Composite solid electrolyte, preparation method thereof and lithium storage battery

A solid electrolyte, electrolyte membrane technology, applied in the direction of electrolyte immobilization/gelation, secondary batteries, circuits, etc., can solve the problem of reducing the cycle life and cycle performance of lithium batteries, limited improvement of battery short-circuit protection, and poor metal lithium deposition. Uniform aggravation and other problems, to achieve the effect of light weight, prevention of lithium dendrite puncture, and strong mechanical integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the composite solid electrolyte includes the following steps:

[0051] S1: Electron beam thermal deposition system is used to plate lithium onto the surface of the lithium source carrier film in vacuum, forming a thin lithium layer on the surface of the lithium source carrier film. The lithium source carrier film can be determined according to the situation, here is copper foil;

[0052] S2: The electrolyte membrane layer on the negative electrode side is made of PEO solid electrolyte, and one side of the electrolyte membrane layer on the negative electrode side is pre-coated with an infiltration solution, which is one of tetrahydrofuran, ethylene glycol dimethyl ether (DME), and acetonitrile (ACN). Lay the side of the lithium source carrier film with the lithium thin layer and the side of the electrolyte film layer on the negative electrode side coated with the immersion solution, heat and press the two rolls, and the pressure on the roll is 0....

Embodiment 1-6

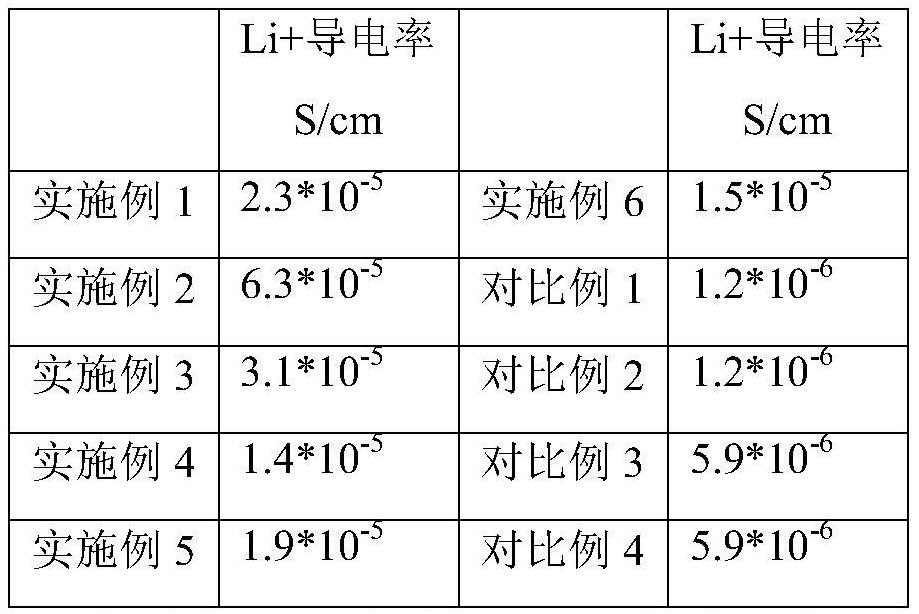

[0057] The composite solid electrolyte was prepared according to the above preparation method, and Examples 1-6 were obtained, and the specific parameters of Examples 1-6 are shown in Table 1.

[0058] Table 1. The concrete parameter table of embodiment 1-6

[0059] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Electrolyte layer thickness on the negative electrode side / μm 6 10 8 10 6 5 Electrolyte layer thickness on positive electrode side / μm 4 10 10 9 6.5 5 Thickness of ion dispersion layer / μm 2 5 3 0.8 1 0.5 Roll pressure / kgf·cm -2

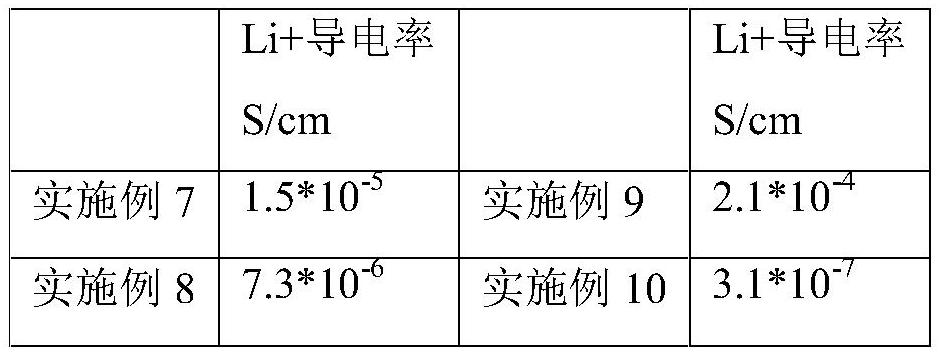

Embodiment 7

[0093] A composite solid electrolyte, based on the basis of Example 1, the difference is that the electrolyte membrane layer on the positive electrode side is a PEO solid electrolyte membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com