Porous carbon with uniform nano aperture as well as preparation method thereof and application

A porous carbon and nanotechnology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low specific surface area, can not promote anode biofilm well, achieve simple preparation method, suitable for microbial growth, promote biological The effect of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of biofuel cell (MFC):

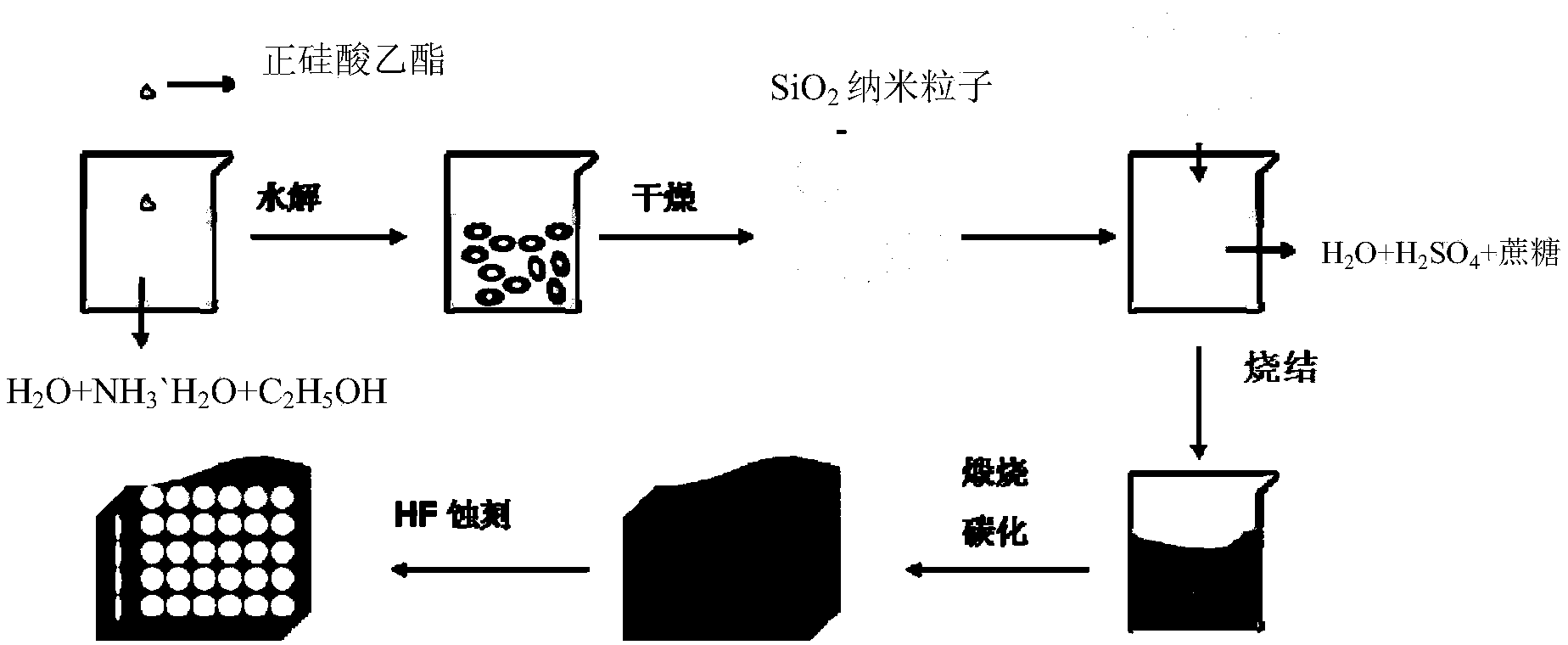

[0042] (1) Preparation method of porous carbon with uniform nanopore size, such as figure 1 shown, including the following steps:

[0043] (1) Mix 10mL of ammonia water, 40mL of absolute ethanol and 11mL of deionized water under magnetic stirring at room temperature for 3 minutes to obtain a mixed solution, then add 10mL of tetraethyl orthosilicate (14-15% by volume) dropwise into the mixed solution, The dropping rate is 0.1mL / s, react for 24h after the dropwise addition, and then dry at 70°C for 5h to obtain nanosphere SiO 2 template;

[0044] (2) 1.5g of nanosphere SiO obtained in step (1) 2 The template was added to the sucrose acidic solution (containing 2.0g sucrose, 0.2mL concentrated sulfuric acid, 12mL deionized water), and then sintered at 120°C for 6h, and then sintered at 150°C for 6h, and finally the solid was ground and put into the porcelain ark. Calcined at 850°C for 2 hours under argon atmosphere in the furnace to...

Embodiment 2

[0050] Preparation of biofuel cell (MFC):

[0051] (1) A method for preparing porous carbon with uniform nanopore size, comprising the following steps:

[0052] (1) Mix 5mL of ammonia water, 20mL of absolute ethanol and 5.5mL of deionized water under magnetic stirring at room temperature for 3 minutes to obtain a mixed solution, then add 5.3mL of tetraethyl orthosilicate (volume fraction: 14-15%) dropwise into the mixed solution , the dropping rate was 0.05mL / s, after the dropwise addition was completed, reacted for 18h, and then dried at 70°C for 3h to obtain nanospheres of SiO 2 template;

[0053] (2) Add 0.8g of nanosphere SiO obtained in step (1) 2 The template was added to the sucrose acidic solution (containing 1.5g sucrose, 0.15mL concentrated sulfuric acid, 10mL deionized water), then sintered at 100°C for 8h, and then sintered at 120°C for 8h, and finally put the solid into the porcelain ark after grinding. Calcined at 900°C for 2 hours under argon atmosphere in th...

Embodiment 3

[0059] Preparation of biofuel cell (MFC):

[0060] (1) A method for preparing porous carbon with uniform nanopore size, comprising the following steps:

[0061] (1) Mix 20mL of ammonia water, 80mL of absolute ethanol and 22mL of deionized water under magnetic stirring for 3 minutes at room temperature to obtain a mixed solution, then add 20mL of tetraethyl orthosilicate (14-15% by volume) dropwise into the mixed solution, The dropping rate is 0.2mL / s, react for 24h after the dropwise addition, and then dry at 90°C for 3h to obtain nanosphere SiO 2 template;

[0062] (2) Add 2 g of the nanosphere SiO obtained in step (1) 2 The template was added to the sucrose acidic solution (containing 2.5g sucrose, 0.5mL concentrated sulfuric acid, 15mL deionized water), then sintered at 120°C for 8h, and then sintered at 150°C for 8h, and finally put the solid into the porcelain ark after grinding. Calcined at 800°C for 4 hours under argon atmosphere in the furnace to obtain powder;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com