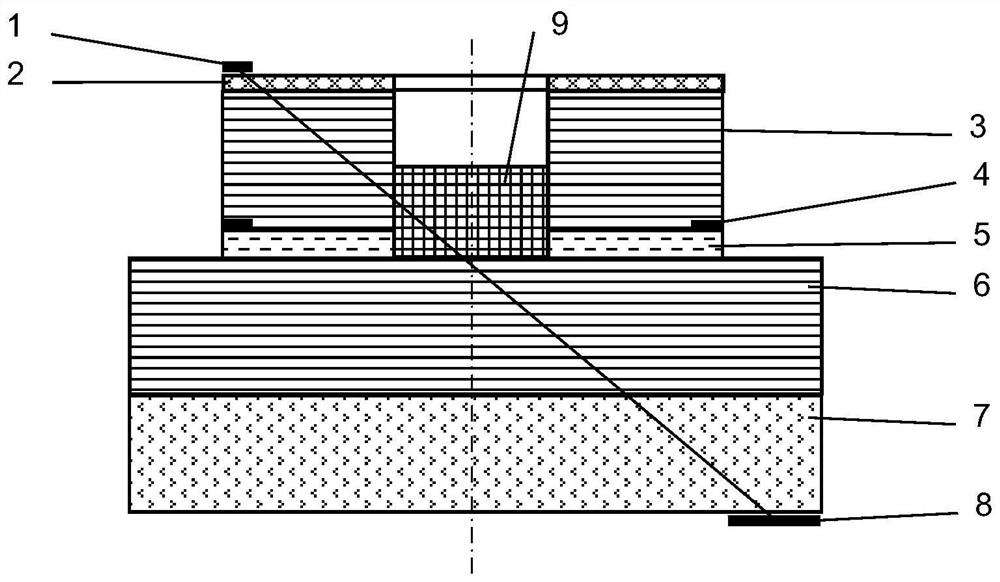

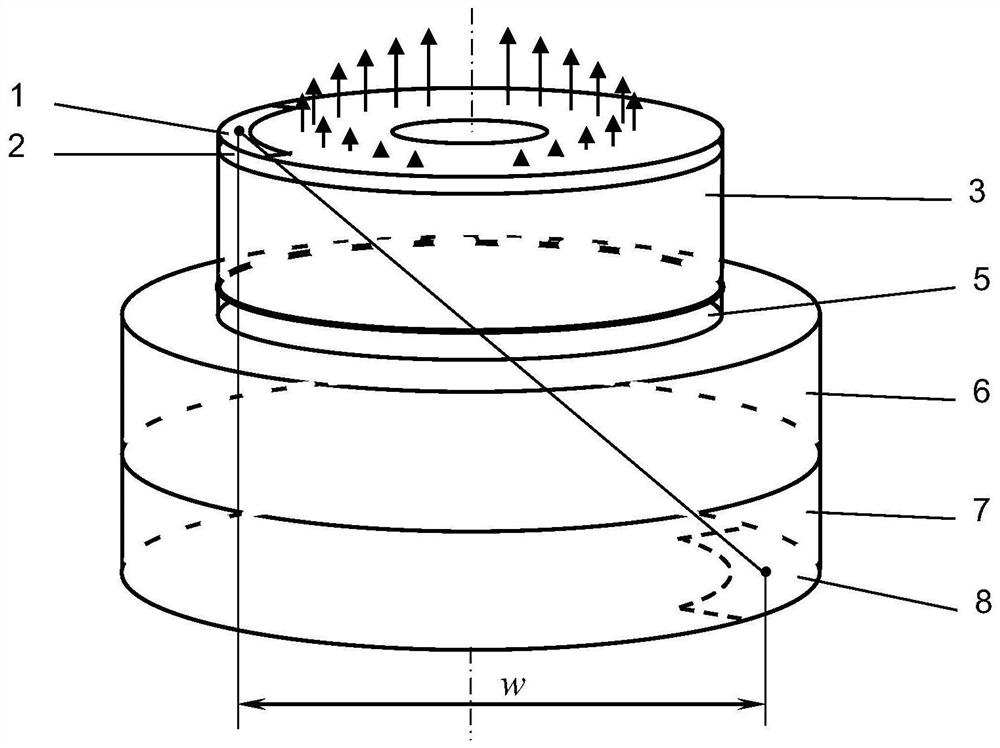

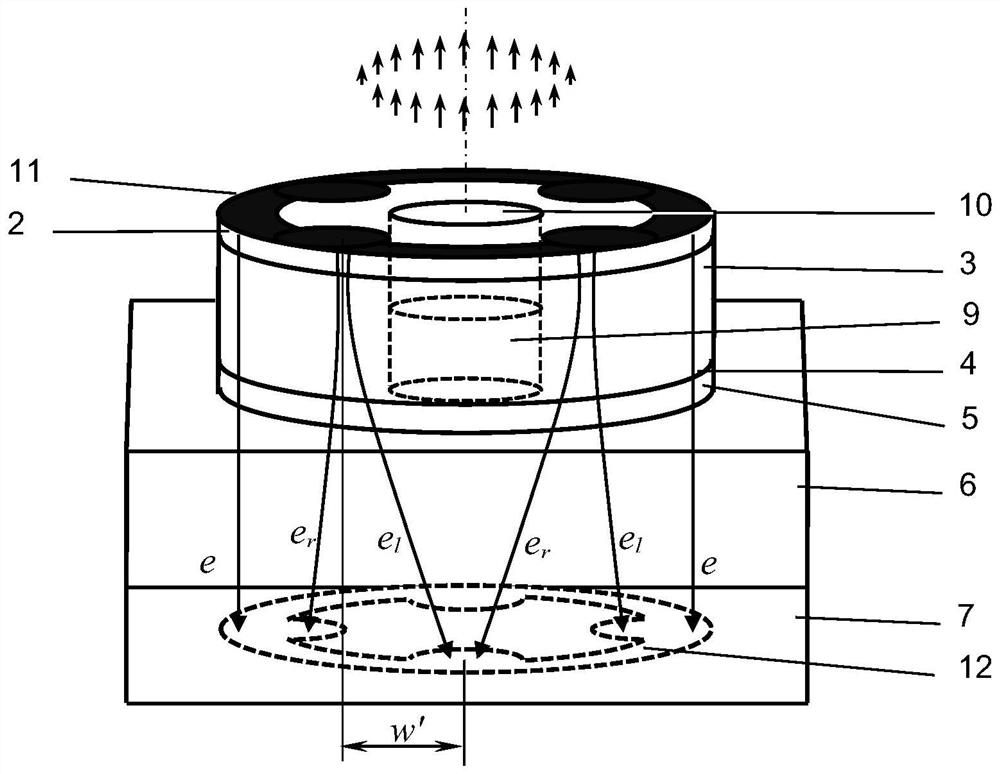

Vertical cavity surface emitting semiconductor laser with upper and lower electrodes arranged in staggered manner

A technology of vertical cavity surface emission and lasers, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of long current path, reduced luminous efficiency of devices, large series resistance, etc., and achieves increased orbital angular momentum and luminous efficiency. The effect of increasing and decreasing the series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the vertical cavity surface emitting semiconductor laser with disclination arrangement of the upper and lower electrodes of the present invention, the number of the extensions 14 of the disclination upper electrode 11 and the disclination lower electrode 12 is 3 or 4, and the disclination upper electrode 11 or the disclination The specific structure of the lower electrode 12 includes the following four types: 4 extensions 14 are located on the inner circle of the main body 13, such as Figure 4 Shown; 3 expansion parts 14 are located on the outer circle of main body part 13, as Figure 5 Shown; 3 expansion parts 14 are located on the inner circle of the main body part 13, as Figure 6 Shown; 4 expansion parts 14 are located on the outer circle of main body part 13, as Figure 7 shown. When the number of extensions 14 is 4, they are distributed at intervals of 1 / 2π radian, and the disclination upper electrode 11 and the disclination lower electrode 12 are disclinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com