A kind of lithium-based microwave dielectric ceramic material, its preparation method and lithium-based microwave dielectric ceramic

A technology of microwave dielectric ceramics and ceramic materials, applied in the field of materials, can solve the problems of easy ablation and deterioration of silver electrodes, and difficult matching and co-firing of silver electrodes, etc., achieve simple chemical composition and preparation process, improve frequency temperature coefficient, and improve sintering compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

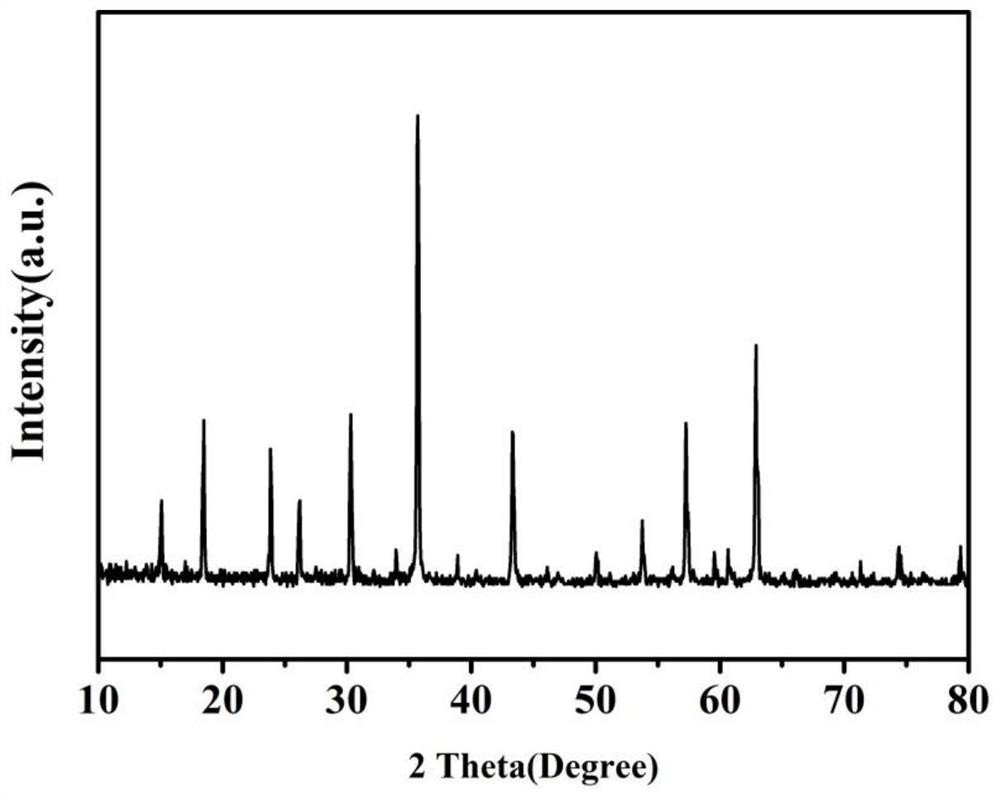

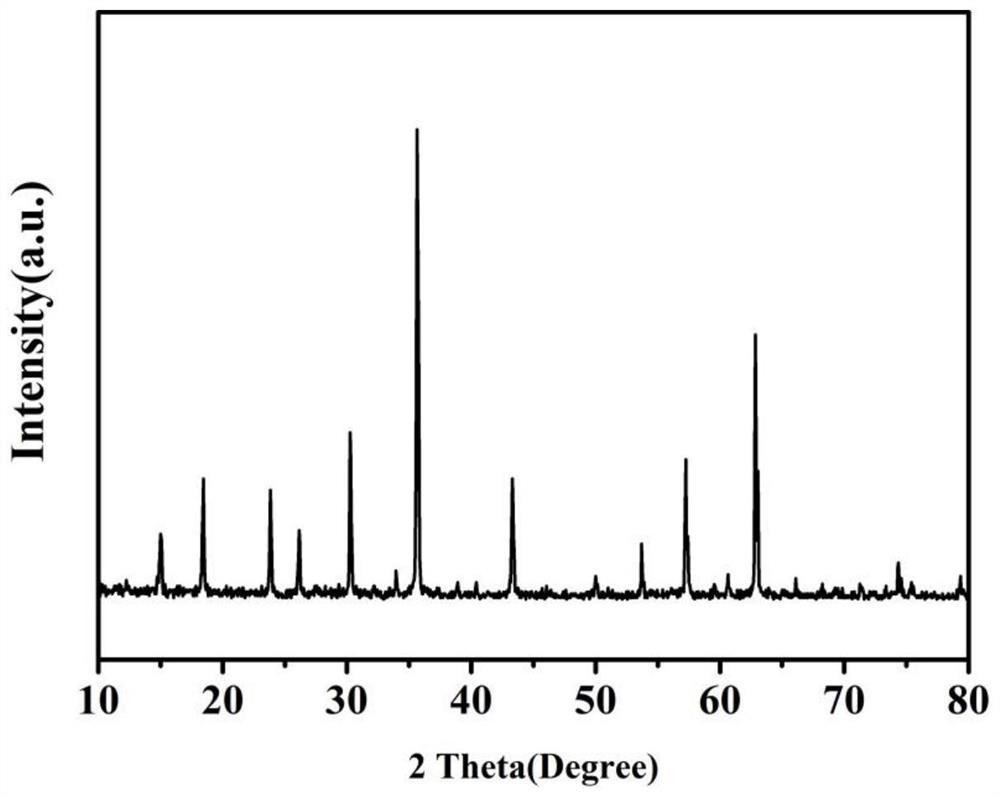

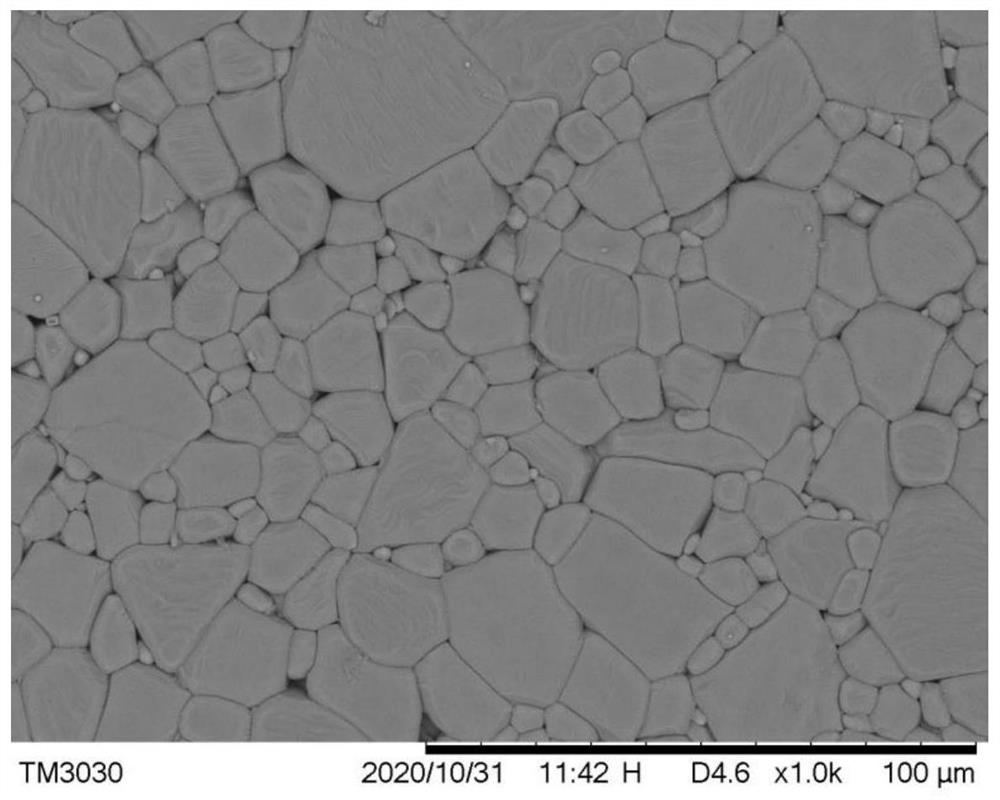

Image

Examples

preparation example Construction

[0044] The preparation method of the main powder shown in the formula (I) of the present invention is preferably specifically:

