Water-based high-temperature-resistant epoxy resin and preparation method thereof

An epoxy resin and high-temperature-resistant technology, applied in the direction of organic chemistry, can solve the problems of the final cured product’s comprehensive performance, affect the uniformity of curing, and cumbersome preparation steps, so as to improve the operability of construction and facilitate industrial production and preparation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Preferably, the preparation method of diepoxy compound of the present invention comprises the following steps:

[0064] Mix bismaleimide, solvent 1, and oxidation catalyst, add the oxidant solution dropwise at 10-40°C for 1-3 hours, then react for 10-30 hours, wash and dry to obtain the diepoxide .

[0065] The present invention does not specifically limit to solvent one, can enumerate have, water, ethyl acetate, butyl acetate, toluene, xylene, methylene chloride, acetone, N,N-dimethylformamide, N-methylpyrrolidone .

[0066] The present invention does not specifically limit to oxidation catalyst, can enumerate have, phosphotungstic heteropolyacid H 3 PW 12 o 40 , phosphotungstic acid H 6 P 2 W 18 o 64 , Methyl rhenium trioxide, O 2 , In one embodiment, the oxidation catalyst of the present invention accounts for 0.05-3 wt% of the weight of bismaleimide.

[0067] The present invention does not specifically limit to oxidizing agent, can enumerate have, hydrogen...

Embodiment 1

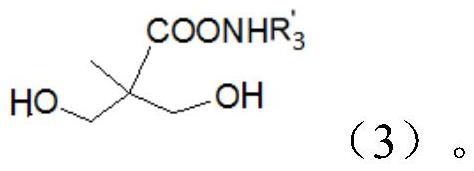

[0087] This example provides a kind of epoxy resin, the structural formula of described high temperature resistant epoxy resin is R is R' is an ethyl group, and n is 0.08.

[0088] This example also provides the preparation method of epoxy resin as above, including:

[0089] S1. in the 500ml four-necked flask that thermometer and agitator and reflux condenser are equipped with, add 179g bismaleimide structural formula is After 72g of toluene and 1.8g of catalyst H3PW12O40 were fully stirred and dissolved evenly, 0.9g of oxidant m-chloroperoxybenzoic acid solution diluted with 17.2g of toluene was added dropwise at 30°C, and the addition was completed after 2 hours. The oxidation reaction time was 20 hours, and sodium bicarbonate aqueous solution was added in sequence Wash with saturated brine, and remove the solvent by distillation under reduced pressure to obtain the product diepoxide

[0090] S2. Add diepoxides in a four-necked flask equipped with a thermometer and a...

Embodiment 2

[0092] This example provides a kind of epoxy resin, the structural formula of described high temperature resistant epoxy resin is R is R' is an ethyl group, and n is 0.054.

[0093] This example also provides the preparation method of epoxy resin as above, including:

[0094] S1. in the 500ml four-necked flask that thermometer and stirrer and reflux condenser are equipped with, add 134g bismaleimide structural formula is After 54g of toluene and 2g of the catalyst methyl rhenium trioxide are fully stirred and dissolved evenly, 0.5g of the oxidant tert-butyl peroxide solution diluted with 13g of toluene is added dropwise at 25°C, and the addition is completed after 2 hours. The oxidation reaction time is 25 hours, and hydrogen carbonate is added in turn. Sodium aqueous solution and saturated brine washing, decompression distillation removes solvent, obtains product diepoxide

[0095] S2. Add diepoxides to a four-necked flask equipped with a thermometer and a stirrer, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com