Metal lithium negative electrode for in-situ construction of multifunctional biomimetic membrane and preparation method of metal lithium negative electrode

A biomimetic membrane, multi-functional technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problem of safety performance and electrochemical cycle performance that cannot meet high energy density batteries, loss of active positive active materials, and surface blockage of metal lithium negative electrodes. and other problems, to achieve the effect of promoting uniform deposition, improving cycle stability, and reducing local current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

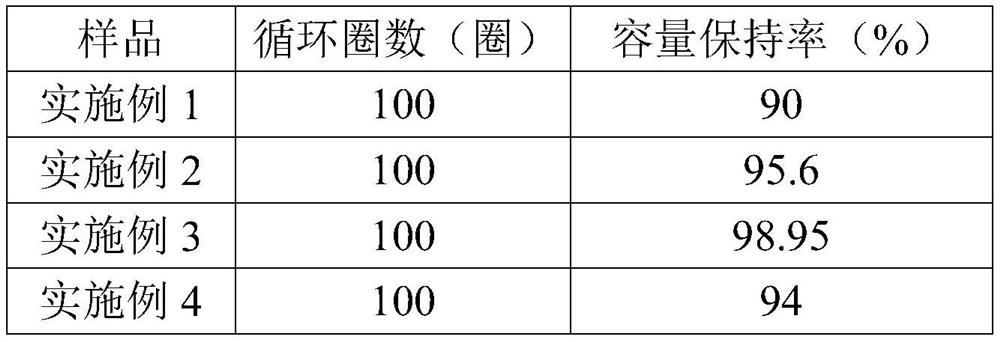

Embodiment 1

[0029] First, select straw as biomass material, and carbonize it under inert gas at 400°C for 3 hours to obtain porous biomass carbon; add concentrated sulfuric acid to introduce acidic active groups of sulfonic acid groups, filter, wash, and dry to obtain a mixture of biomass with sulfonic acid groups Carbon material; in the mixture of mixed carbon material and polyvinylidene fluoride resin film with a mass ratio of 7:3, add N-methylpyrrolidone corresponding to 20% of the resin film and stir to make it fully mixed. Then add a volatile non-corresponding solvent tetrahydrofuran, the content of which is 1%-50% relative to the mass of the solvent; then use wet spinning to carry out in-situ electrospinning of the mixture on the surface of metal lithium to obtain a biomimetic biomass with uniform structure Membrane, the spinning conditions are as follows: spinning temperature is 25°C, spinning voltage is 30kV, propulsion speed is 3μL / min, spinning distance is 10cm, moisture is contr...

Embodiment 2

[0031] First, choose succulents as biomass materials, and carbonize them under inert gas at 400°C for 3 hours to obtain porous biomass carbon; add concentrated sulfuric acid to introduce acidic active groups of sulfonic acid groups, filter, wash, and dry to obtain a mixture of biomass with sulfonic acid groups Carbon material; in the mixture of mixed carbon material and polyvinylidene fluoride resin film with a mass ratio of 7:3, add N-methylpyrrolidone corresponding to 20% of the resin film and stir to make it fully mixed. Then add a volatile non-corresponding solvent tetrahydrofuran, the content of which is 10% relative to the mass of the solvent; then use wet spinning to carry out in-situ electrospinning of the mixture on the surface of metal lithium to obtain a biomimetic membrane of biomass with uniform structure. The spinning conditions are as follows: the spinning temperature is 25°C, the spinning voltage is 30kV, the propulsion speed is 3μL / min, the spinning distance is...

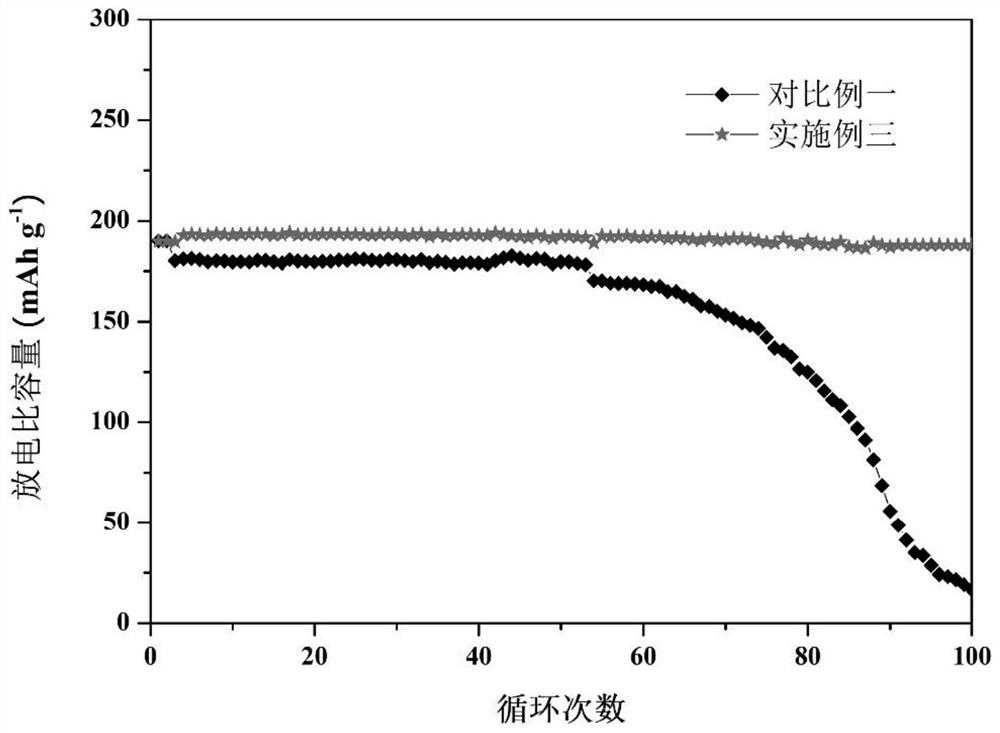

Embodiment 3

[0033]First, corncobs are selected as biomass material, and carbonized under inert gas at 400°C for 3 hours to obtain porous biomass carbon; adding concentrated sulfuric acid to introduce acidic active groups of sulfonic acid groups, suction filtration, washing, and drying to obtain biomass with sulfonic acid groups Mixed carbon material; in the mixture of mixed carbon material and polyvinylidene fluoride resin film with a mass ratio of 7:3, add N-methylpyrrolidone corresponding to 20% of the resin film and stir to make it fully mixed. Then add a volatile non-corresponding solvent tetrahydrofuran, the content of which is 20% relative to the mass of the solvent; then use wet spinning to carry out in-situ electrospinning of the mixture on the surface of metal lithium to obtain a biomimetic membrane of biomass with uniform structure. The spinning conditions are as follows: the spinning temperature is 25°C, the spinning voltage is 25kV, the propulsion speed is 3μL / min, the spinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com