A kind of production process of bovine collagen peptide

A production process and collagen peptide technology, which is applied in the field of protein peptide preparation and can solve the problems of easy precipitation of solutions and poor water solubility of solid collagen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

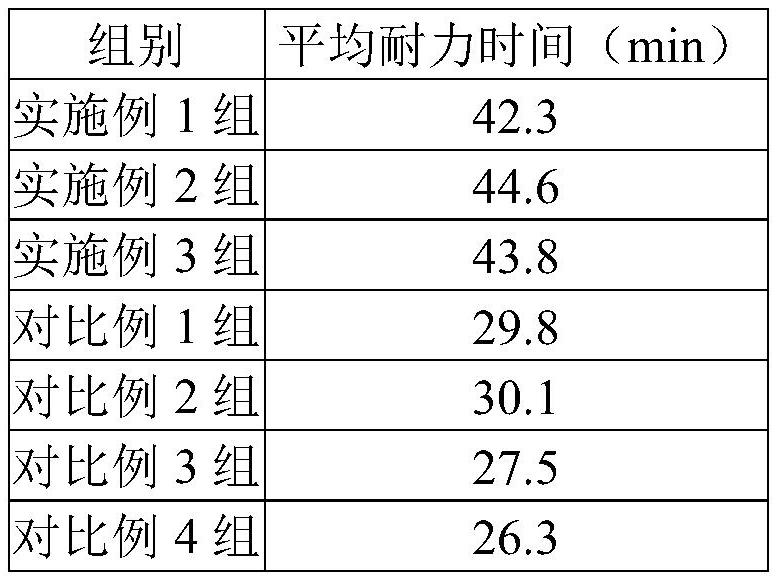

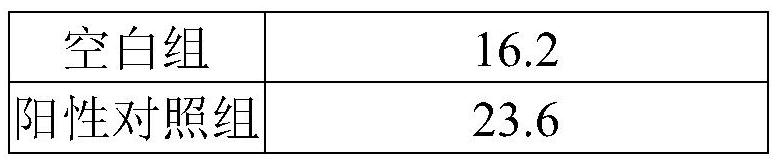

[0031] Embodiment 1 A kind of production technology of bovine collagen peptide

[0032] The production technology of described bovine collagen peptide, comprises the steps:

[0033] S1. Pretreatment of raw materials: select freshly washed bovine bones, add 10 times the mass of sodium hydroxide solution with a concentration of 0.05 mol / L and soak for 3 hours, then use a bone crusher to crush the bones to 1 cm in size, and put them into steaming Add water that is 8 times the weight of beef bones into the tank, and cook at 120°C for 1.5 hours to obtain a cooking liquid;

[0034] S2. Separation of oil and water: performing oil-water separation on the cooking liquid described in step S1 to remove grease to obtain a crude collagen solution;

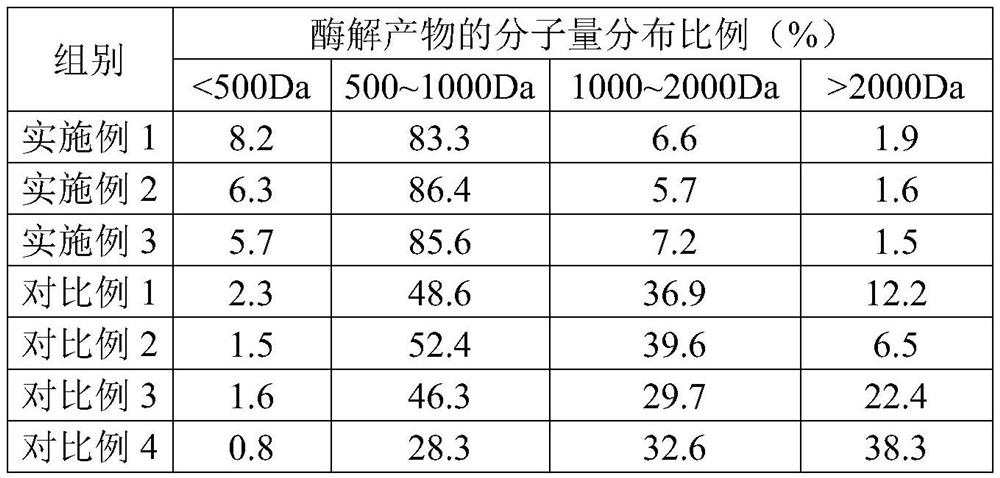

[0035] S3, enzymatic hydrolysis: add compound protease to the crude collagen solution obtained in step S2 and carry out an enzymolysis at a temperature of 55° C., the enzymolysis time is 1 h, and the compound protease is bromelain and pepsin i...

Embodiment 2

[0040] Embodiment 2 A kind of production technology of bovine bone collagen peptide

[0041] The production technology of described bovine collagen peptide, comprises the steps:

[0042] S1. Raw material pretreatment: select freshly washed bovine bones, add 15 times the mass of sodium hydroxide solution with a concentration of 0.01mol / L and soak for 4 hours, then crush them to 1.5cm bone pieces with a bone crusher, put them in Add water 10 times the weight of beef bones into the cooking tank, and cook at 130°C for 2.5 hours to obtain a cooking liquid;

[0043] S2. Separation of oil and water: performing oil-water separation on the cooking liquid described in step S1 to remove grease to obtain a crude collagen solution;

[0044] S3. Enzymolysis: add a compound protease to the crude collagen solution obtained in step S2 to perform an enzymolysis at a temperature of 58° C., and the enzymolysis time is 1.5 h. The compound protease is subtilisin, pepsin and trypsin According to t...

Embodiment 3

[0049] Embodiment 3 A kind of production technology of bovine bone collagen peptide

[0050] The production technology of described bovine collagen peptide, comprises the steps:

[0051] S1. Raw material pretreatment: select freshly washed bovine bones, add 20 times the mass of sodium hydroxide solution with a concentration of 0.15 mol / L and soak for 6 hours, then use a bone crusher to crush the bones to 2 cm, and put them into steaming Add water 12 times the weight of beef bones into the tank, and cook at 135°C for 3 hours to obtain a cooking liquid;

[0052] S2. Separation of oil and water: performing oil-water separation on the cooking liquid described in step S1 to remove grease to obtain a crude collagen solution;

[0053] S3. Enzymolysis: add a compound protease to the crude collagen solution obtained in step S2 to carry out an enzymolysis at a temperature of 60° C., and the enzymolysis time is 2 hours. The compound protease is subtilisin, bromelain, pepsin, One or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com