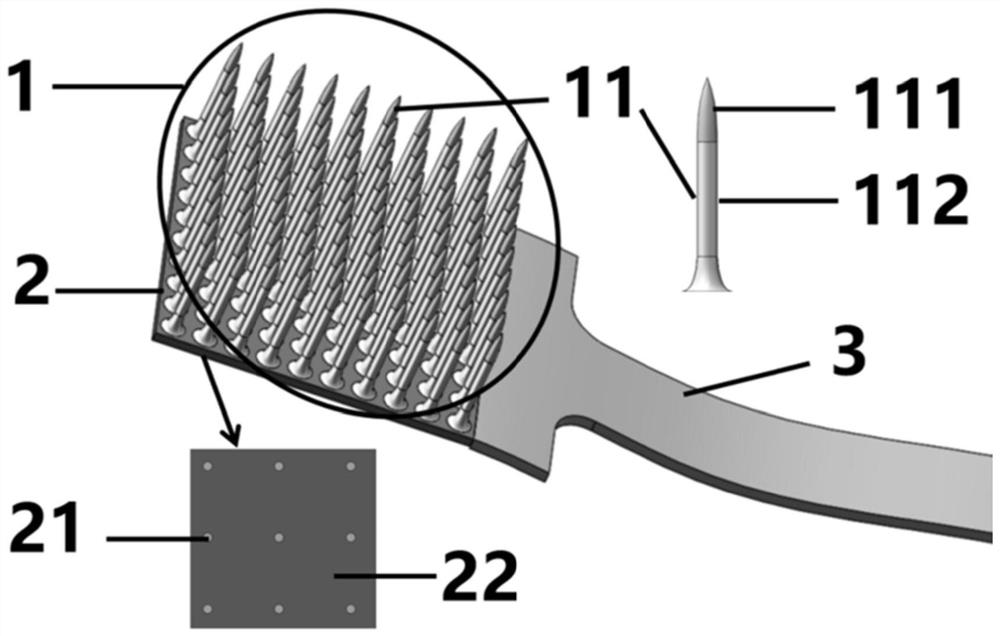

A microneedle array brain-computer interface device and its preparation method

A microneedle array, brain-computer interface technology, applied in the fields of electronics and biomedical engineering, can solve the problems of reducing the yield and uniformity of devices, optimizing process steps, time-consuming and laborious, etc., to promote development, simplify manufacturing processes, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

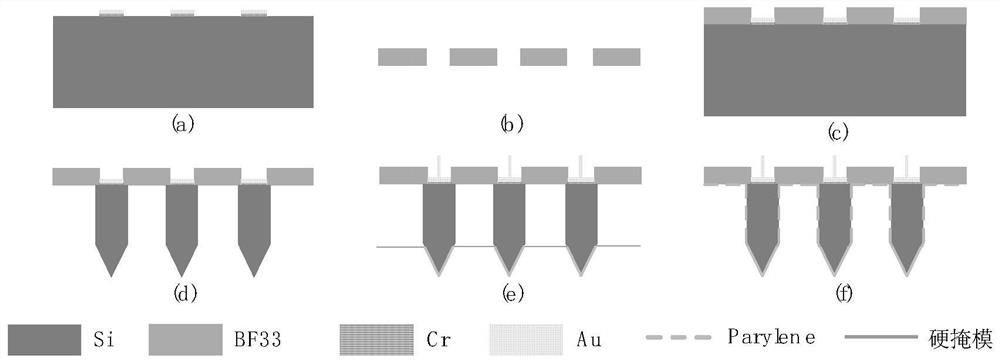

[0037] This embodiment provides a method for preparing a microneedle array type brain-computer interface device. The microneedle array layer is prepared with a non-metallic conductor, and the metal lead wire is processed by direct pressure welding.

[0038] Such as figure 2 As shown in (a), the microneedle array layer is prepared by using a low-resistance silicon wafer. After cleaning the silicon wafer, spin-coat photoresist with a thickness of 5um on the silicon wafer, pre-bake for 120s, expose for 45s, develop for 45s, rinse with deionized water for 30s, blow dry with nitrogen, and then sputter metal on the surface. Put the sputtered silicon wafer into an acetone solution to carry out the lift-off process, and finally obtain a metal pad on the upper surface of the silicon wafer; as a preferred method, the thickness of the low-resistance silicon wafer is 1.5mm, and the sputtered metal is chromium and gold.

[0039] Such as figure 2 As shown in (b), a glass sheet is used ...

Embodiment 2

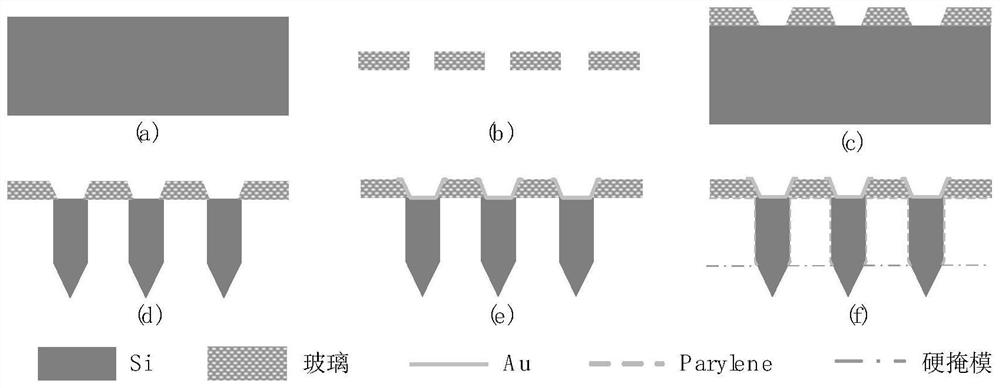

[0046] This embodiment provides a method for preparing a microneedle array type brain-computer interface device. The metal material is used as the microneedle array layer, and the metal lead wire is processed in the form of multi-layer metal interconnection. The following steps are specifically adopted:

[0047] Such as image 3 As shown in (a), the microneedle array layer is prepared by using a titanium sheet. Choose polished titanium sheet and wash it for later use.

[0048] Such as image 3 As shown in (b), a glass sheet is used as the insulating layer between the needles. Using high-precision laser machining through-glass via (TGV) technology to design the through-holes on the glass sheet, and prepare a number of through-holes distributed in an array on the glass sheet. As a preferred manner, the diameter of the through hole may be 10um-100um, and the thickness of the glass sheet is 300um.

[0049] Such as image 3 As shown in (c), the glass sheet and the titanium she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com