Method for enriching n-3 polyunsaturated fatty acids by enzymic method

An unsaturated fatty acid, n-3 technology, applied in the field of oil deep processing, can solve the problem of insufficient precision and achieve the effect of low fatty acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

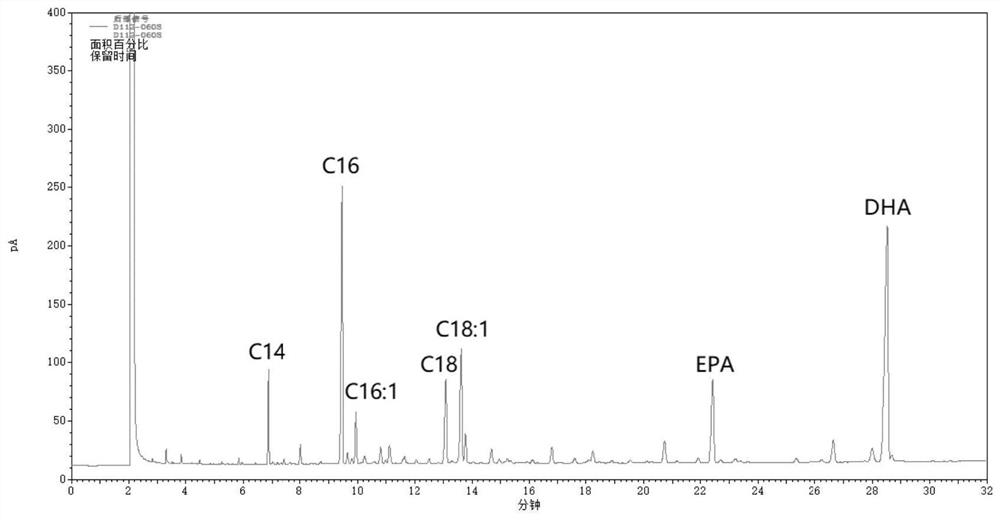

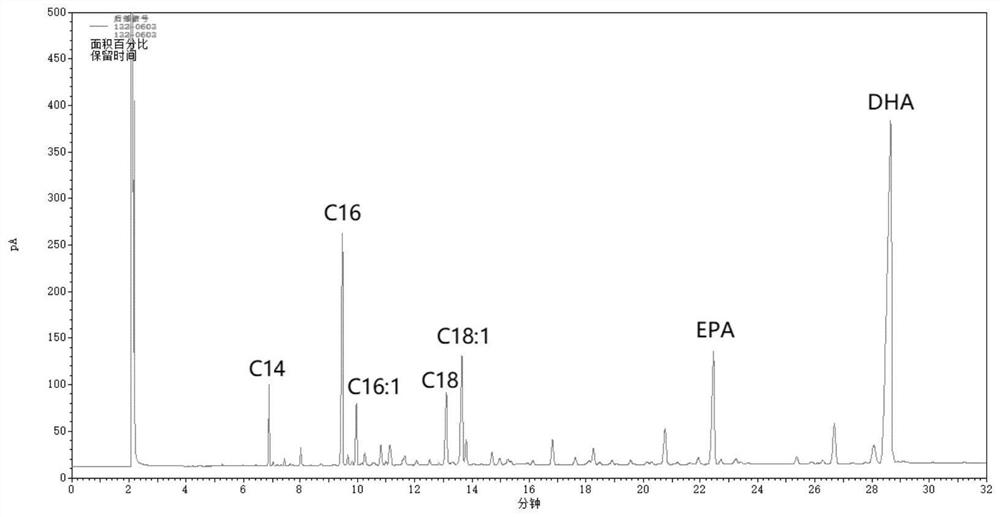

[0043] Accurately weigh the fish oil (the fatty acid composition of the fish oil sample is as follows: figure 1 Shown, wherein n-3PUFA=34.3%, SFA%=36.3%, MUFA%=24.0%) 3.0g, phosphate buffer solution 3g (concentration is 0.1mol / L, pH is 7) and AY "Amano" 400SD lipase 960U, added to the reaction kettle, put into the magnetic rotor, and sealed. The reaction kettle was placed on a magnetic stirrer, and the reaction kettle was connected to circulating water, and the water temperature was kept at a constant temperature of 37° C. for 10 hours. After the reaction, use KOH-ethanol aqueous solution to remove the hydrolyzed free fatty acid, then wash it with water three times, take the upper clear oil phase, and evaporate the solvent to obtain fish oil glycerides rich in n-3PUFAs (fatty acid composition such as figure 2 ).

[0044] Accurately weigh 10.0g of the obtained glyceride (the product accumulated many times in the previous step), 5g of ethanol solution (alcohol-water mass rati...

Embodiment 2

[0046] Accurately weigh 10.0 g of fish oil, 5 g of ethanol solution (alcohol-water mass ratio 1:4) and 4500 U of Candida antarcticalipase A lipase, add them into the reaction kettle, put it into a magnetic rotor, and seal it. The reaction kettle was placed on a magnetic stirrer, and the reaction kettle was connected to circulating water, and the water temperature was kept at a constant temperature of 37° C. for 10 hours. After reaction finishes, molecular distillation removes free fatty acid and ethyl ester in the product, obtains the fish oil glyceride that is rich in n-3PUFAs (fatty acid composition such as Figure 4 ).

[0047] Accurately weigh 3.0 g of glyceride, 3 g of phosphate buffer solution and 960 U of AY "Amano" 400SD lipase, add them into the reaction kettle, put it into the magnetic rotor, and seal it. The reaction kettle was placed on a magnetic stirrer, and the reaction kettle was connected to circulating water, and the water temperature was kept at a constant ...

Embodiment 3

[0049] Accurately weigh 3.0g of fish oil, 3.0g of phosphate buffer solution, 960U of AY "Amano" 400SD lipase and 1350U of Candidaantarctica lipase A lipase, add them into the reaction kettle, put it into the magnetic rotor, and seal it. The reaction kettle was placed on a magnetic stirrer, and the reaction kettle was connected to circulating water, and the water temperature was kept at a constant temperature of 37° C. for 10 hours. After the reaction, use KOH-ethanol aqueous solution to remove the hydrolyzed free fatty acid, then wash with water three times, take the upper clear oil phase, evaporate the solvent to obtain fish oil glyceride rich in n-3PUFA. In the fatty acid composition of glyceride products, the content changes of n-3PUFA, SFA and MUFA are shown in Table 1.

[0050] The experimental conditions and results of Examples 4 to 19 are shown in Table 1 below, wherein, except for the conditions indicated, the remaining operating parameters of Examples 4, 6, 8, 11, 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com