Polyvinylidene fluoride ultrafiltration membrane and preparation method thereof

A polyvinylidene fluoride and ultrafiltration membrane technology, applied in the field of membrane separation, can solve the problems of affecting membrane flux, poor membrane hydrophilicity, poor membrane anti-pollution characteristics, etc., to increase hydrophilic groups and improve dispersion performance , increase the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

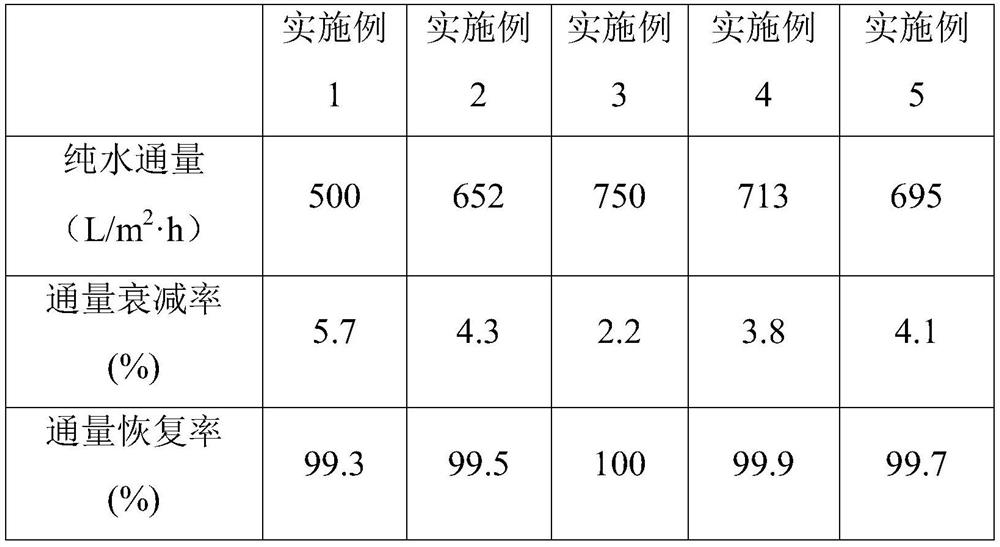

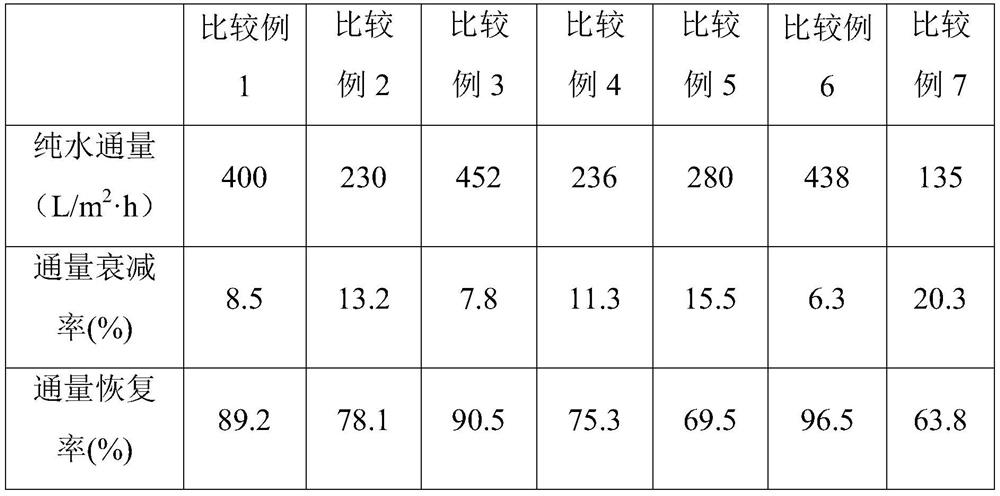

Examples

Embodiment 1

[0040] The following raw materials were weighed in parts by mass: 15 parts of PVDF resin, 2 parts of 2,2-dimethylolpropionic acid, 54 parts of nitrogen nitrogen dimethylacetamide, 5 parts of polyethylene glycol, polyoxyethylene sorbitan 1 part of monolaurate, 4 parts of sodium chloride, 5 parts of polyethyleneimine.

[0041] Dissolve 2,2-dimethylolpropionic acid in a small amount of ethanol, stir at 30°C for 5 minutes, and wait until it is uniformly dissolved for later use.

[0042] Pour nitrogen nitrogen dimethylacetamide into the reaction kettle, heat up to 70°C, add polyethylene glycol, stir at 10Hz for 5min; add polyoxyethylene sorbitan monolaurate, stir at 10Hz for 5min; Then add sodium chloride, stir at 20 Hz for 30 min; finally add PVDF resin and stir at 10 Hz for 30 min, and continue stirring at 20 Hz for 6 h. A homogeneous casting solution is formed.

[0043] Vacuum defoaming of the casting solution in the above steps for 10 hours at 50°C, and vacuum degassing of th...

Embodiment 2

[0047]Weigh the following raw materials in parts by mass: 17 parts of PVDF resin, 2 parts of 2,2-dimethylolpropionic acid, 59 parts of nitrogen nitrogen dimethylacetamide, 8 parts of hydrophilic agent, polyoxyethylene sorbitan mono 1 part of stearate, 5 parts of lithium chloride, 8 parts of polyethyleneimine.

[0048] Dissolve 2,2-dimethylolpropionic acid in a small amount of ethanol, stir at 40°C for 10 minutes, and wait until it is uniformly dissolved for later use.

[0049] Pour nitrogen nitrogen dimethylacetamide into the reaction kettle, heat up to 90°C, add hydrophilic agent, stir at 20Hz for 10min; add polyoxyethylene sorbitan monostearate, stir at 20Hz for 10min; Then add lithium chloride, stir at 30Hz for 60min; finally add PVDF resin and stir at 20Hz for 60min, and continue stirring at 30Hz for 10h. A homogeneous casting solution is formed.

[0050] Vacuum defoaming of the casting solution in the above steps for 10 hours at 80°C, and vacuum degassing of the core so...

Embodiment 3

[0055] Weigh the following raw materials in parts by mass: 18 parts of PVDF resin, 2 parts of 2,2-dimethylol butyric acid, 63 parts of nitrogen nitrogen dimethylformamide, 10 parts of absolute ethanol, polyoxyethylene sorbitan mono 2 parts of palmitate, 5 parts of calcium chloride, 10 parts of polyethyleneimine.

[0056] Dissolve 2,2-dimethylolbutyric acid in a small amount of ethanol, stir at 35°C for 7 minutes, and wait for uniform dissolution before use.

[0057] Pour nitrogen nitrogen dimethylformamide into the reaction kettle, heat up to 80°C, add absolute ethanol, stir at 15Hz for 7min; add polyoxyethylene sorbitan monopalmitate, stir at 15Hz for 7min; Add calcium chloride, stir at 15Hz for 7min; finally add PVDF resin and stir at 15Hz for 45min, and continue stirring at 25Hz for 8h. A homogeneous casting solution is formed.

[0058] Vacuum defoaming of the casting solution in the above steps for 13 hours at 65°C, and vacuum degassing of the core solution at 45°C for 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com