Thulium-erbium-dysprosium triple-doped lead fluoride intermediate infrared laser crystal, preparation method and application

A technology of heterogeneous lead fluoride and infrared laser, applied in chemical instruments and methods, lasers, crystal growth, etc., to improve pump absorption efficiency, suppress self-termination bottleneck effect, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Tm 0.01 Er 0.01 Dy 0.01 Pb 0.97 f 2 Crystal Growth Preparation

[0023] PbF 2 (99.999%), TmF 3 (99.999%), ErF 3 (99.999%) and DyF 3 (99.999%) are fully mixed according to the molar ratio of the proportioning equation, put into a self-made graphite crucible and sealed after fluorination treatment. Place the crucible in the high-temperature zone of the downhill furnace at a temperature of 980°C for 6 hours, and keep it warm for 4 hours to fully melt it. The growth atmosphere is N 2 gas, the crucible grows at a rate of 1.2-1.8mm / h, and the temperature gradient in the growth area is kept at 20-80°C / cm; h rate to cool slowly to room temperature.

Embodiment 2

[0024] Example 2: Tm 0.02 Er 0.01 Dy 0.005 Pb 0.965 f 2 Crystal Growth Preparation

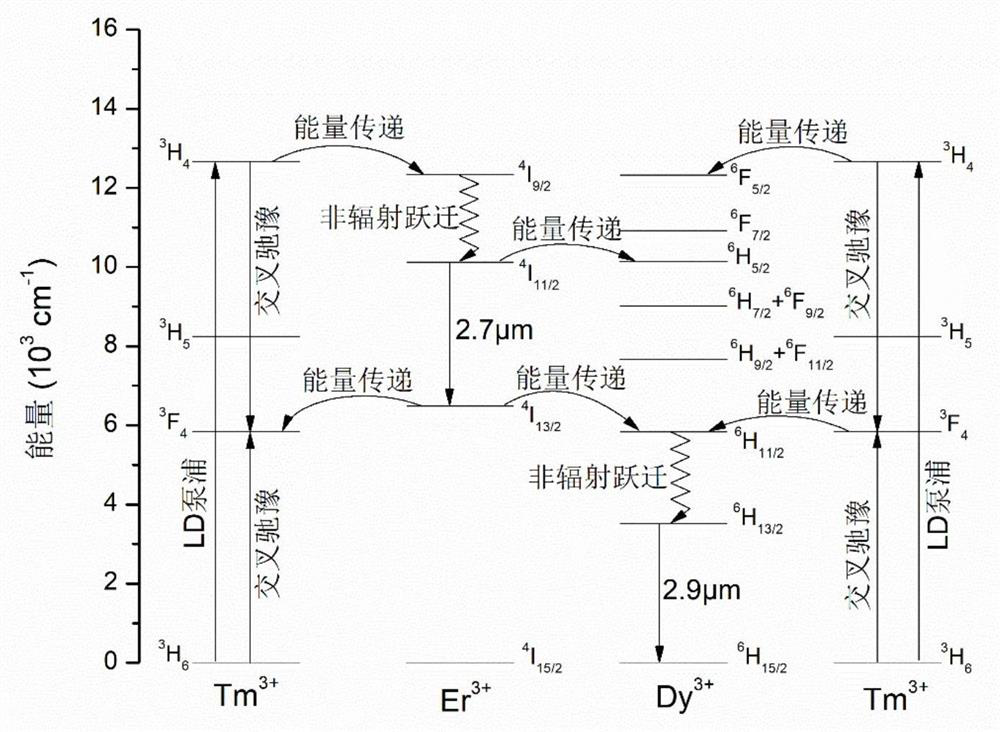

[0025] PbF 2 (99.999%), TmF 3 (99.999%), ErF 3 (99.999%) and DyF 3 (99.999%) are fully mixed according to the molar ratio of the proportioning equation, put into a self-made graphite crucible and sealed after fluorination treatment. Place the crucible in the high-temperature zone of the downhill furnace at 1060°C for 8 hours, and keep it warm for 4 hours to fully melt it. The growth atmosphere is N 2 gas, the crucible grows at a rate of 1.4-1.6mm / h, and the temperature gradient in the growth area is kept at 20-60°C / cm; Slowly cooled to room temperature at rate h, the PbF obtained after the end of the growth 2 The laser crystal has good optical quality. Schematic diagram of the sensitization and deactivation mechanism of thulium, erbium and dysprosium tri-doped lead fluoride laser crystals. figure 1 shown.

Embodiment 3

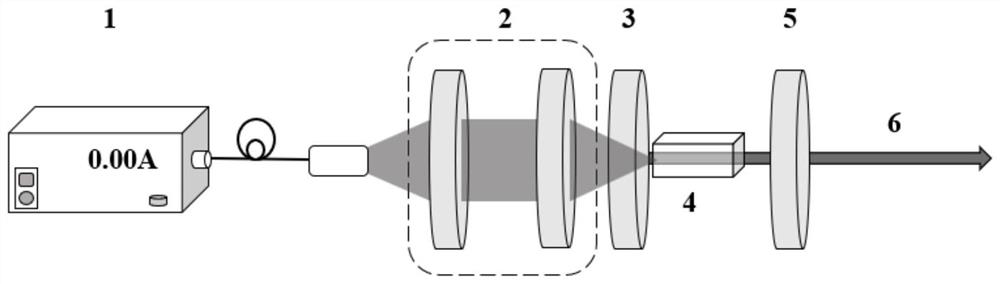

[0026] Example 3: Tm 0.02 Er 0.02 Dy 0.01 Pb 0.95 f 2 The application of crystals in mid-infrared continuous laser devices will PbF 2 (99.999%), TmF 3 (99.999%), ErF 3 (99.999%) and DyF 3 (99.999%) are fully mixed according to the molar ratio of the proportioning equation, put into a self-made graphite crucible and sealed after fluorination treatment. Place the crucible in the high-temperature zone of the downhill furnace at a temperature of 1080°C for 8 hours, and keep it warm for 6 hours to fully melt it. The growth atmosphere is N 2 gas, the crucible grows at a rate of 1.5-1.8mm / h, and the temperature gradient in the growth area is kept at 20-50°C / cm; h rate to cool slowly to room temperature. After the growth, the crystals were taken out and directional cut, processed and polished, and spectroscopic analysis was performed to characterize their optical properties. Crystal samples are used in mid-infrared continuous laser devices such as figure 2 As shown, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com