Sewage treatment flocculant embedded with microorganisms and preparation method of sewage treatment flocculant

A microbial flocculant and sewage treatment technology, applied in biological water/sewage treatment, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problem of low efficiency of reducing heavy metals, ineffective removal of heavy metal ions, functional group Low content and other problems, to achieve the effect of protecting stability, improving stability and enhancing flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

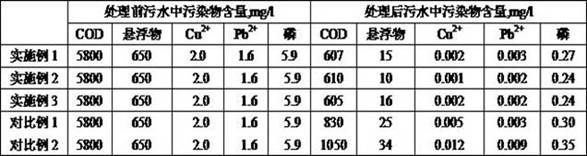

Examples

Embodiment 1

[0026] Raw material preparation: 65 parts of microbial flocculant and 25 parts of polymer flocculant.

[0027] 20 parts of Monascus and 40 parts of Bacillus licheniformis in the microbial flocculant.

[0028] The main raw materials of the polymer flocculant are 35 parts of ferric oxide, 60 parts of hydroxyl-terminated polycaprolactone, and 8-15 parts of polyaluminum chloride.

[0029] The fermentation medium mainly includes the following components: glucose 8.55g / L, yeast powder 1.53g / L, sodium chloride 5.05g / L, MgSO 4 ·7H 2 O 1.07g / L, potassium dihydrogen phosphate 15.83g / L.

[0030] A method for preparing a sewage treatment flocculant for embedding microorganisms, characterized in that it comprises the following steps;

[0031] (1) Preparation of microbial flocculant: take Monascus and Bacillus licheniformis strains and place them in the fermentation culture medium at a temperature of 37°C, ferment for 40 hours, centrifuge for 8 minutes, separate the liquid phase, and add...

Embodiment 2

[0036] Raw material preparation: 70 parts of microbial flocculant and 28 parts of polymer flocculant.

[0037]20 parts of Monascus and 40 parts of Bacillus licheniformis in the microbial flocculant.

[0038] The main raw materials of the polymer flocculant are 41 parts of ferric oxide, 63 parts of hydroxyl-terminated polycaprolactone, and 11 parts of polyaluminum chloride.

[0039] The fermentation medium mainly includes the following components: glucose 8.55g / L, yeast powder 1.53g / L, sodium chloride 5.05g / L, MgSO 4 ·7H 2 O 1.07g / L, potassium dihydrogen phosphate 15.83g / L.

[0040] A method for preparing a sewage treatment flocculant for embedding microorganisms, characterized in that it comprises the following steps;

[0041] (1) Preparation of microbial flocculant: take Monascus and Bacillus licheniformis strains and put them in the fermentation culture medium at a temperature of 42°C, ferment for 45 hours, centrifuge for 9 minutes, separate the liquid phase, and add 2 ti...

Embodiment 3

[0046] Raw material preparation: 75 parts of microbial flocculant and 35 parts of polymer flocculant.

[0047] 20 parts of Monascus and 40 parts of Bacillus licheniformis in the microbial flocculant.

[0048] The main raw materials of the polymer flocculant are 45 parts of ferric oxide, 70 parts of hydroxyl-terminated polycaprolactone, and 15 parts of polyaluminum chloride.

[0049] The fermentation medium mainly includes the following components: glucose 8.55g / L, yeast powder 1.53g / L, sodium chloride 5.05g / L, MgSO 4 ·7H 2 O 1.07g / L, potassium dihydrogen phosphate 15.83g / L.

[0050] A method for preparing a sewage treatment flocculant for embedding microorganisms, characterized in that it comprises the following steps;

[0051] (1) Preparation of microbial flocculant: take Monascus and Bacillus licheniformis strains and place them in the fermentation medium at a temperature of 45°C, ferment for 60 hours, centrifuge for 10 minutes, separate the liquid phase, and add 2 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com