Faint yellow refrigeration coating as well as preparation method and application thereof

A technology of light yellow and yellow pigments, applied in the field of light yellow refrigeration coatings and its preparation, can solve the problems of inability to achieve refrigeration purposes, decrease in visible light spectrum reflectance, decrease in solar reflectance, etc., and achieve obvious passive energy saving effects and significant cooling effects , the effect of eliminating light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

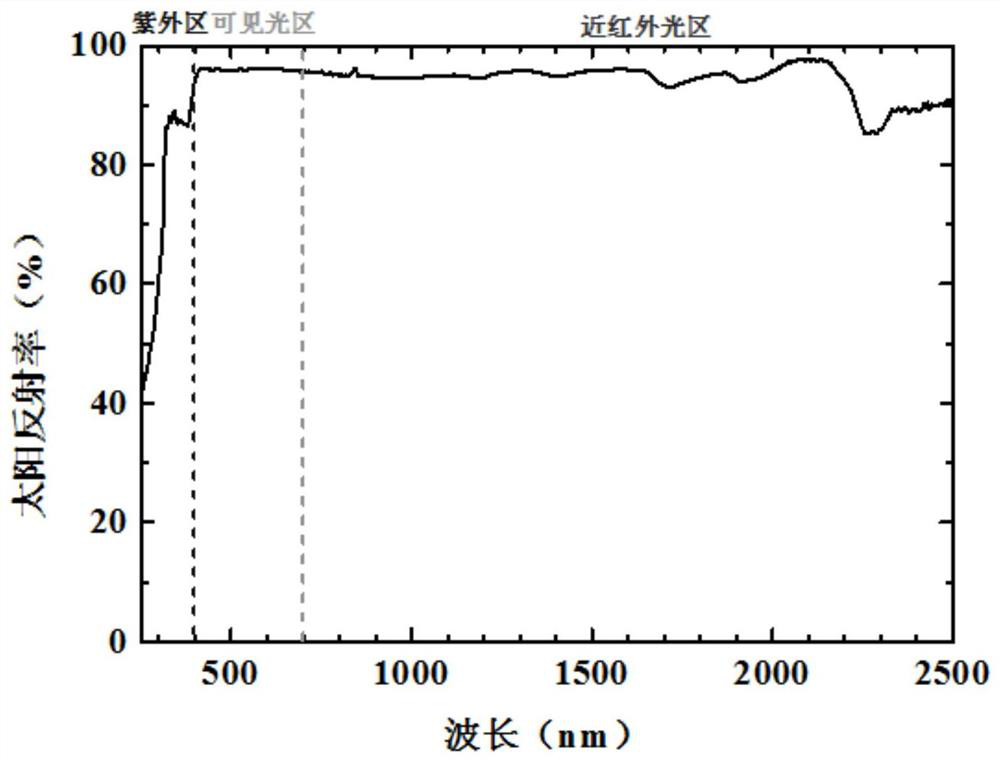

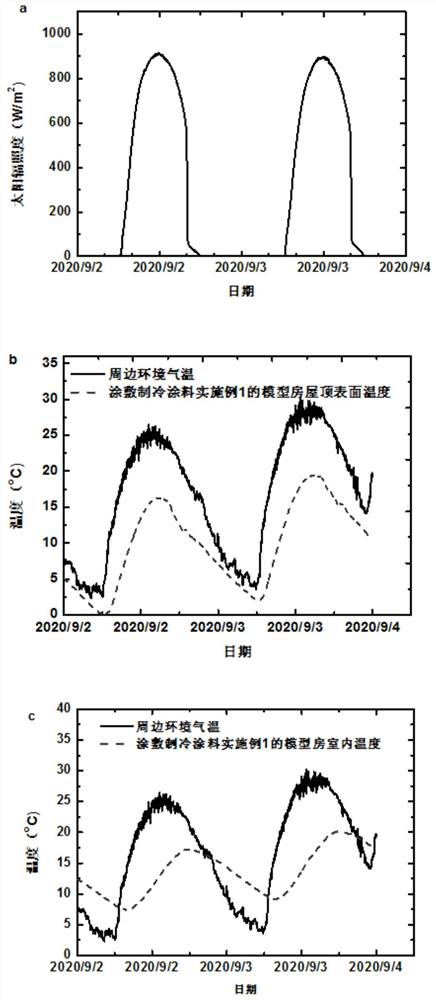

Embodiment 1

[0033] In the light yellow refrigeration paint of this embodiment, styrene-acrylic emulsion, purple light fluorescent powder, sky blue fluorescent powder, rutile titanium dioxide, titanium nickel yellow, water, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, polyoxyethylene The mass percent contents of ether defoamer, polyurethane thickening and leveling agent, and ester film-forming aids are respectively: 40%, 5%, 14%, 25%, 1%, 10%, 1%, 1%, 1% %, 1%, 1%.

