Harmless treatment and resource utilization method of alkali slag of soda ash produced by ammonia-soda method

A technology of ammonia-soda method and alkali slag, which is applied in the field of harmless treatment and resource utilization of alkali slag produced by ammonia-soda method, and can solve the comprehensive resource utilization of difficult dehydration and harmless treatment of alkali slag and unfavorable alkali slag , Alkali slag can not be used as a resource, etc., to achieve the effect of easy pulverization, no stickiness, good flocculation effect, and easy resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: Treatment of highly alkaline, high ammonia nitrogen, high salinity, high water content alkali slag

[0070] The alkali slag aimed at in this embodiment has the following characteristics: high alkalinity, high ammonia nitrogen, high salinity, high water content (pH>9, ammonia nitrogen content 64-97mg / L, water content 30-80%, chloride ion content 22-27% ), in addition, it also has the characteristics of strong colloid, high viscosity, more bound water, and strong hydrophilicity.

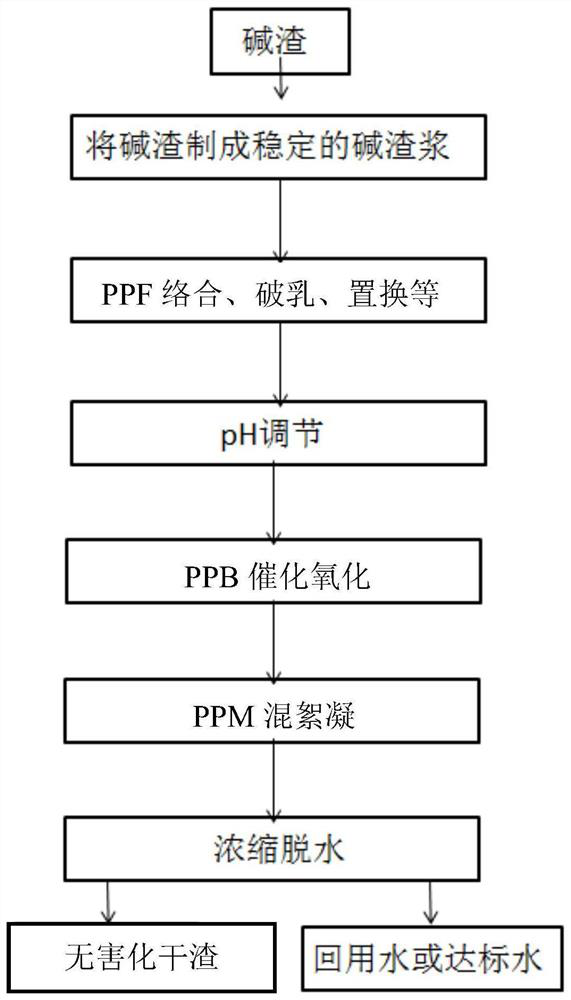

[0071] This embodiment adopts figure 1 The method shown is used for treatment, and the system includes a mixed concentration section, a physicochemical reaction section and a mechanical dehydration section connected in sequence.

[0072] The mixing and concentrating section includes a dissolving and mixing tank and a first concentrator connected in sequence.

[0073] The physical-chemical reaction section includes a physical-chemical reactor, a catalytic redox reactor, a second c...

