A method for producing pigskin gelatin by acid method

A technology for pigskin gelatin and pigskin, which is applied in the preparation of animal glue or gelatin, can solve problems such as affecting the quality of finished gelatin, destroying the integrity of collagen subunits, etc. The effect of less wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

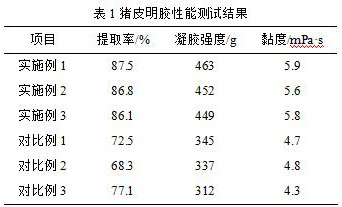

Examples

Embodiment 1

[0029] A kind of method that acid method produces pigskin gelatin, is made by following steps:

[0030] 1) Pretreatment: take fresh pigskin, clean it, depilate it, cut it into small pieces no larger than 4×4mm, add it to a sodium chloride solution with a mass fraction of 5%, soak it at 35°C for 4 hours, wash it with water to remove chlorine Sodium chloride is used to pretreat pigskin;

[0031] 2) Activation: Add the pretreated pigskin to the activation solution, soak it at 40°C for 3 hours, raise the temperature to 93°C, keep it for 4 minutes, cool it down to room temperature naturally, wash it with water, and control the moisture to obtain activated pigskin;

[0032] Said, the activation solution is prepared from the following raw materials in parts by weight: 3 parts of potassium chloride, 2 parts of sodium polyglutamate, 3 parts of citric acid, and 100 parts of water.

[0033] As mentioned, the weight ratio of pretreated pigskin and activation solution is 1:3.

[0034] 3)...

Embodiment 2

[0043] A kind of method that acid method produces pigskin gelatin, is made by following steps:

[0044] 1) Pretreatment: take fresh pigskin, clean it, depilate it, cut it into small pieces no larger than 4×4mm, add it to a sodium chloride solution with a mass fraction of 3%, soak it at 40°C for 5 hours, wash it with water to remove chlorine Sodium chloride is used to pretreat pigskin;

[0045] 2) Activation: Add the pretreated pigskin to the activation solution, soak it at 35°C for 2 hours, raise the temperature to 95°C, keep it for 3 minutes, cool it down to room temperature naturally, wash it with water, and control the moisture to obtain activated pigskin;

[0046] Said, the activation solution is prepared from the following raw materials in parts by weight: 5 parts of potassium chloride, 1 part of sodium polyglutamate, 4 parts of citric acid, and 100 parts of water.

[0047] As mentioned, the weight ratio of pretreated pigskin and activation solution is 1:2.

[0048] 3) ...

Embodiment 3

[0057] A kind of acid method is produced the method for pigskin gelatin, is made by following steps:

[0058] 1) Pretreatment: take fresh pigskin, clean it, depilate it, cut it into small pieces no larger than 4×4mm, add it to a sodium chloride solution with a mass fraction of 7%, soak it at 30°C for 3 hours, wash it with water to remove chlorine Sodium chloride is used to pretreat pigskin;

[0059] 2) Activation: Add the pretreated pigskin to the activation solution, soak it at 45°C for 2-4 hours, raise the temperature to 90-95°C, keep it for 3-5 minutes, cool it down to room temperature naturally, wash it with water, and dry it to get the activated pig Skin;

[0060] Said, the activation solution is prepared from the following raw materials in parts by weight: 1-5 parts of potassium chloride, 1-3 parts of sodium polyglutamate, 2-4 parts of citric acid, and 100 parts of water.

[0061] Said, the weight ratio of the pretreated pigskin and the activation solution is 1:2-4.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com