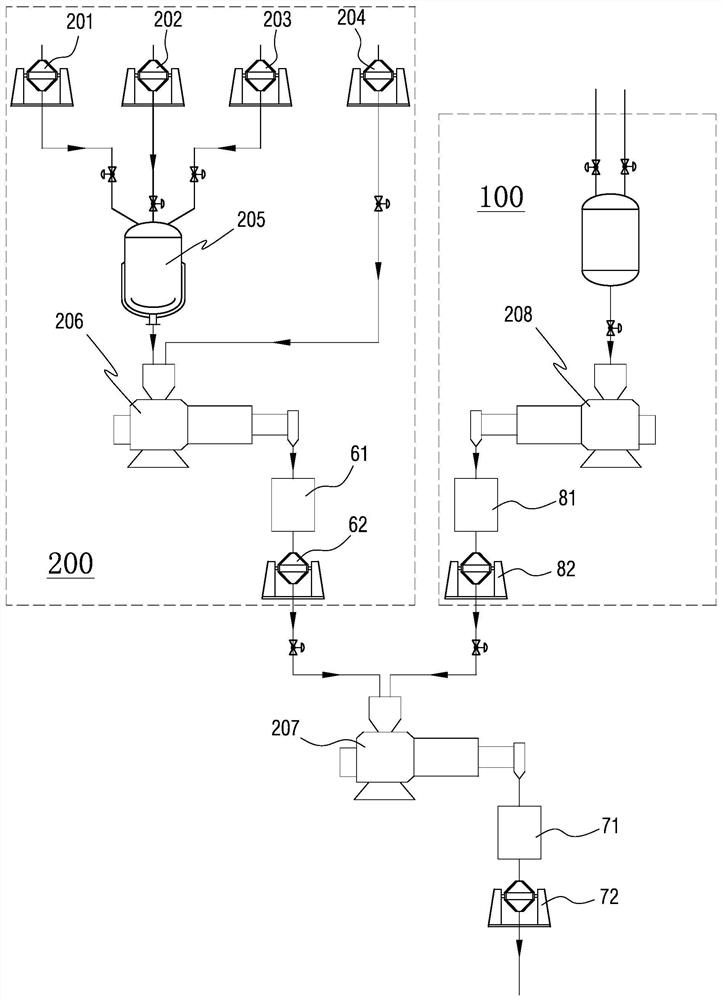

Production system for polyester master batch for preparing polyester products

A production system and technology of polyester, applied in the field of production system of polyester masterbatch used to prepare polyester products, can solve the problems of greatly affecting the quality of polyester films, difficult production processes, films with poor gloss, etc., to achieve Excellent transparency, low cost, high light transmittance and one-way heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation of the polyester of the present application, taking PET as example, preferably produces bishydroxyethyl terephthalate through esterification or transesterification of terephthalic acid or dimethyl terephthalate and ethylene glycol, by It is industrially produced by a polycondensation method in which a catalyst is used for polycondensation under high temperature and vacuum. In a specific embodiment, terephthalic acid, ethylene glycol, cyclohexanedimethanol, catalyst and heat stabilizer can be used as raw materials for esterification; or terephthalic acid, ethylene glycol, isophthalic acid , catalyst and heat stabilizer as raw materials for esterification. In another specific embodiment, the catalyst is any compound of Ti / Si non-heavy metal catalyst and antimony trioxide, and the added amount thereof is 0.01-0.09% of the weight of the polyester. In another specific embodiment, the heat stabilizer is a phosphoric acid compound, and its addition amount is 0...

Embodiment 1

[0047] Add 5.0kg of terephthalic acid, 2.2kg of ethylene glycol, and 1.10g of germanium dioxide into a 20L general-purpose polymerization reactor, and carry out esterification reaction at 230-265°C and 0.2-0.3Mpa (gauge pressure). After reaching the theoretical value, the system pressure was released to normal pressure. To react under these conditions, add 1.025g of triethyl phosphate, stir at normal pressure for 10 minutes, raise the temperature and lower the pressure to 280°C and below 100Pa, carry out the reaction for 3 hours under these conditions, and finally extrude through polymerized melt, pelletize, After drying, PET polyester chips with an intrinsic viscosity of 0.75 dl / g were obtained.

[0048] Dry 60 parts by weight of airgel particles with a particle size of 0.5 μm at 120 ° C for 4 hours; dry 10 parts by weight of polylactic acid particles with a particle size of 0.5 mm or less at 110 ° C for 4 hours; Polystyrene particles below mm and 5 parts by weight of polyet...

Embodiment 2

[0052] Add 5.0kg of terephthalic acid, 2.2kg of ethylene glycol, and 1.10g of germanium dioxide into a 20L general-purpose polymerization reactor, and carry out esterification reaction at 230-265°C and 0.2-0.3Mpa (gauge pressure). After reaching the theoretical value, the system pressure was released to normal pressure. To react under these conditions, add 1.025g of triethyl phosphate, stir at normal pressure for 10 minutes, raise the temperature and lower the pressure to 280°C and below 100Pa, carry out the reaction for 3 hours under these conditions, and finally extrude through polymerized melt, pelletize, After drying, PET polyester chips with an intrinsic viscosity of 0.75 dl / g were obtained.

[0053] Dry 70 parts by weight of airgel particles with a particle diameter of 10 μm at 120 ° C for 4 hours; dry 15 parts by weight of polylactic acid particles with a particle size of 0.5 mm or less at 110 ° C for 4 hours; The following polystyrene pellets were dried at 110°C for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com