experiment example 1

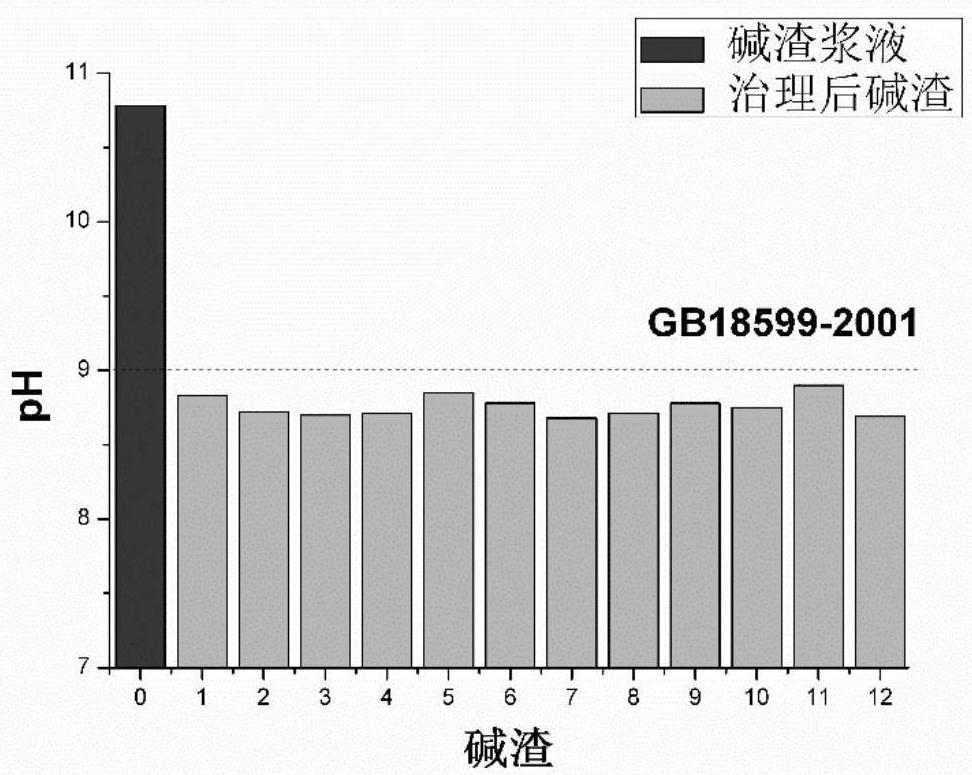

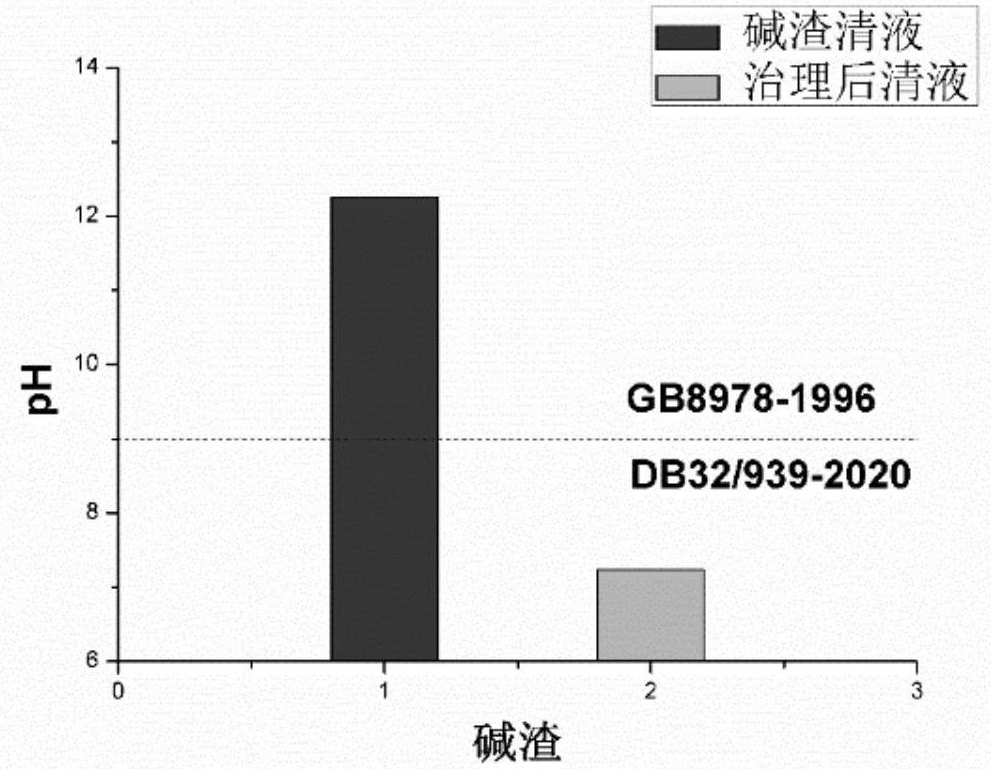

[0102] Component analysis after experimental example 1 alkali slag treatment of the present invention:

[0103] The soda slag in this experiment example is the soda slag produced by the ammonia-soda method soda plant, which mainly has the following characteristics: high alkalinity, high ammonia nitrogen, high salinity, and high water content. In addition, it also has strong colloidal properties, high viscosity, bound water Many, hydrophilic characteristics.

[0104] 1. Composition analysis of original alkali slag

[0105] According to relevant national standards and local standards of Jiangsu Province, after a comprehensive analysis of the production process of alkali slag, its main pollution sources are mainly concentrated in pH and ammonia nitrogen. For safety reasons, heavy metal pollution was also tested.

[0106] Laboratory tests show that the solid pH and ammonia nitrogen content in the alkali slag pool exceed the standard, which is the main control item. The details a...

experiment example 2

[0162] Experimental example 2: Evaluation of the properties of alkali slag after treatment as filling soil for engineering sites

[0163] According to the characteristics of alkali slag and the local environment and economic situation of resource utilization, it is planned to use the treated alkali slag as the filling soil of the project site for resource utilization. As a general engineering site fill, according to the standard specifications and construction experience, it should meet a certain bearing capacity, and its corrosion characteristics, freeze-thaw characteristics, reinforcement characteristics, hydrolysis and water softening and disintegration characteristics should be evaluated.

[0164] The specific test results are as follows:

[0165] 1. Carrying capacity

[0166] Alkali slag is used as backfill soil, and the characteristic value of bearing capacity after absorbing water and deliquescence saturation is not less than 80kPa.

[0167] For this reason, the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com