A kind of coated product and preparation method thereof

A product and coating technology, applied in the direction of coating, etc., to achieve the effect of improving performance, increasing spectral reflectance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

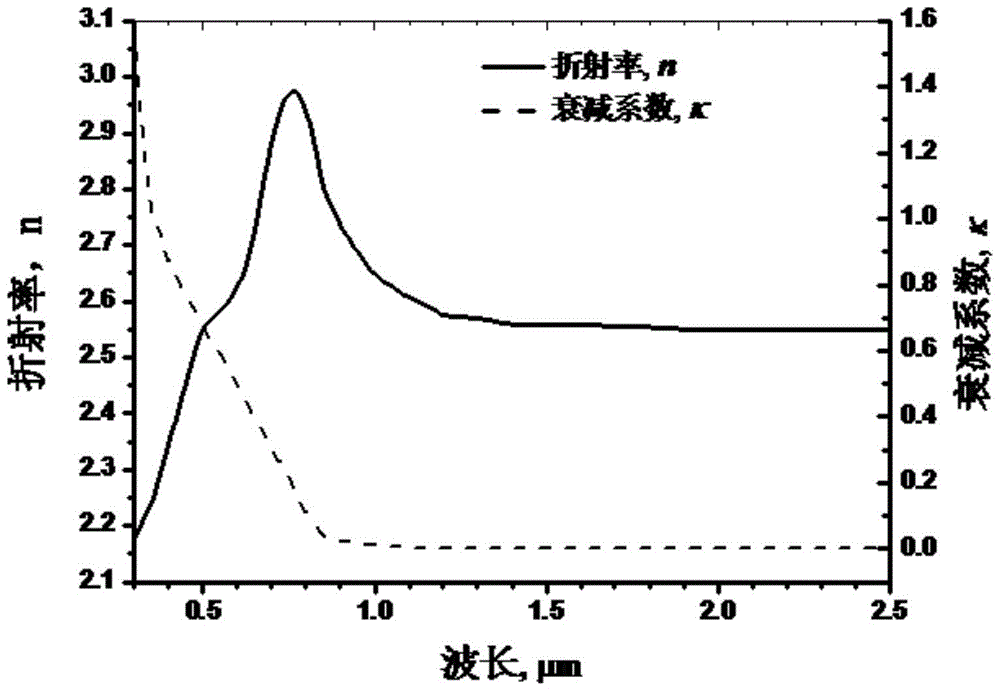

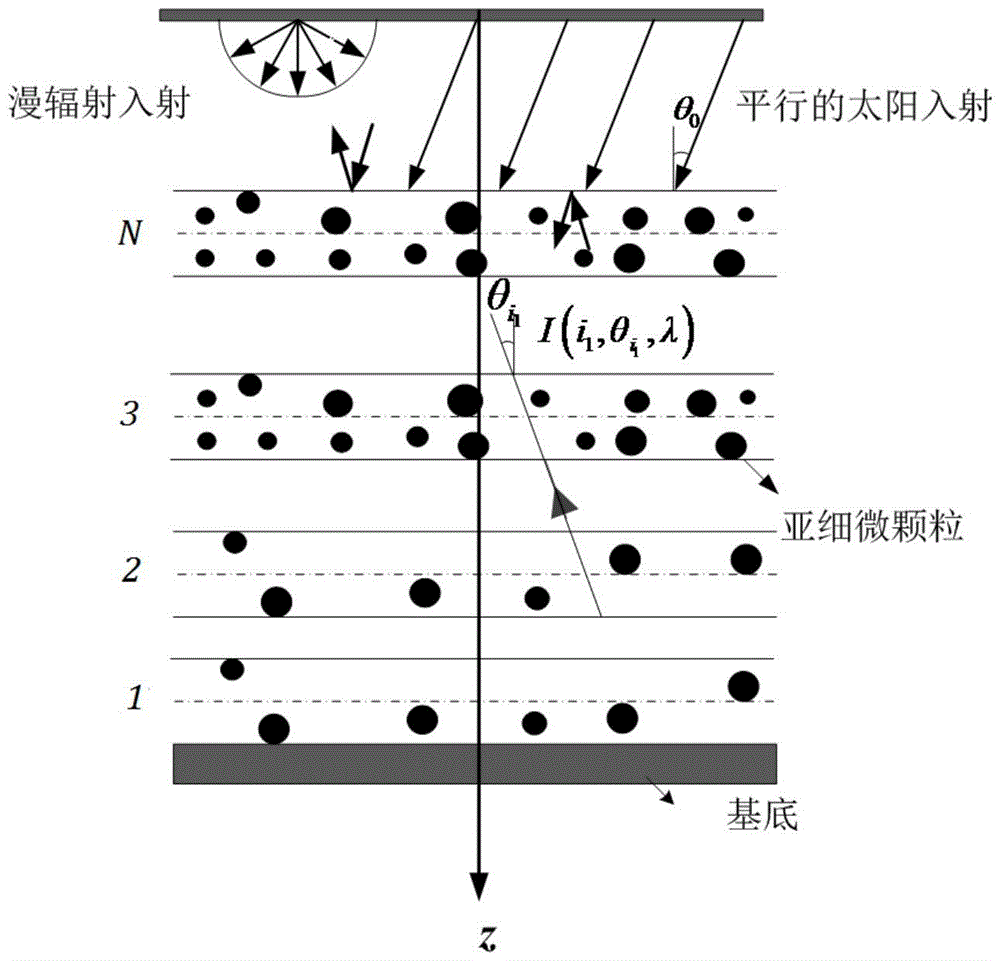

[0052] The preparation method of the paint is as follows: calculate the mass of copper oxide particles and acrylic resin required for the paint, then mix the dispersed phase copper oxide particles and resin evenly, and heat at a temperature of 70°C to 90°C to form a uniform and transparent paint. Sol.

[0053] The paint is sprayed on the base material in sequence to form a set thickness, and after drying, the coated product of the present invention is obtained.

Embodiment 1

[0055] The base material is a wall with a reflectivity of 1.0, the metal oxide particles are copper oxide particles with a diameter of 0.57 μm, and the scattering medium is acrylic resin. The coatings are the first coating and the second coating, the first coating and the second coating. The second coating is composed of copper oxide particles and acrylic resin, wherein