High-temperature-resistant protective film, preparation process thereof and ITO conductive film

A technology of high temperature resistant protective film and preparation process, which is applied in the field of conductive film, can solve the problems of protective film residual glue granularity, ITO conductive film warping, and unqualified finished product quality, so as to achieve good product performance, improve process yield, The effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation process for a high temperature resistant protective film, comprising the steps of:

[0027] Step 1. Unwind and spread out the protective film substrate layer. The thickness of the protective film substrate layer is 23um-188um. The high temperature test is 150℃*1h*3 times, each time standing for more than 30min, and the haze changes △H ≤3%;

[0028] Step 2. Apply a layer of adhesive layer on the protective film substrate layer by coating methods such as scraper, slit, and gravure. The adhesive layer is doped with 2-8wt% hexahydrophthalic acid dishrinkle Glyceride or acrylic adhesive layer doped with 2-8wt% diglycidyl tetrahydrophthalate;

[0029] Step 3. Dry the protective film substrate layer coated with the adhesive layer in a 30m long drying tunnel at a speed of 15-25m / min. The 30m drying tunnel is divided into 5m*6 sections, and the 1-6 section oven Temperature step setting, respectively 40-50°C, 60-70°C, 100-110°C, 125-130°C, 125-130°C, 100-110°C, th...

Embodiment 1

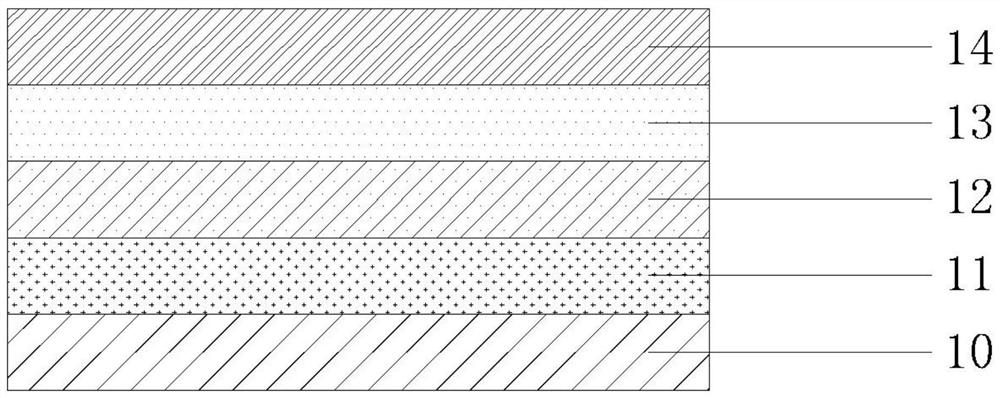

[0035] A kind of ITO conductive film, comprises the thick PET protective film substrate layer 10 of 75um, 15um thick doped with 5wt% hexahydrophthalate diglycidyl ester acrylic adhesive layer 11, HC layer 12, PET conductive Film substrate layer 13, ITO layer 14. This kind of ITO conductive film with high temperature resistant protective film is subjected to 150℃*1h*3 times, and after standing for 30 minutes each time, the thermal shrinkage rate TD1 and MD1 match the thermal shrinkage rate of ITO conductive film TD2 and MD2 to be 0.01%. The peel force on the HC surface is 15g / 25mm, and the dyne value on the HC surface is 36dyn. At this time, the high temperature resistant protective film for ITO has better flatness and no adhesive residue after peeling off.

Embodiment 2

[0037] A kind of ITO conductive film, comprising 125um thick COP protective film substrate layer 10, 25um thick doped with 8wt% tetrahydrophthalate diglycidyl ester acrylic adhesive layer 11, HC layer 12, COP conductive Film substrate layer 13, ITO layer 14. This kind of ITO conductive film with high temperature resistant protective film is subjected to 150℃*1h*3 times, and after standing for 30 minutes each time, the thermal shrinkage rate TD1, MD1 matches the thermal shrinkage rate of ITO conductive film TD2, MD2 is 0.06%, The peel force on the HC surface is 21g / 25mm, and the dyne value on the HC surface is 36dyn. At this time, the high temperature resistant protective film for ITO has better flatness and no adhesive residue after peeling off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com