Negative ion antibacterial coating and preparation method thereof

A negative ion antibacterial and negative ion technology, applied in the field of coatings, can solve problems such as power consumption and human body side effects, and achieve the effects of reducing electromagnetic radiation intensity, improving air quality, and improving indoor air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

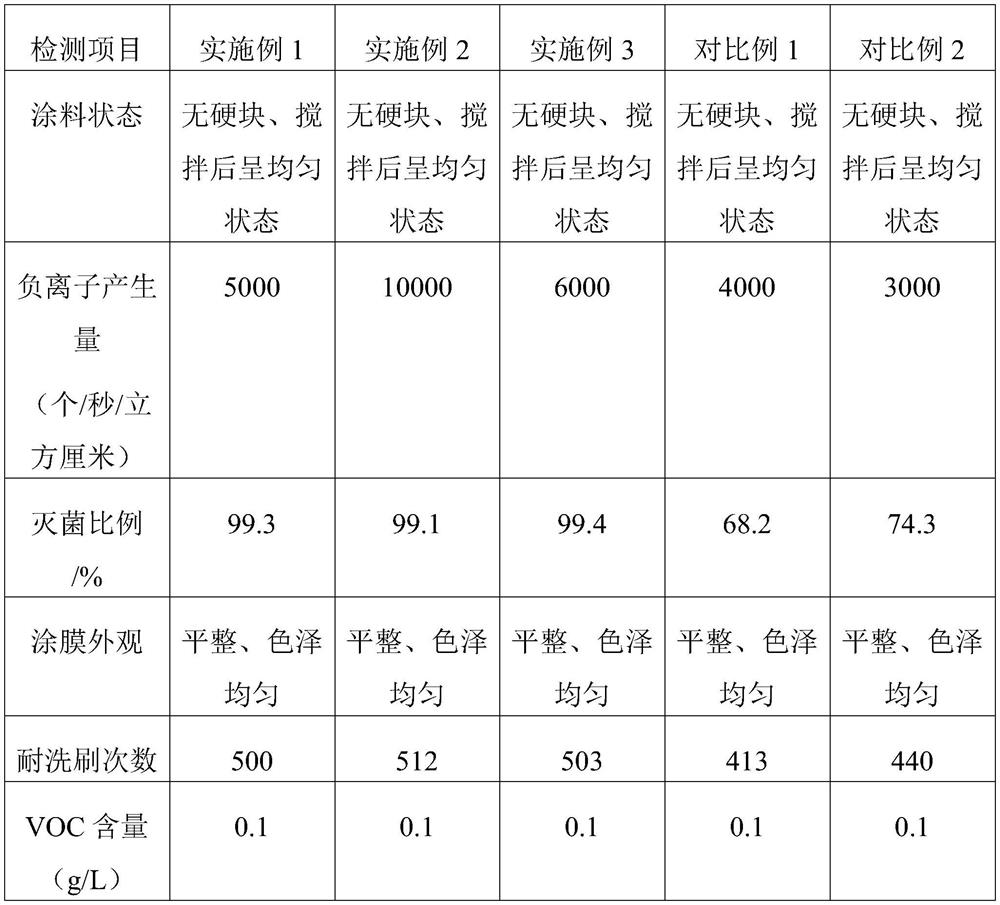

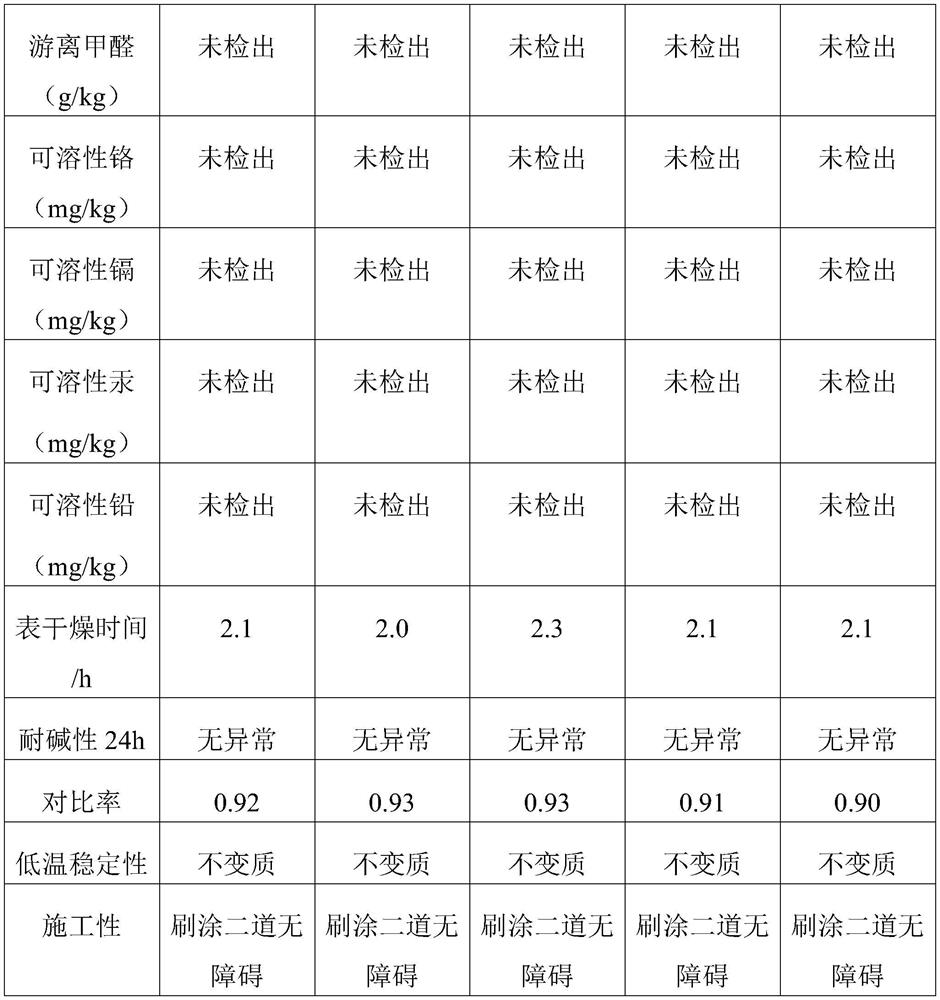

Examples

Embodiment 1

[0028] The present embodiment provides a kind of preparation method of negative ion antibacterial coating, comprises the steps:

[0029] (1) prepare camellia composite anion material, method is:

[0030] (1) Use a radioactive detector to screen nano-scale tourmaline to remove radioactive raw materials, and then pass the tourmaline through 2000 mesh, 4000 mesh, 6000 mesh graded grinding vibration screening and 2800r / min high-speed airflow to disperse the tourmaline The average particle size is 40nm;

[0031] (2) Take 1000g of tourmaline, mix it with 300g of hexagonalite and 65g of camellia leaf extract evenly under the condition of 80r / min.

[0032] (II) prepare negative ion antibacterial coating, method is:

[0033] (i) 5000g silicone modified acrylic resin, 1200g titanium dioxide, 400g sodium tripolyphosphate, 150g nano-zinc oxide, 100g ethylene glycol, 50g organic silicone oil, 50g mica sand powder, 300g camellia composite negative ion material and 1000g pure water Mix to...

Embodiment 2

[0036] The present embodiment provides a kind of preparation method of negative ion antibacterial coating, comprises the steps:

[0037] (1) prepare camellia composite anion material, method is:

