Amantadine hydrochloride impurity removal method

A technology for amantadine hydrochloride and amantadine, which is applied in the preparation of amino compounds from amines, purification/separation of amino compounds, and organic chemistry, etc. Synthesis process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

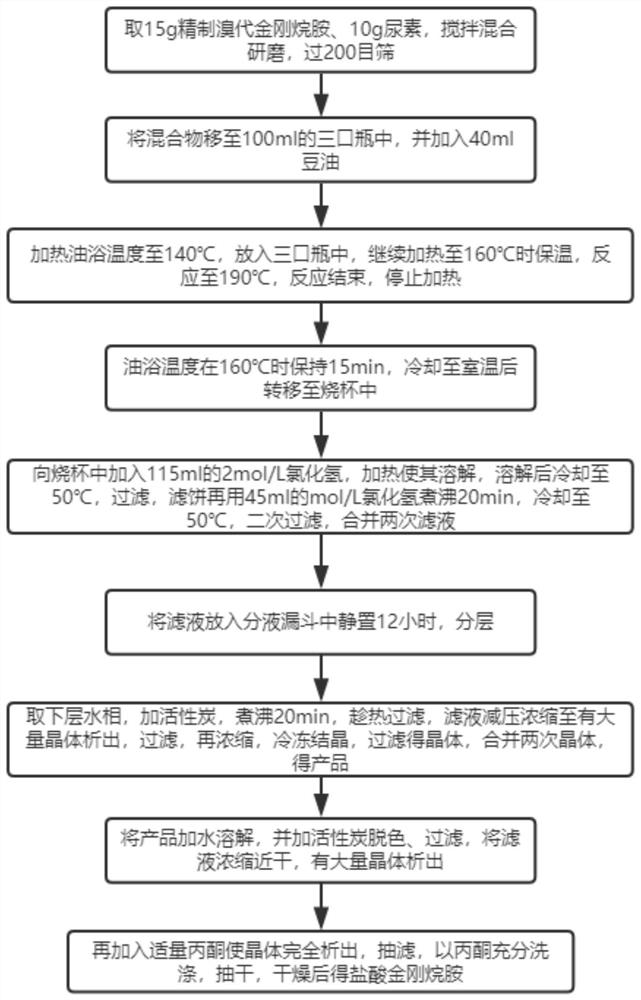

[0036] A method for removing impurities of amantadine hydrochloride, such as figure 1 shown, including the following steps:

[0037] S1: Take 15g of refined amantadine bromide and 10g of urea, stir, mix and grind, and pass through a 200-mesh sieve;

[0038] S2: Move the mixture to a 100ml three-necked bottle, and add 40ml of soybean oil;

[0039] S3: Heat the temperature of the oil bath to 140°C, put it into a three-neck bottle, continue heating to 160°C, keep it warm, react to 190°C, stop the heating when the reaction is over;

[0040] S4: Keep the temperature of the oil bath at 160°C for 15 minutes, transfer to a beaker after cooling to room temperature;

[0041] S5: Add 115ml of 2mol / L hydrogen chloride into the beaker, heat to dissolve, cool to 50°C after dissolving, filter, boil the filter cake with 45ml of mol / L hydrogen chloride for 20min, cool to 50°C, filter twice, and combine twice the filtrate;

[0042] S6: Put the filtrate into a separatory funnel and let it st...

Embodiment 2

[0058] A method for removing impurities of amantadine hydrochloride, such as figure 1 shown, including the following steps:

[0059] S1: Take 15g of refined amantadine bromide and 10g of urea, stir, mix and grind, and pass through a 200-mesh sieve;

[0060] S2: Move the mixture to a 100ml three-necked bottle, and add 40ml of soybean oil;

[0061] S3: Heat the temperature of the oil bath to 140°C, put it into a three-neck bottle, continue heating to 160°C, keep it warm, react to 190°C, stop the heating when the reaction is over;

[0062] S4: Keep the temperature of the oil bath at 160°C for 15 minutes, transfer to a beaker after cooling to room temperature;

[0063] S5: Add 115ml of 2mol / L hydrogen chloride to the beaker, heat to dissolve, cool to 50°C after dissolving, filter, boil the filter cake with 45ml of mol / L hydrogen chloride for 20min, cool to 50°C, filter twice, and combine twice the filtrate;

[0064] S6: Put the filtrate into a separatory funnel and let it stan...

Embodiment 3

[0079] A method for removing impurities of amantadine hydrochloride, such as figure 1 shown, including the following steps:

[0080] S1: Take 15g of refined amantadine bromide and 10g of urea, stir, mix and grind, and pass through a 200-mesh sieve;

[0081] S2: Move the mixture to a 100ml three-necked bottle, and add 40ml of soybean oil;

[0082] S3: Heat the temperature of the oil bath to 140°C, put it into a three-neck bottle, continue heating to 160°C, keep it warm, react to 190°C, stop the heating when the reaction is over;

[0083] S4: Keep the temperature of the oil bath at 160°C for 15 minutes, transfer to a beaker after cooling to room temperature;

[0084] S5: Add 115ml of 2mol / L hydrogen chloride to the beaker, heat to dissolve, cool to 50°C after dissolving, filter, boil the filter cake with 45ml of mol / L hydrogen chloride for 20min, cool to 50°C, filter twice, and combine twice the filtrate;

[0085] S6: Put the filtrate into a separatory funnel and let it stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com