Preparation method of hollow bowl-shaped carbon-based metal/selenium/oxygen co-doped composite material and lithium ion battery

A composite material and metal-based technology, which is applied in the preparation of hollow bowl-shaped carbon-based metal/selenium/oxygen co-doped composite materials, can solve the problems of high purchase price, environmental pollution, narrow application, etc., and achieve process repeatability High, simple synthesis process, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

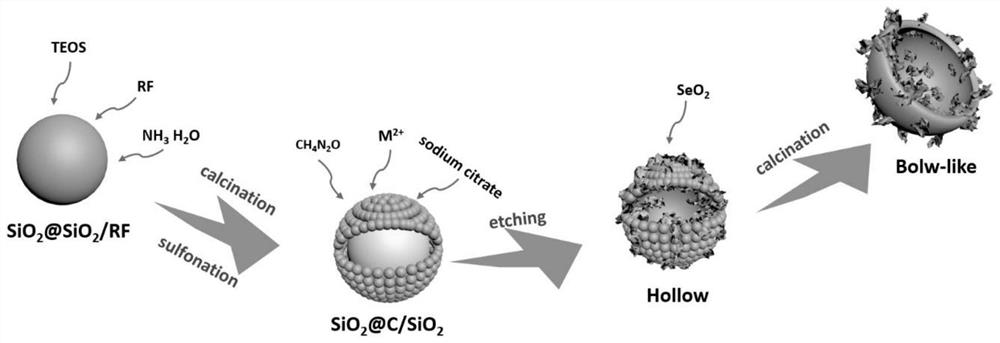

[0026] In view of the problems in the prior art that the hollow bowl-shaped carbon-based metal / selenium / oxygen co-doped composite material is difficult to prepare, the morphology is unstable, and the preparation process is not friendly to the environment, the application provides a hollow bowl-shaped carbon-based metal / selenium / oxygen co-doped composite material. A method for preparing a selenium / oxygen co-doped composite material, the preparation method is simple to operate, does not require special reagents or surfactants, and the prepared hollow bowl-shaped carbon-based metal / selenium / oxygen co-doped composite material has a stable shape, It has the advantages of hollow spherical structure with low density and large specific surface area. Specifically, the embodiment of the present invention discloses a method for preparing a hollow bowl-shaped carbon-based metal / selenium / oxygen co-doped composite material, including the following steps:

[0027] A) SiO 2 @Phenolic resin / S...

Embodiment 1

[0040] (1) Add 25mL TEOS to 515mL ethanol, 70mL water and 21mL ammonia water (25%wt%) solution, stir at room temperature for 20min, add resorcinol 2.8g and formaldehyde 4mL (37wt%), then stir at room temperature for 20h, Wash with distilled water and ethanol three times to collect the final solution, dry it in a vacuum oven at 60 °C for 12 h; then calcinate it in nitrogen at 800 °C for 2 h at a heating rate of 1 °C / min to obtain SiO 2 @C / SiO 2 ;

[0041] Disperse 1g of carbonized material in concentrated sulfuric acid at a mass ratio of 1:30, ultrasonicate at 30°C for 30min, collect by centrifugation with ethanol, and ultrasonically disperse 600mg of sulfonated carbon material into 2400mL, 4500mg of nickel nitrate hexahydrate, 8g of urea and 480mg of trisodium citrate Stir the solution at 80°C for 5 hours, cool to room temperature, collect the precipitate by centrifugation with ethanol, and dry at 60°C overnight;

[0042] (2) The material obtained in step (1) was etched away...

Embodiment 2

[0045] (1) Add 25mL TEOS to 515mL ethanol, 70mL water and 21mL ammonia water (25%wt%) solution, stir at room temperature for 20min, add resorcinol 2.8g and formaldehyde 4mL (37wt%), then stir at room temperature for 20h, Wash the final solution with distilled water and ethanol three times to collect the final solution, dry it in a vacuum oven at 60°C for 12h, and then calcinate it in nitrogen at 800°C for 2h at a heating rate of 1°C / min to obtain SiO 2 @C / SiO 2 ;

[0046] Disperse 1g of carbonized material in concentrated sulfuric acid at a mass ratio of 1:30, ultrasonicate at 30°C for 30min, and collect by centrifugation with ethanol; ultrasonically disperse 700mg of sulfonated carbon material into 2800mL of 5256mg of cobalt nitrate hexahydrate, 9.9g of urea and 576mg of tricitrate Stir in the sodium solution at 80°C for 5 hours, cool to room temperature, collect the precipitate by centrifugation with ethanol, and dry at 60°C overnight;

[0047] (2) The material obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com