Aluminum alloy material and laser 3D printing aluminum alloy component based on same

A technology of aluminum alloy materials and aluminum alloy components, applied in the direction of additive processing, additive manufacturing, etc., can solve problems such as unsuitability for aluminum alloys, small liquid phase surface tension, etc., to prevent grain growth, refine grains, The effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

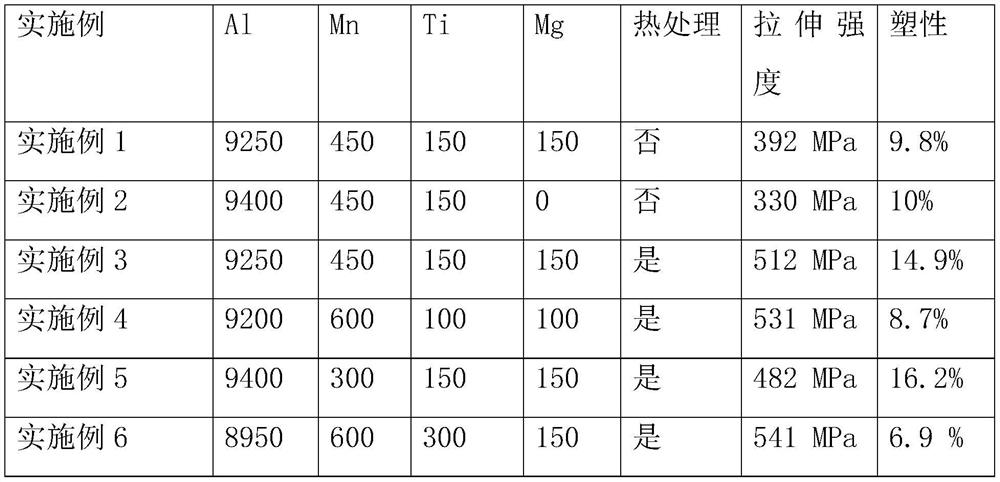

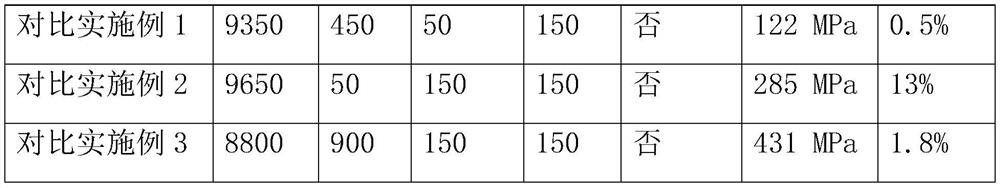

Examples

Embodiment 1

[0030] A laser 3D printing aluminum alloy component is 3D printed through the following steps:

[0031] (1) Design the three-dimensional model of the aluminum alloy component by using three-dimensional modeling software;

[0032] (2) configure the aluminum alloy material, mix 9250g Al, 450g Mn, 150g Ti, 150g Mg evenly to obtain the mixture powder, and use the gas atomization method to obtain the Al-Mn-Ti-Mg aluminum alloy powder after fully and uniformly melting, and the aluminum alloy The powder is sieved through a 200-mesh screen, and the sieved aluminum alloy powder is loaded into the powder feeding cylinder of the 3D printing equipment. After the cavity is sealed, it is vacuumed and filled with high-purity argon (≥99.99%) to make the oxygen If the content is less than 0.1%, preheat the substrate to 100°C;

[0033] (3) Laser forming is carried out according to the forming trajectory pre-designed by the 3D software. The printing parameters are: laser power 370W, scanning sp...

Embodiment 2

[0035] (1) Design the three-dimensional model of the aluminum alloy component by using three-dimensional modeling software;

[0036] (2) Configure aluminum alloy materials, mix 9400g Al, 450g Mn, and 150g Ti evenly to obtain mixture powder, and use gas atomization method to obtain Al-Mn-Ti aluminum alloy powder after fully and uniformly melting, pass the aluminum alloy powder through a 200-mesh sieve Mesh screening, put the screened aluminum alloy powder into the powder feeding cylinder of the 3D printing equipment, vacuumize the cavity and fill it with high-purity argon (≥99.99%), so that the oxygen content in the cavity is less than 0.1%, Preheat the substrate to 100°C;

[0037] (3) Laser forming is carried out according to the forming trajectory pre-designed by the 3D software. The printing parameters are: laser power 370W, scanning speed 1000mm / s, scanning distance 0.1mm, layer thickness 0.03mm.

Embodiment 3

[0039] (1) Design the three-dimensional model of the aluminum alloy component by using three-dimensional modeling software;

[0040] (2) Configure the aluminum alloy material, mix 9250g Al, 450g Mn, 150g Ti, 150g Mg uniformly to obtain the mixture powder, and use the gas atomization method to obtain the Al-Mn-Ti-Mg aluminum alloy powder after fully and uniformly melting, and the aluminum alloy The powder is screened through a 200-mesh screen, and the screened aluminum alloy powder is loaded into the powder feeding cylinder of the 3D printing equipment. After the cavity is sealed, it is vacuumed and filled with high-purity argon (≥99.99%) to make the oxygen in the cavity If the content is less than 0.1%, preheat the substrate to 100°C;

[0041] (3) Laser forming is carried out according to the forming trajectory pre-designed by the 3D software. The printing parameters are: laser power 370W, scanning speed 1000mm / s, scanning distance 0.1mm, layer thickness 0.03mm.

[0042] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com