Polycrystalline silicon ingot and preparation method thereof

A technology of polycrystalline silicon ingots and polycrystalline silicon, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of multiple battery stalls, dispersion, and difficulties in industrialization, so as to facilitate mass production, improve conversion efficiency, The effect of reducing battery stalls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a kind of preparation method of polycrystalline silicon ingot, it is characterized in that, comprises the following steps:

[0032] a) Lay the seed crystal on the bottom of the crucible, and then cover the polycrystalline silicon material to obtain the packed silicon material; the seed crystal is single crystal silicon with a single crystal orientation;

[0033] b) Performing directional solidification growth, annealing and cooling sequentially on the loaded silicon material obtained in step a), to obtain polycrystalline silicon ingots.

[0034] In the invention, firstly, the seed crystal is laid on the bottom of the crucible, and then the polysilicon material is covered to obtain the loaded silicon material. In the present invention, there is no special limitation on the source of the crucible, and a commercially available common crucible well known to those skilled in the art can be used. In a preferred embodiment of the present inventi...

Embodiment 1

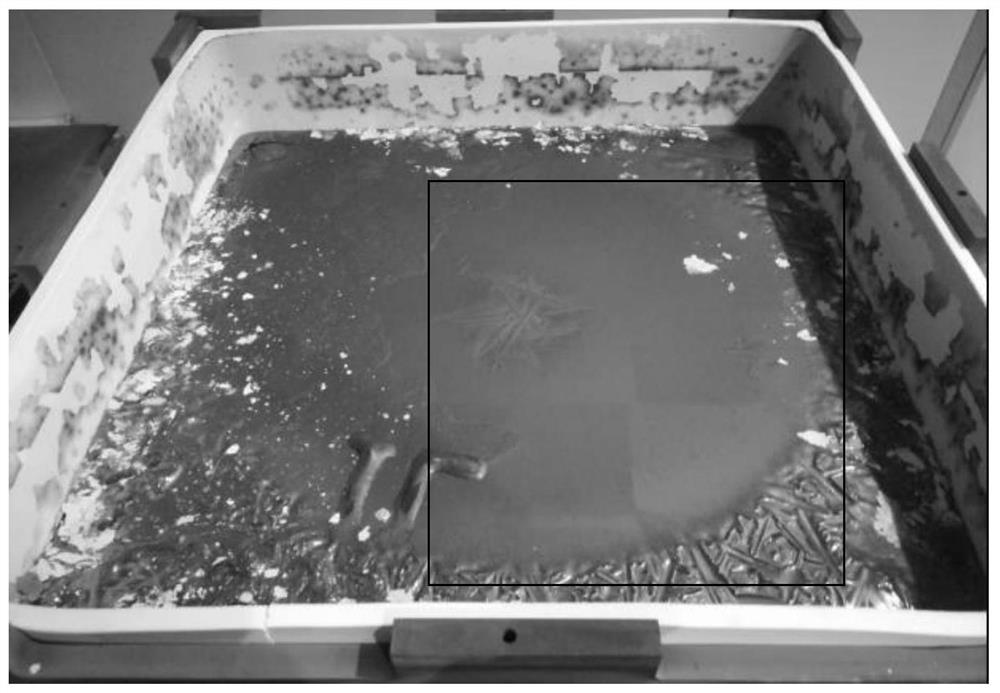

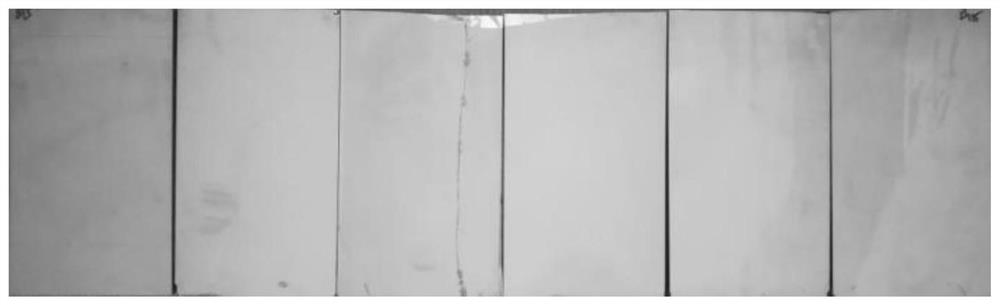

[0063] (1) Seed crystal laying and charging: Arrange the seed crystals on the release layer of the inner bottom of the crucible according to 6mm×6mm, and then put the prepared polysilicon material on the seed crystals to match the size, and put them in at the same time The master alloy is used for doping to obtain the loaded silicon material.

