Preparation method of porous modified activated carbon-aluminum oxide composite desulfurization adsorbent

A composite adsorption and alumina technology is applied in the preparation of porous modified activated carbon-alumina composite desulfurization adsorbents, and the preparation of porous modified activated carbon-alumina-based desulfurization adsorbents, which can solve the problem of single sulfide selectivity and temporary No problems such as adsorption of sulfide were found, and the effect of improving adsorption and removal capacity, changing easy pulverization, and improving desulfurization efficiency was achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Deep adsorption desulfurization of sulfur-containing fuel oil in a refinery in Fushun City, Liaoning Province

[0038] Treatment object: Sulfur-containing fuel oil from a refinery in Fushun City, Liaoning Province, with a sulfur content of 15ppm, of which thiophene sulfides account for about 70% of the sulfur content, and mercaptans and mercaptans account for about 30% of the sulfur content.

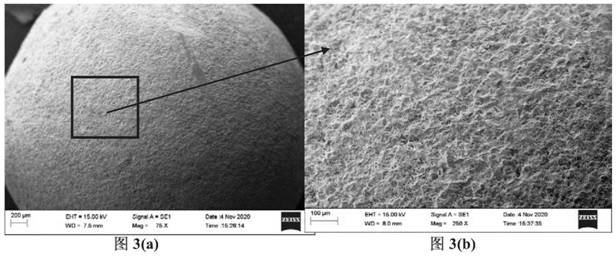

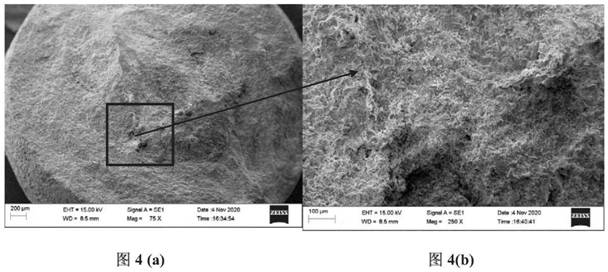

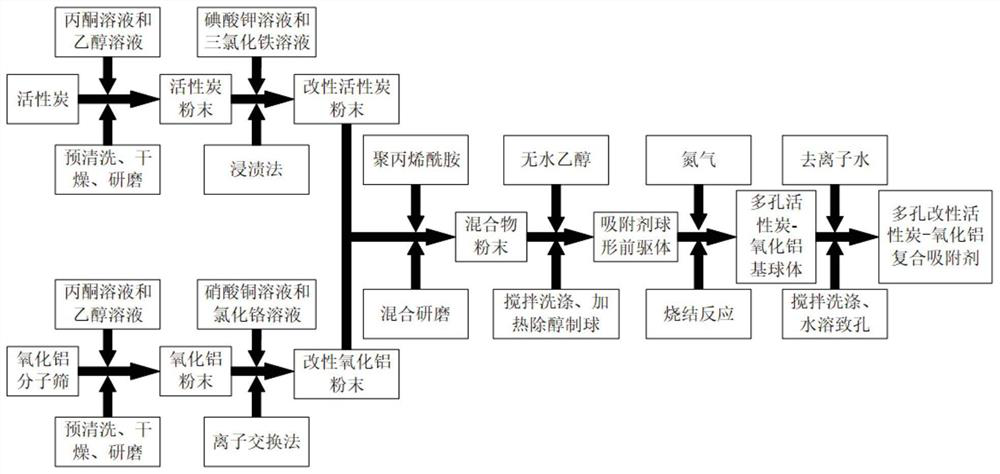

[0039] Preparation of porous modified activated carbon-alumina composite adsorbent: using the method described in the present invention, weigh 500 g of alumina molecular sieve and 100 g of activated carbon, and soak the raw material alumina molecular sieve and activated carbon in ethanol solution and acetone solution for 3 hours, Then transfer it to an ultrasonic cleaner for ultrasonic cleaning for 30 minutes, dry it in an incubator at 60°C for 10 hours, take it out for use; add 500 mL of 1mol / L copper nitrate to the pre-cleaned alumina molecular sieve , 500mL mol / L cad...

Embodiment 2

[0041] Example 2: Deep removal of hydrogen sulfide in a natural gas product produced by a natural gas company in Shanghai

[0042] Target of treatment: A natural gas product produced by a natural gas company in Shanghai, containing hydrogen sulfide content of 8000ppm-12000ppm.

[0043] Preparation of porous modified activated carbon-alumina composite adsorbent: using the method described in the present invention, weigh 200 g of alumina molecular sieve and 100 g of activated carbon, and soak the raw materials of alumina molecular sieve and activated carbon in ethanol solution and acetone solution for 3 hours, Then transfer it to an ultrasonic cleaner for ultrasonic cleaning for 30 minutes, dry it in an incubator at 60°C for 8 hours, take it out for use; add 200 mL of 1 mol / L copper nitrate to the pre-cleaned alumina molecular sieve , 200mL of 1mol / L cadmium chloride solution, heated and refluxed for 3 hours, washed and filtered with distilled water for 3 times, dried in a const...

Embodiment 3

[0045] Example 3: Adsorption and Removal of Blast Furnace Gas Sulfides of a Steel Co., Ltd. in Hebei Province

[0046] Object of treatment: The blast furnace gas of a steel company in Hebei Province contains sulfides, which are mainly divided into organic sulfur and inorganic sulfur. Organic sulfur (COS, C 2 S) content is about 80-140mg / Nm 3 , inorganic sulfur (H 2 S) content is about 25-45mg / Nm 3 .

[0047] Preparation of porous modified activated carbon-alumina composite adsorbent: using the method described in the present invention, weigh 500g of alumina molecular sieve and 200g of activated carbon, and soak the raw materials of alumina molecular sieve and activated carbon in ethanol solution and ketone solution for 4 hours , and then transferred to an ultrasonic cleaner for ultrasonic cleaning for 30 minutes, dried in a thermostat at 60°C for 10 hours, and taken out for use; add 500 mL of 1mol / L nitric acid to the pre-cleaned alumina molecular sieves Copper, 500mL of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com