[0038] (1) Use a radioactive detector to screen nano-scale tourmaline linearly to remove radioactive raw materials, and then pass the tourmaline through 2000 mesh, 4000 mesh, 6000 mesh graded grinding vibration screening and 2800r / min high-speed airflow to disperse the tourmaline The average particle size is 60nm;

[0039] (2) Take 1000g of tourmaline, mix it with 700g of hexagonalite and 170g of camellia extract evenly under the condition of 100r / min.

[0040] (II) prepare negative ion antibacterial coating, method is:

[0041] (i) 6000g silicone modified acrylic resin, 1600g titanium dioxide, 800g sodium tripolyphosphate, 250g nano-zinc oxide, 200g ethylene glycol, 100g organic silicone oil, 100g mica sand powder, 500g camellia composite anion material and 1500g pure water Mix t...

Embodiment 3

[0044] The present embodiment provides a kind of preparation method of negative ion antibacterial coating, comprises the steps:

[0045] (1) prepare camellia composite anion material, method is:

[0046] (1) Use a radioactive detector to screen nano-scale tourmaline linearly to remove radioactive raw materials, and then pass the tourmaline through 2000 mesh, 4000 mesh, 6000 mesh graded grinding vibration screening and 2800r / min high-speed airflow to disperse the tourmaline The average particle size is 50nm;

[0047] (2) Take 1000g of tourmaline, mix it with 500g of hexagonalite and 110g of camellia extract evenly under the condition of 90r / min.

[0048] (II) prepare negative ion antibacterial coating, method is:

[0049](i) 5500g silicone modified acrylic resin, 1400g titanium dioxide, 600g sodium tripolyphosphate, 200g nano-zinc oxide, 150g ethylene glycol, 75g organic silicone oil, 75g mica sand powder, 400g camellia composite negative ion material and 1200g pure water Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com