[0064] (2) Directional solidification growth: the crucible filled with silicon material is fitted with guard plates, and placed in a crystal growth furnace for directional solidification growth to obtain grown polysilicon;

[0065] The process of the directional solidification growth is specifically:

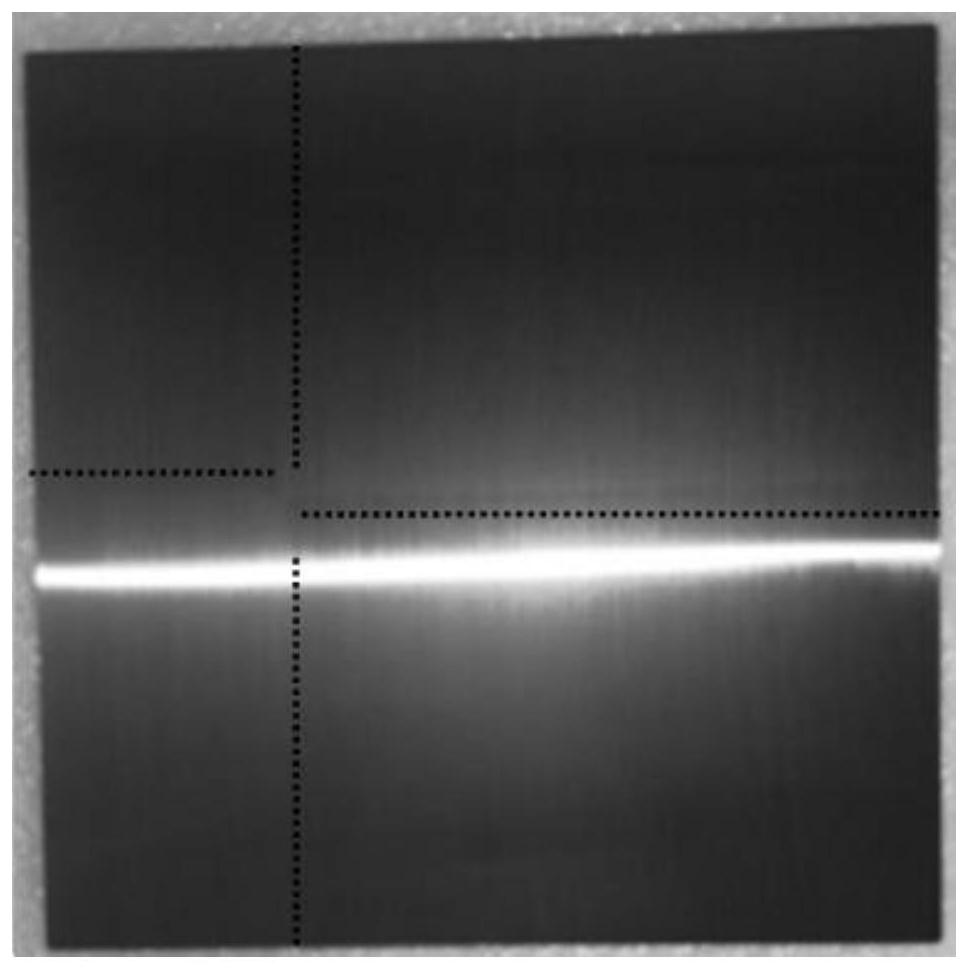

[0066] First, place the crucible filled with silicon material in the upper, middle and lower thermal fields and heat it until the temperature of the upper thermal field is 1150°C, the temperature of the middle thermal field is 1100°C, the temperature of the lower thermal field is 1100°C, and the heating time is 280min; then control The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com