[0045] Li 2 CO 3 , ZnO, TiO 2 , CuO, MgO and Nb 2 o 5 It is obtained by mixing according to the metering ratio, wet grinding, drying, calcining and crushing.

[0046] Li of the present invention 2 CO 3 , ZnO, TiO 2 , CuO, MgO and Nb 2 o 5 The purity is ≥99%. The present invention does not limit its source, and it can be purchased commercially.

[0047] Firstly, the raw materials are pretreated, specifically ZnO and MgO.

[0048] The pretreatment specifically includes: ZnO is pre-fired at 600-700°C for 4-5 hours; preferably at 650-700°C for 4-4.5 hours; more preferably at 700°C for 4 hours;

[0049] MgO is kept at 700-800°C for 4-5h; preferably at 750-800°C for 4-4.5h; more preferably at 800°C for 4h;

[0050] The particle size of the MgO is 40-80nm.

[0051] Then to Li 2 CO 3 , ZnO, TiO 2 , CuO, MgO and Nb 2 o 5 Mix according to the...

Embodiment 1

[0102] A low-temperature sintered medium dielectric constant lithium-based microwave dielectric ceramic material and a preparation method thereof. The raw material of the lithium-based microwave dielectric ceramic material consists of main powder and auxiliary powder. The chemical formula of the main powder is: Li 2 (Zn (1-x) Cu x )(Ti (1-y) (Mg 1 / 3 Nb 2 / 3 ) y ) 3 o 8 , where 0≤x≤0.1, 0≤y≤0.2; additional auxiliary powders include glass frit accounting for 0.5-1.5% relative to the main powder and rutile-type TiO accounting for 5-10% relative to the main powder 2 Micronized. Wherein the glass powder is a mixture containing alkali metals and alkaline earth metals obtained by smelting and grinding Li 2 O-Al 2 o 3 -B 2 o 3 -ZnO-SiO 2 -Na 2 O-K 2 O-BaO-La 2 o 3 glass system. It is made by mixing in a ball mill, drying, granulating, molding and sintering.

[0103] 1) Synthesize the main powder: Li with purity ≥ 99% 2 CO 3 , ZnO, TiO 2 , CuO, MgO and Nb 2 o 5...

Embodiment 2

[0119] A low-temperature sintered medium dielectric constant lithium-based microwave dielectric ceramic and a preparation method thereof. The raw material of the lithium-based microwave dielectric ceramic is Li 2 (Zn (1-x) Cu x )(Ti (1-y) (Mg 1 / 3 Nb 2 / 3 ) y ) 3 o 8 Main powder and auxiliary powder Li 2 O-Al 2 o 3 -B 2 o 3 -ZnO-SiO 2 -Na 2 O-K 2 O-BaO-La 2 o 3 System glass powder and TiO 2 constitute.

[0120] 1) Synthesize the main powder: Li with purity ≥ 99% 2 CO 3 , ZnO, TiO 2 , CuO, MgO and Nb 2 o 5 As the main raw material, follow the steps below:

[0121] a. Raw material pretreatment: ZnO is pre-fired at 700°C for 4 hours, and MgO with a particle size of 40-80nm is pre-fired at 800°C for 4 hours for later use;

[0122] b. Ingredients weighing: according to Li 2 Zn(Ti 0.95 (Mg 1 / 3 Nb 2 / 3 ) 0.05 ) 3 o 8 To measure and weigh;

[0123] c. Wet ball milling: use pure water as the grinding liquid for the powder obtained in b, and ball mill for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com