Manganese-based flux-cored brazing filler metal as well as preparation method and application thereof

A manganese-based and brazing filler metal technology is applied in the field of manganese-based flux cored filler metals and their preparation, which can solve the problem that the technological performance of manganese-based filler metals, the performance of brazing joints, and the work quality and efficiency cannot be fully improved, and the manganese-based filler metals cannot be effectively expanded. Issues such as the promotion and application of the range of brazing filler metals, limiting the popularization and application of manganese-based brazing filler metals and manganese-based flux-cored brazing filler metals, to achieve the effect of improving process formability, improving forming processability, and promoting efficient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

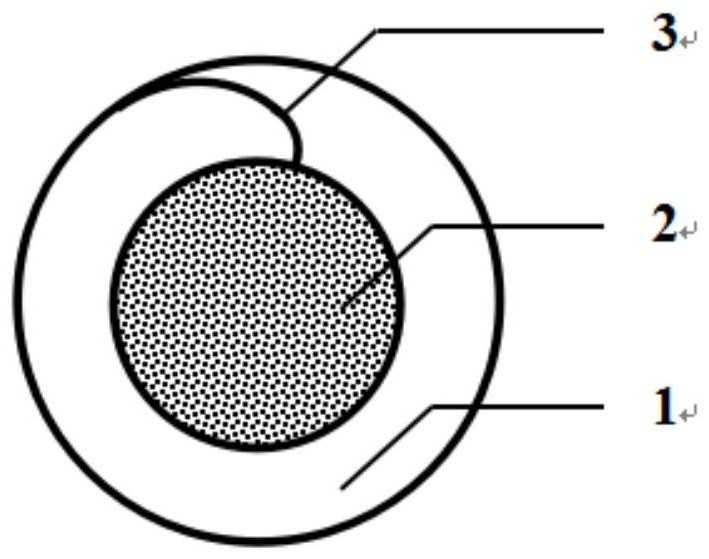

Image

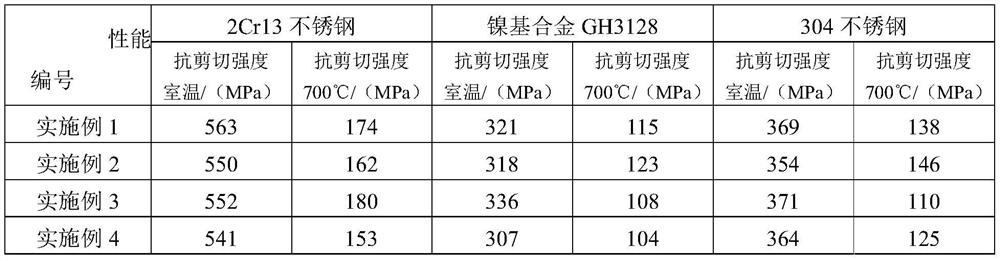

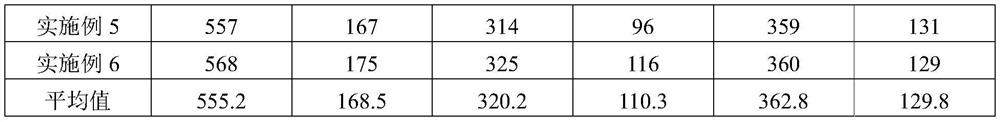

Examples

Embodiment 1

[0052] A manganese-based flux-cored solder, comprising 15% by mass of the inner core flux powder and 85% by mass of the manganese-based solder sheath covering the inner core flux powder, the manganese-based solder sheath is MnNiCuZnCrCoSn manganese Base alloy solder sheath, the mass percentages of the components in it are: Ni 30.0%, Cu 20.0%, Zn 12.5%, Cr 2.0%, Co5.0%, Sn 1.0%, Fe 0.3%, and the balance is Mn . The mass percent of each component of the flux powder is: 15.0% of borax, 56.5% of boric acid, 2.0% of calcium fluoride, 1.5% of potassium fluoride, 15.0% of potassium hydrogen fluoride and 10% of potassium fluoroborate.

[0053] The preparation process of the above-mentioned manganese-based flux core solder is:

[0054] Step 1. Carry out gas slag combined protection smelting for the solder alloy raw material: according to the mass percentage of the above solder alloy composition, put the prepared solder alloy raw material into the gas slag combined protection smelting ...

Embodiment 2

[0064] A manganese-based flux-cored solder, comprising 14% by mass of the inner core flux powder and 86% by mass of the manganese-based solder sheath covering the inner core flux powder, the manganese-based solder sheath is MnNiCuZnCrCoSn manganese Base alloy solder sheath, the mass percentages of the components in it are: Ni 28.5%, Cu 23.0%, Zn 13.5%, Cr 3.0%, Co4.4%, Sn 0.9%, Fe 0.24%, and the balance is Mn . The mass percent of each component of the flux powder is: 16.0% of borax, 51.5% of boric acid, 2.5% of calcium fluoride, 2.0% of potassium fluoride, 17.0% of potassium hydrogen fluoride and 11.0% of potassium fluoroborate.

[0065] The preparation process of the above-mentioned manganese-based flux core solder is:

[0066] Step 1. Carry out gas slag combined protection smelting for the solder alloy raw material: according to the mass percentage of the above solder alloy composition, put the prepared solder alloy raw material into the gas slag combined protection smelti...

Embodiment 3

[0076] A manganese-based flux-cored solder, comprising 13% by mass of the inner core flux powder and 87% by mass of the manganese-based solder sheath covering the inner core flux powder, the manganese-based solder sheath is MnNiCuZnCrCoSn manganese Base alloy solder sheath, the mass percentages of the components in it are: Ni 27.0%, Cu 26.0%, Zn 14.5%, Cr 4.0%, Co3.8%, Sn 0.8%, Fe 0.18%, and the balance is Mn . The mass percent of each component of the flux powder is: 17.0% of borax, 46.5% of boric acid, 3.0% of calcium fluoride, 2.5% of potassium fluoride, 19.0% of potassium hydrogen fluoride and 12.0% of potassium fluoroborate.

[0077] The preparation process of the above-mentioned manganese-based flux core solder is:

[0078] Step 1. Carry out gas slag combined protection smelting for the solder alloy raw material: according to the mass percentage of the above solder alloy composition, put the prepared solder alloy raw material into the gas slag combined protection smelti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com