Alkali metal negative electrode composite protective film and preparation method thereof, alkali metal negative electrode and alkali metal secondary battery

A secondary battery, alkali metal technology, used in secondary batteries, fuel cell-type half-cells, secondary battery-type half-cells, negative electrodes, etc., can solve problems such as corrosion, prevent dendrites and corrosion, Good barrier effect to prevent uncontrolled growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the alkali metal negative electrode composite protective film described in the above technical solution, comprising the following steps:

[0047] The fluorocarbon polymer is flatly spread on the surface of the alkali metal negative electrode, the in-situ reaction is carried out on the surface of the alkali metal negative electrode, and the composite protective film of the alkali metal negative electrode is obtained by growing on the surface of the alkali metal negative electrode.

[0048] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0049] In the present invention, the fluorocarbon polymer preferably includes one or more of polytetrafluoroethylene, polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene and ethylene-tetrafluoroethylene copolymer; when the When the fluorocarbon polymer is two or ...

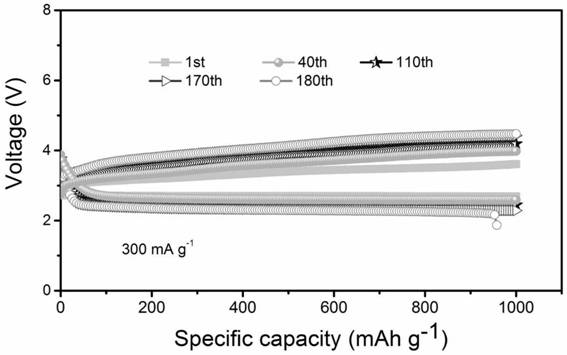

Embodiment 1

[0094] Provide positive electrode materials, the electrode material is Ru, the conductive material is carbon nanotubes, the binder is polyvinylidene fluoride, and the mass ratio of Ru, polyvinylidene fluoride and carbon nanotubes is 2:1:6;

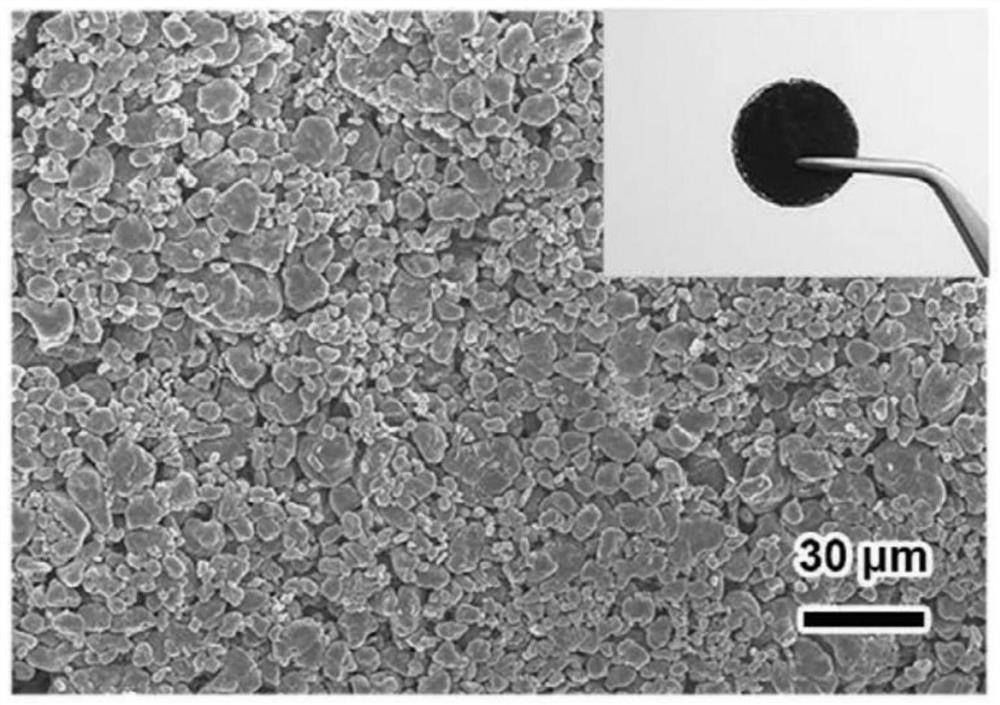

[0095] Spread 0.2 g of polytetrafluoroethylene on the surface of a lithium sheet (14 mm in diameter and 400 μm in thickness), react in situ at a temperature of 300 ° C for 5 min in an argon glove box, and then cool naturally to room temperature, and remove the remaining residue on the surface of the lithium sheet. The polytetrafluoroethylene is cleaned up to obtain an alkali metal negative electrode containing a composite protective film, and the thickness ratio of the composite protective film to the alkali metal is 1:20;

[0096] Use 0.2 mL of tetraethylene glycol dimethyl ether solution of lithium trifluoromethanesulfonate with a molar concentration of 1 mol / L as the electrolyte;

[0097] The glass fiber membrane is used as the diaphrag...

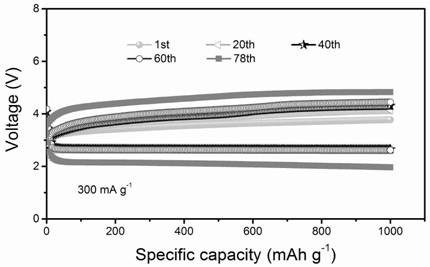

Embodiment 2

[0101] Provide positive electrode materials, the electrode material is Ru, the conductive material is carbon nanotubes, the binder is polyvinylidene fluoride, and the mass ratio of Ru, polyvinylidene fluoride and carbon nanotubes is 2:1:6;

[0102] Spread 0.2g of polyvinylidene fluoride on the surface of a lithium sheet (14mm in diameter and 400μm in thickness) in mass, react in situ at 300°C for 5min in an argon glove box, and then cool naturally to room temperature. The remaining polyvinylidene fluoride on the surface is cleaned to obtain an alkali metal negative electrode containing a composite protective film, and the thickness ratio of the composite protective film to the alkali metal is 1:20;

[0103] Use 0.2 mL of tetraethylene glycol dimethyl ether solution of lithium trifluoromethanesulfonate with a molar concentration of 1 mol / L as the electrolyte;

[0104] The glass fiber membrane is used as the diaphragm;

[0105] Oxygen as gas;

[0106] The alkali metal negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com