Electrochemical preparation method of p-aminophenyl-beta-hydroxyethyl sulfone

A technology of hydroxyethyl sulfone and aminophenyl, which is applied in the field of electrochemical preparation of p-aminophenyl-β-hydroxyethyl sulfone, can solve the problems of polluted environment, low product yield and high production cost, and achieves the reaction Mild conditions, selectivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

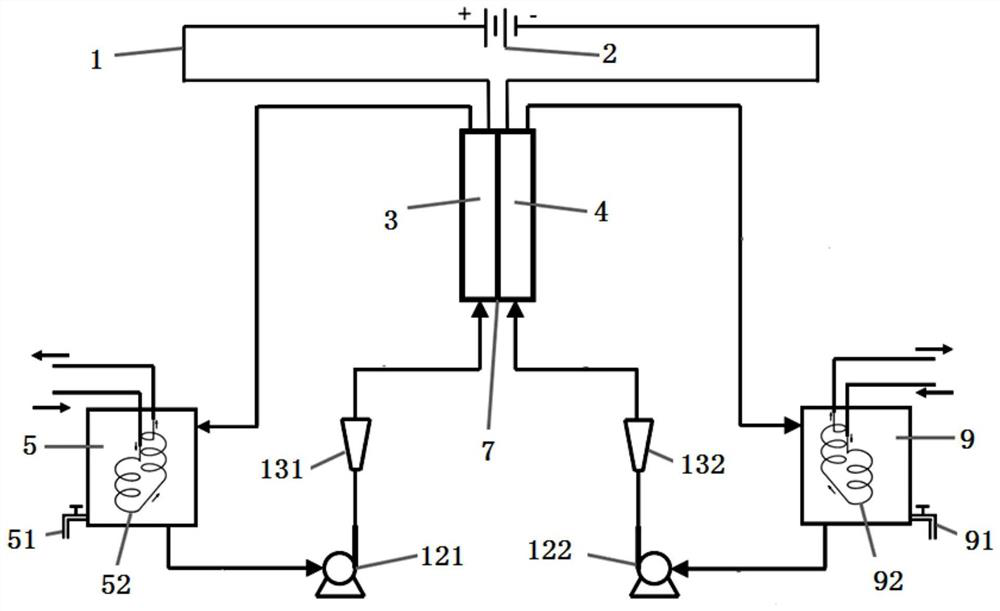

[0057] An H-type electrolytic cell is used as the reactor, the anode plate 3 is an anode plated titanium mesh, the cathode plate 4 is a cathode lead plate, and the cation membrane 7 is a cation exchange membrane Nafion PFSA Membranes (N-324).

[0058] The concentration of 1.5mol·L was added to the cathode compartment and anode compartment respectively. -1 250ml of sulfuric acid solution, and add 5g raw material p-nitrophenyl-β-hydroxyethyl sulfone (the raw material is provided by Henan Nayu New Material Co., Ltd., the purity is ≥98%.) in the cathode chamber, that is, 20g·L -1 , stirred and heated to 60°C with circulating water to maintain a constant temperature. After the raw materials were basically dissolved, electrolysis was started. Electrolysis was performed at a constant current of 0.74A, and the current density was 300A m -2 , when the incoming electricity reaches 7.2F·mol -1 Then, the reaction time was 338min, and the electricity was stopped, and the catholyte was ana...

Embodiment 2

[0072] An H-type electrolytic cell is used as the reactor, the anode plate 3 is an anode plated titanium mesh, the cathode plate 4 is a cathode copper plate, and the cation membrane 7 is a cation exchange membrane Nafion PFSA Membranes (N-324).

[0073] The concentration of 1.5mol·L was added to the cathode compartment and anode compartment respectively. -1 250ml of sulfuric acid solution, and 5g of raw material p-nitrophenyl-β-hydroxyethyl sulfone was added to the cathode chamber, that is, 20g L -1 , stirred and heated to 60°C with circulating water to maintain a constant temperature. After the raw materials were basically dissolved, electrolysis was started. Electrolysis was performed at a constant current of 1.23A, and the current density was 500A m -2 , when the incoming electricity reaches 6F·mol -1 After that, the reaction time was 282 min, the electricity was stopped, the catholyte was analyzed by high performance liquid chromatography, the current efficiency was 68.89...

Embodiment 3

[0075] An H-type electrolytic cell is used as the reactor, the anode plate 3 is an anode plated titanium mesh, the cathode plate 4 is a cathode lead plate, and the cation membrane 7 is a cation exchange membrane Nafion PFSA Membranes (N-324).

[0076] The concentration of 1.5mol·L was added to the cathode compartment and anode compartment respectively. -1 250ml of sulfuric acid solution, and 5g of raw material p-nitrophenyl-β-hydroxyethyl sulfone was added to the cathode chamber, that is, 20g L -1 , and 5g (2w%) of titanium sulfate, stirred and heated to 65°C with circulating water to maintain a constant temperature, after the raw materials were basically dissolved, electrolysis was started, and electrolysis was performed at a constant current of 0.74A, and the current density was 300A m -2 , when the incoming electricity reaches 6F·mol-1 After that, the reaction time was 282 min, the electricity was stopped, and the catholyte was analyzed by high performance liquid chromatogr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com