alloy substrate (with a size of φ76.2×5mm) in an acetic acid solution with a mass concentration of 50wt% for 24 hours to remove oil stains on the surface, and then ultrasonically clean it three times with deionized water, each time The time is 15min, the ultrasonic frequency is 100Hz, and then polished to the mirror surface on one side. After polishing, they are respectively placed in acetone, ethanol and deionized water for ultrasonic cleaning. 100Hz;

[0034] (2) Then fix the magnesium alloy substrate cleaned in step (1) on the baffle, put it into the sample delivery chamber of the radio frequency magnetron sputtering equipment for vacuuming, and the vacuum degree is higher than 5×10 -3 Torr, then turn off the chamber vacuum pump;

[0035] (3) Target pre-sputtering: Pre-sputtering is performed on the magnesium target and the aluminum target in the sputtering chamber respectively, and the vacuum degree of the cham...

Embodiment 2

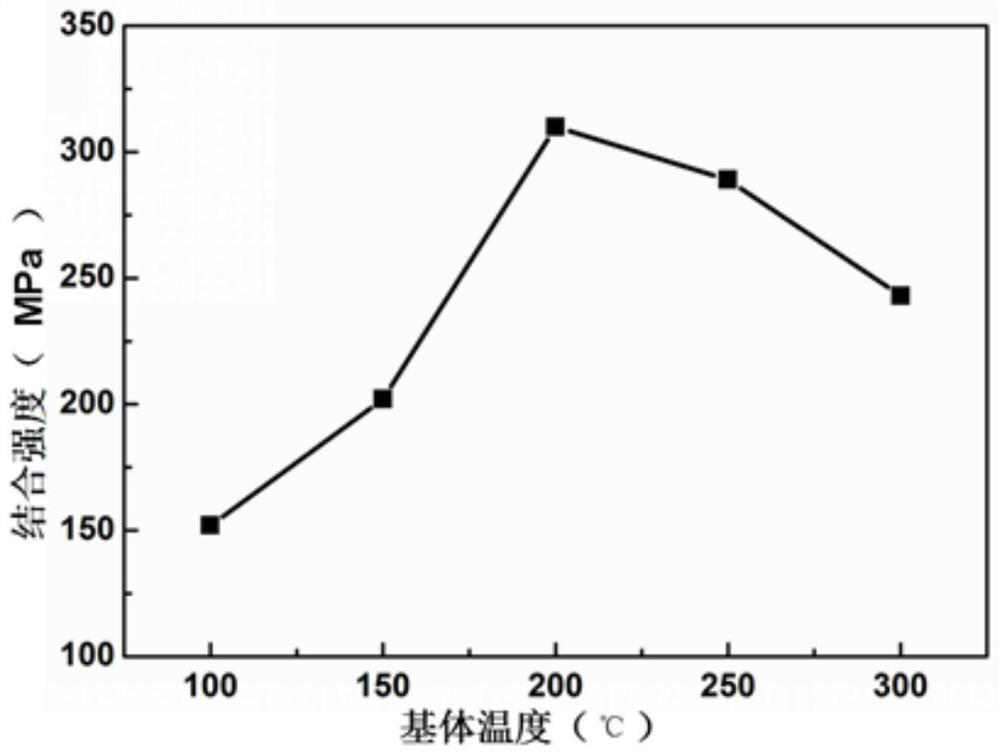

[0046] The preparation process is the same as in Example 1, except that the heating temperature of the magnesium alloy substrate in step (6) of Example 1 is replaced by 150°C.

[0047] The method for testing the interface bonding force of the magnesium-aluminum composite panel obtained in this example is the same as that in Example 1, and the interface bonding force is 202 MPa.

Embodiment 3

[0049] The preparation process is the same as that of Example 1, except that the heating temperature of the magnesium alloy substrate in step (6) of Example 1 is replaced by 200°C.

[0050] The method for testing the interfacial bonding force of the magnesium-aluminum composite panel obtained in this embodiment is the same as in Example 1, and the interfacial bonding force is 310 MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com