Surface treatment method for 304-series high-grade panel stainless steel raw materials

A surface treatment, stainless steel technology, used in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of unsatisfactory roughness, pit-like defects, and inability to remove iron scales, and achieve uniformity between the operation side and the transmission side. , the effect of roughness reduction and high product quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

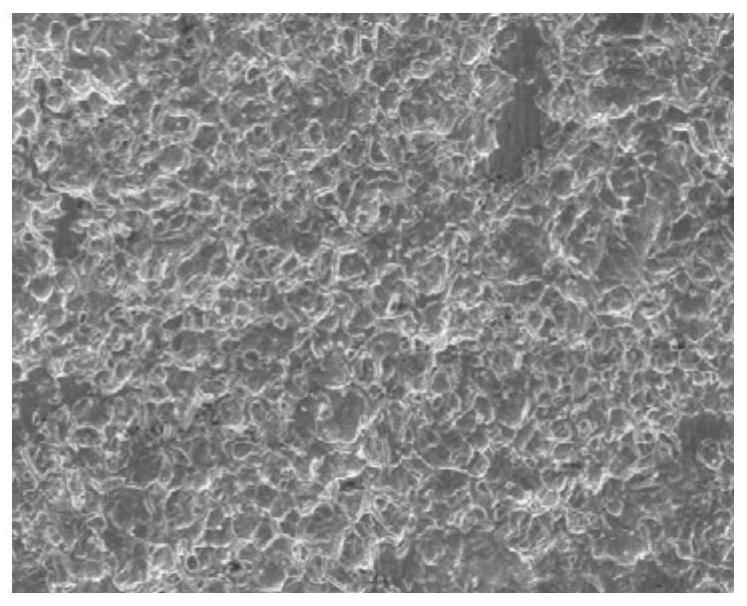

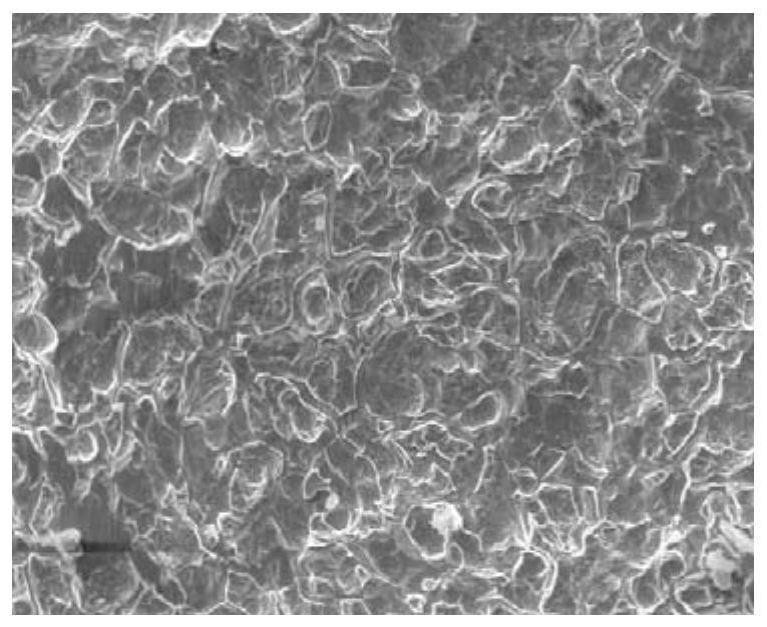

Image

Examples

Embodiment 1

[0062] The 304 strip steel raw materials that present embodiment adopts have following element composition (weight %):

[0063] C 0.08%, Si 1.00%, Mn 1.50%, P 0.040%, S 0.020%, Cr 19%, Ni 8.00%, and the rest are Fe and unavoidable impurities.

[0064] The thickness of the 304 strip steel raw material that present embodiment adopts is 3.5mm, and width is 1000mm.

[0065] This embodiment is specifically as follows:

[0066] (1) Annealing process:

[0067] The 304 hot-rolled black leather coils are annealed after being welded by a welding machine. Zone-12 furnace temperature control 1080 ℃.

[0068] (2) Scale-breaking shot blasting process:

[0069] The phosphorus-breaking process uses a large elongation to pass the line, and the test process uses 1.5% elongation. Adjust the shot blasting speed to 1750r / min before crossing the line. The current of the shot blasting machine is stable at 90A, and the speed of the shot blasting head is 1750r / min.

[0070] (3) Pickling process...

Embodiment 2

[0075] The 304 strip steel raw materials that present embodiment adopts have following element composition (weight %):

[0076] C 0.06%, Si 0.8%, Mn 2.00%, P 0.045%, S 0.020%, Cr 18%, Ni 10.50%, and the rest are Fe and unavoidable impurities.

[0077] The thickness of the 304 strip steel raw material that present embodiment adopts is 5.0mm, and width is 1250mm.

[0078] This embodiment is specifically as follows:

[0079] (1) Annealing process:

[0080] 304 hot-rolled black leather coils are annealed after being welded by a welding machine. The low-temperature annealing process is adopted. The line-passing speed TV is set at 130mm×m / min. Zone-12 furnace temperature control 1065 ℃.

[0081] (2) Scale-breaking shot blasting process:

[0082] The phosphorus-breaking process uses a large elongation to pass the line, and the test process uses 1.8% elongation. Adjust the shot blasting speed to 1720r / min before crossing the line. The current of the shot blasting machine is stab...

Embodiment 3

[0087] The 304 strip steel raw materials that present embodiment adopts have following element composition (weight %):

[0088] C 0.07%, Si 0.%, Mn 1.90%, P 0.035%, S 0.025%, Cr 20.00%, Ni 10.00%, and the rest are Fe and unavoidable impurities.

[0089] The thickness of the 304 strip steel raw material that present embodiment adopts is 4.0mm, and width is 1150mm.

[0090] This embodiment is specifically as follows:

[0091] (1) Annealing process:

[0092] The 304 hot-rolled black leather coils are annealed after being welded by a welding machine. The low-temperature annealing process is adopted. The line-passing speed TV is set at 130mm×m / min. Zone-12 furnace temperature control 1095 ℃.

[0093] (2) Scale-breaking shot blasting process:

[0094] The phosphorus-breaking process uses a large elongation to pass the line, and the test process uses 1.8% elongation. Adjust the shot blasting speed to 1780r / min before crossing the line. The current of the shot blasting machine i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com