Lithium negative electrode coated with LiF film as well as preparation method and application of lithium negative electrode

A technology of lithium negative electrode and thin film, which is applied in the field of lithium negative electrode coated with LiF thin film and its preparation, can solve the problems of high physiological toxicity, high price of fluorinated reagents, degradation of mechanical properties and electronic conductivity, etc., and achieve improvement of interface characteristics, raw materials Inexpensive, promotes uniform deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Five ml of triethylamine trihydrofluoric acid is dissolved in 50 mL of tetrahydrofuran under a sealing condition, poured into the polytetrafluoroethylene reaction kettle, preheated at 35 ° C for 15 min, and salivate trihydrofluoric acid Tetrahydrofuran solution;

[0035] 2. Under the inert atmosphere, the polished pure lithium metal sheet is placed in a tetrahydrofuran solution of triethylamine trihydrofluoric acid, and the polytetrafluoroethylene reactor reaction is 2 h; then after the solvent is washed with tetrahydrofuran, drying at 100 ° C 1H, the lithium negative electrode of the LIF film was obtained.

[0036] The resulting two lithium negative components of the two coated LIF films were partyed as symmetrical. The lithium negative electrode and commercial lithium negative electrode of the obtained coated LIF film is loaded into a metal lithium half cell. Press the assembled symmetrical battery to 5mAH. cm -2 The capacity density is 5 mA. cm -2 The current density ...

Embodiment 2

[0039] 1. 5 ml of pyridine hydrogenide is dissolved in 50 mL of tetrahydrofuran and poured into the polytetrafluoride reaction kettle, 45 ° C for 10 min.

[0040] 2. Under an inert atmosphere, the foam-composite metal lithium is placed in the fluorinated reagent obtained from S1, and the reaction 2H is reacted at the polytetrafluoroethylene reactor;

[0041] 3. After cleaning the lithium tetrahydrofuran of the reaction, drying at 100 ° C for 1 h to prepare a lithium negative electrode coating the LIF film.

[0042] 4. Filled the resulting lithium sheet into a symmetrical battery and assembles the resulting lithium sheet into a metal lithium half cell.

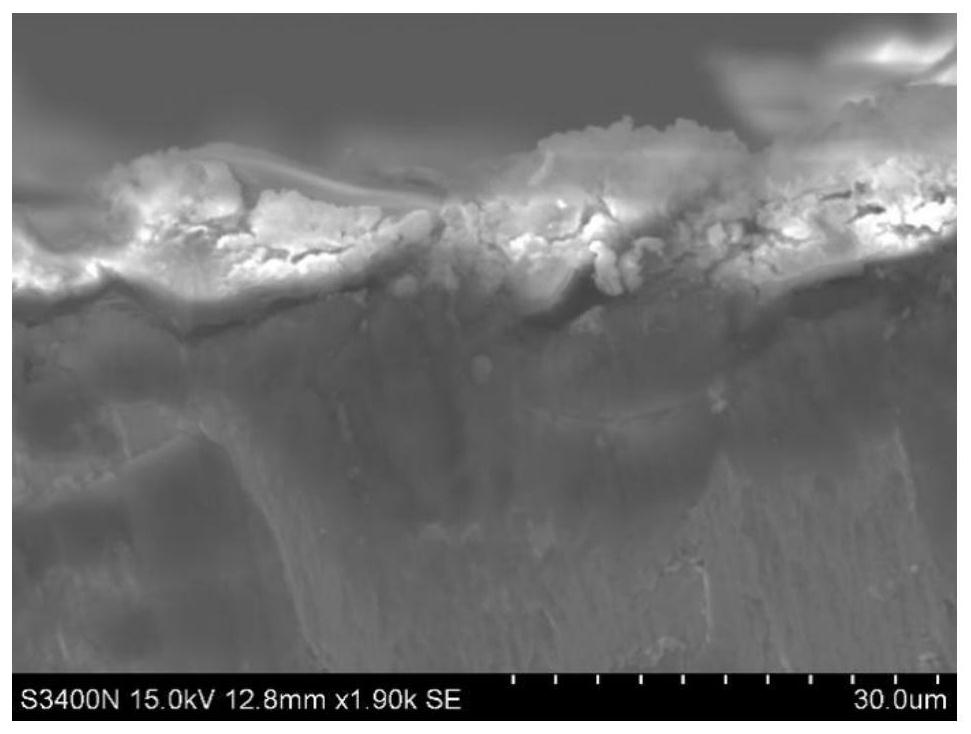

[0043] Figure 4 A scanning electron micrograph of the lithium negative electrode surface of the LIF film is included in Example 2. From image 3 It can be seen that the surface of the LIF film is flat, uniform and dense, and some granular projections are due to excessive growth of LIF.

Embodiment 3

[0045] 1. In the inert atmosphere of sealing conditions, 100 mg of difluoromethanesulfonyl chloride is dissolved in 50 mL of tetrahydrofuran and poured into the polytetrafluoroethylene reaction kettle, preheating at 55 ° C for 15 min;

[0046] 2. Under an inert atmosphere, a metal lithium compound compound compound is placed in the fluorinated agent obtained from S1, and the reaction is 2 h;

[0047] 3. After tetrahydrofuran with tetrahydrofuran, dried at 100 ° C for 1 h to prepare a lithium negative electrode of the LIF film.

[0048] The lithium negative electrode assembly of the obtained coated LIF film was subjected to a symmetrical battery, and the lithium negative electrode and commercial lithium negative electrode of the obtained LIF film were assembled into a metal lithium half cell. Figure 5 A scanning electron microscope photograph of the lithium negative surface of the LIF film is held in Example 3. From Figure 4 It can be seen that the LIF block particles are closely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com