the volume fraction of copper oxide is 0.5% and 4.5% respectively, and the thickness is 20 μm. The first coating covers the surface of the substrate, and the second coating covers the surface of the first coating.

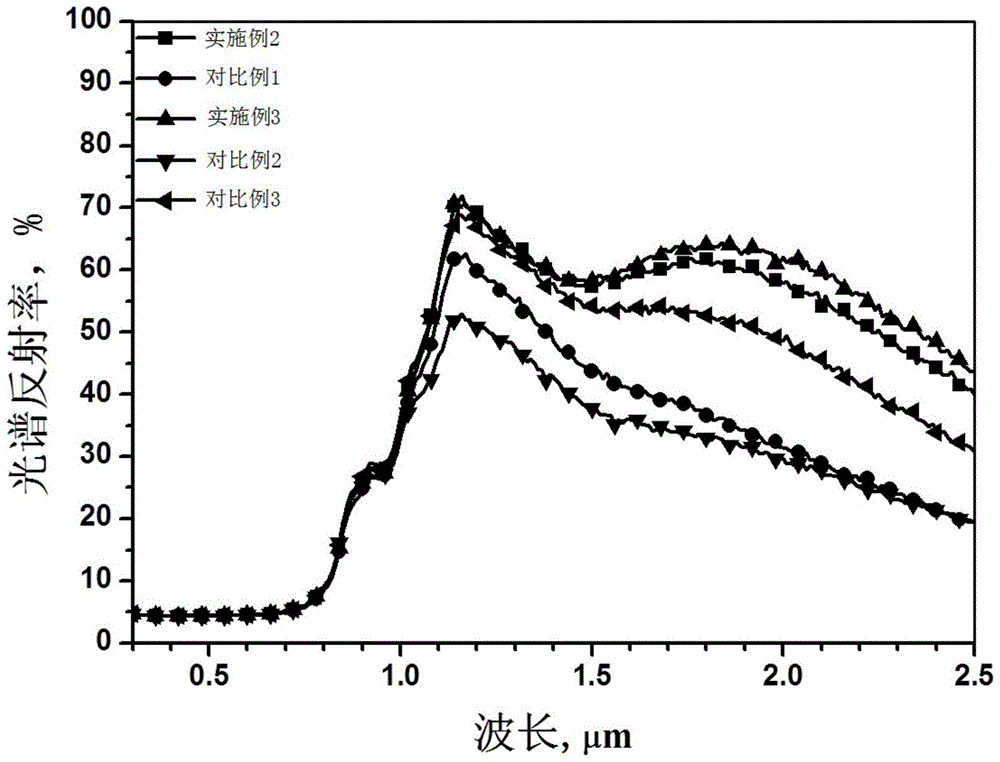

[0056] Using the I(λ) and h(λ) parameters in the literature, and calculating the spectral reflectance ρ(λ) through Mie theory, the optimized parameter R can be obtained by substituting it into equation (1) opt . The resulting coating material R opt The maximum value of is 19.80, which is nearly 30% higher than that of the coating with uniform volume fraction of copper oxide in the prior art under ...

Embodiment 2

[0058] Repeat Example 1, the difference is that the reflectance of the surface of the substrate is 0, the metal oxide particles are copper oxide particles with a diameter of 0.50 μm, and the coating is uniformly increased from the bottom to the top. For the coating, the volume fraction of the copper oxide particles at the bottom of the coating is 1%, the volume fraction of the copper oxide particles at the top of the coating is 4%, and the total thickness of the coating is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com