A kind of wood coating combination of heat transfer roller coating and preparation method thereof

A wood coating and thermal transfer technology, applied in the field of coatings, can solve the problems of difficult adhesion of thermal transfer patterns, inability to complete the thermal transfer process, and reduce the adhesion of topcoats, so as to reduce powder content and improve thermal transfer. Printing performance, the effect of improving the amount of paint applied by the roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

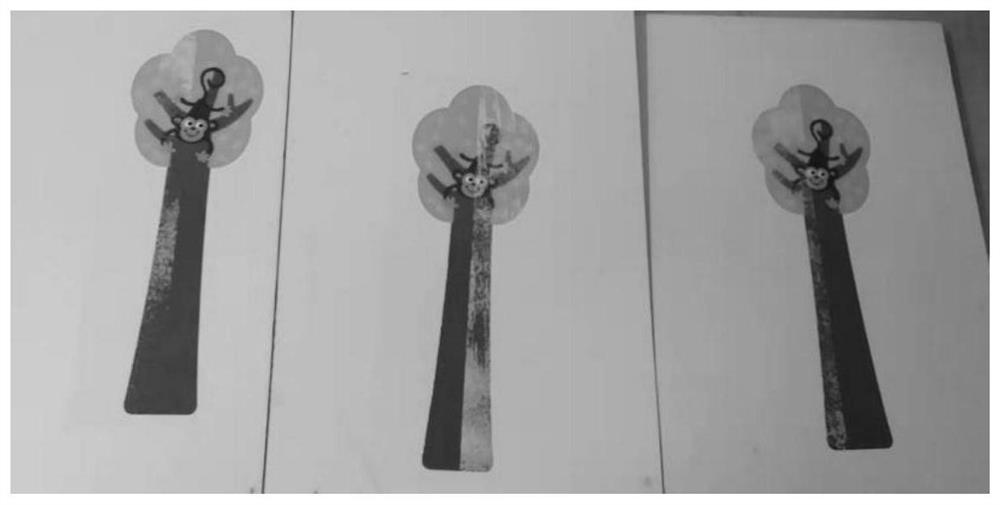

Image

Examples

preparation example Construction

[0149] The preparation method of roller coating white primer comprises the steps:

[0150] (1) Feeding in the first stage: Add the emulsion and water described in component A into the dispersion tank, then add the dispersant, wetting agent, defoamer, and pH regulator described in component A respectively, and stir to form For the mixture, the speed of mixing and stirring is controlled at 800-1000rpm, while maintaining dispersion for 10-15min, until the fineness is ≤40μm, enter the next stage;

[0151] (2) Feeding in the second stage: Add the titanium dioxide, talc powder, and heavy calcium powder described in component B into the dispersion tank described in step (1), and control the speed at 1500-2000 rpm, and use the frequency at 150-300 kHz, the power density can be 10~30w / L ultrasonic treatment, keep the dispersion for 15-20min, until the fineness is ≤50μm, enter the next stage;

[0152] (3) Feeding in the third stage: Add the mixed solution of film-forming aids, co-solve...

Embodiment 1

[0176] Example 1 Roller coating of white primer and Example 1 Roller coating of white topcoat, according to the national standard GB / T23999-2009, and GB24410-2009 testing, the performance meets the requirements of the national standard.

[0177] Construction technology of the present invention

[0178] Process 1: One base and one side, MDF——1 primer (pass 3 rollers)——dry at 35-40°C for 10 minutes—1 top coat (pass 3 rollers)—35- Dry at 40°C for 40 minutes——heat transfer printing at 200°C and press for 30 seconds——place at room temperature for 1 hour to release the mold.

[0179] Process 2: Two bottoms and one side, MDF——1 primer (pass 3 rollers)——dry at 35-40°C for 10 minutes—1 primer (pass 3 rollers)—35- Dry at 40°C for 10 minutes——1 coat of topcoat (through 3 rollers)——dry at 35-40°C for 40 minutes——heat transfer printing at 200°C and press for 30 seconds—place at room temperature for 1 hour to release the mold .

[0180] Process 3: Three bottoms and two sides, MDF - 1 pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com