[0034]Add styrene-acrylic emulsion, purple fluorescent powder, sky blue fluorescent powder, rutile titanium dioxide, titanium nickel yellow, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, polyether defoamer and water with grinding After mixing in a container of beads or glass beads, stir and disperse at a speed of 1100 rpm for 30 minutes, then press the dispersed mixture into a grinding tank for 30 minutes and grind it for 30 minutes, and...

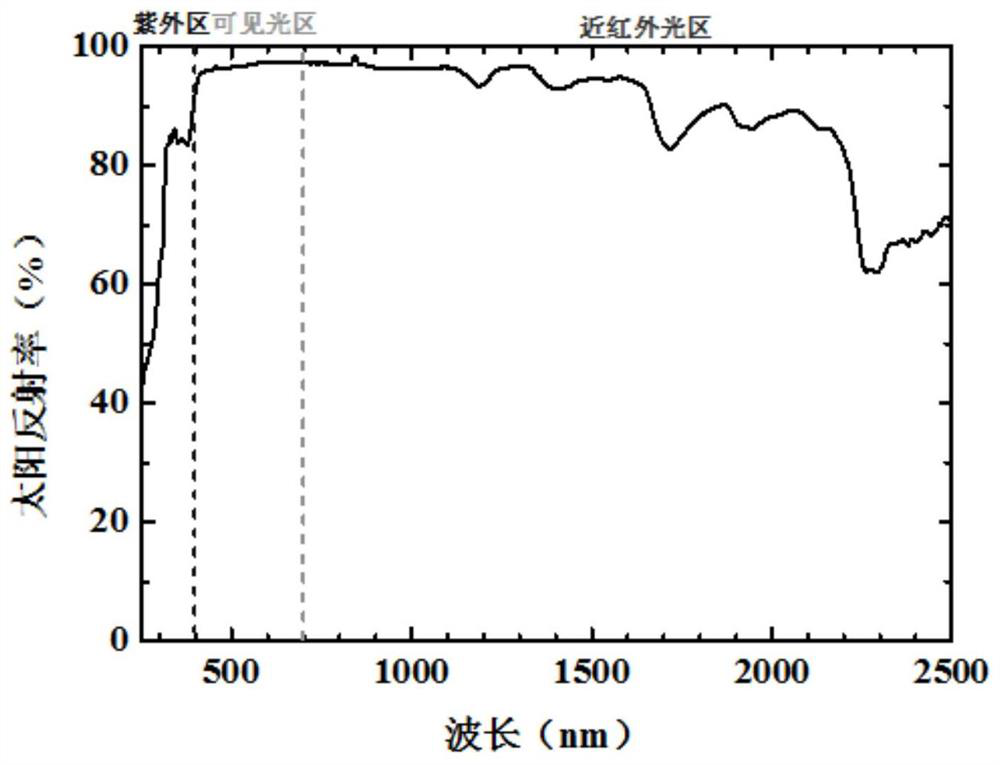

Embodiment 2

[0040] In the light yellow refrigeration paint of this embodiment, styrene-acrylic emulsion, purple light fluorescent powder, blue-green fluorescent powder, rutile titanium dioxide, titanium nickel yellow, water, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, The mass percent contents of polyether defoamer, polyurethane thickening and leveling agent, and ester film-forming aids are respectively: 45%, 3%, 12%, 26%, 2%, 10%, 0.4%, 0.4%, 0.4%, 0.4%, 0.4%.

[0041] Add styrene-acrylic emulsion, purple fluorescent powder, blue-green fluorescent powder, rutile titanium dioxide, titanium nickel yellow, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, polyether defoamer and water After mixing in a container of grinding beads or glass beads, stir at high speed (1200 rpm) and disperse for 30 minutes, then press the dispersed mixture into the grinding tank for 30 minutes and grind for 30 minutes, and ad...

Embodiment 3

[0047] In the light yellow refrigeration paint of this embodiment, styrene-acrylic emulsion, purple light fluorescent powder, yellow-green fluorescent powder, rutile titanium dioxide, titanium nickel yellow, water, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, The mass percentage contents of polyether defoamer, non-ionic thickening and leveling agent, and ester film-forming aids are respectively: 42%, 4%, 13%, 28%, 1%, 10%, 0.4%, 0.4% %, 0.4%, 0.4%, 0.4%.

[0048] Add styrene-acrylic emulsion, purple fluorescent powder, yellow-green fluorescent powder, rutile titanium dioxide, titanium nickel yellow, polycarboxylate ammonium salt dispersant, nonylphenol polyoxyethylene ether wetting agent, polyether defoamer and water After mixing in a container of grinding beads or glass beads, stir at a high speed (stirring rate 1000 rpm) and disperse for 30 minutes, then press the dispersed mixture into the grinding jar for grinding for 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com