Carbon nanomaterial prepared from waste tires as well as synthesis method and application of carbon nanomaterial

A nano-carbon material and synthesis method technology, applied in the field of desulfurization, can solve problems affecting the recycling of adsorbents, equipment corrosion, etc., and achieve the effect of improving adsorption and removal capacity, small particle size, and high adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of the carbon nano material that is made by waste tire, comprises the following steps:

[0027] 1) Weigh 6g of waste tires and 10.2g of KOH into a beaker, add 50mL of distilled water, and stir at 60°C for 12h.

[0028] 2) Washing, vacuum filtration to obtain a black solid, drying at 80°C for 12 hours, after drying, take 1 g of the black solid and 1 g of NaHCO 3 Grind and mix, put the mixture into a heating tube furnace and raise the temperature to 800°C at a rate of 5°C / min, keep it for 1h, and then cool down naturally.

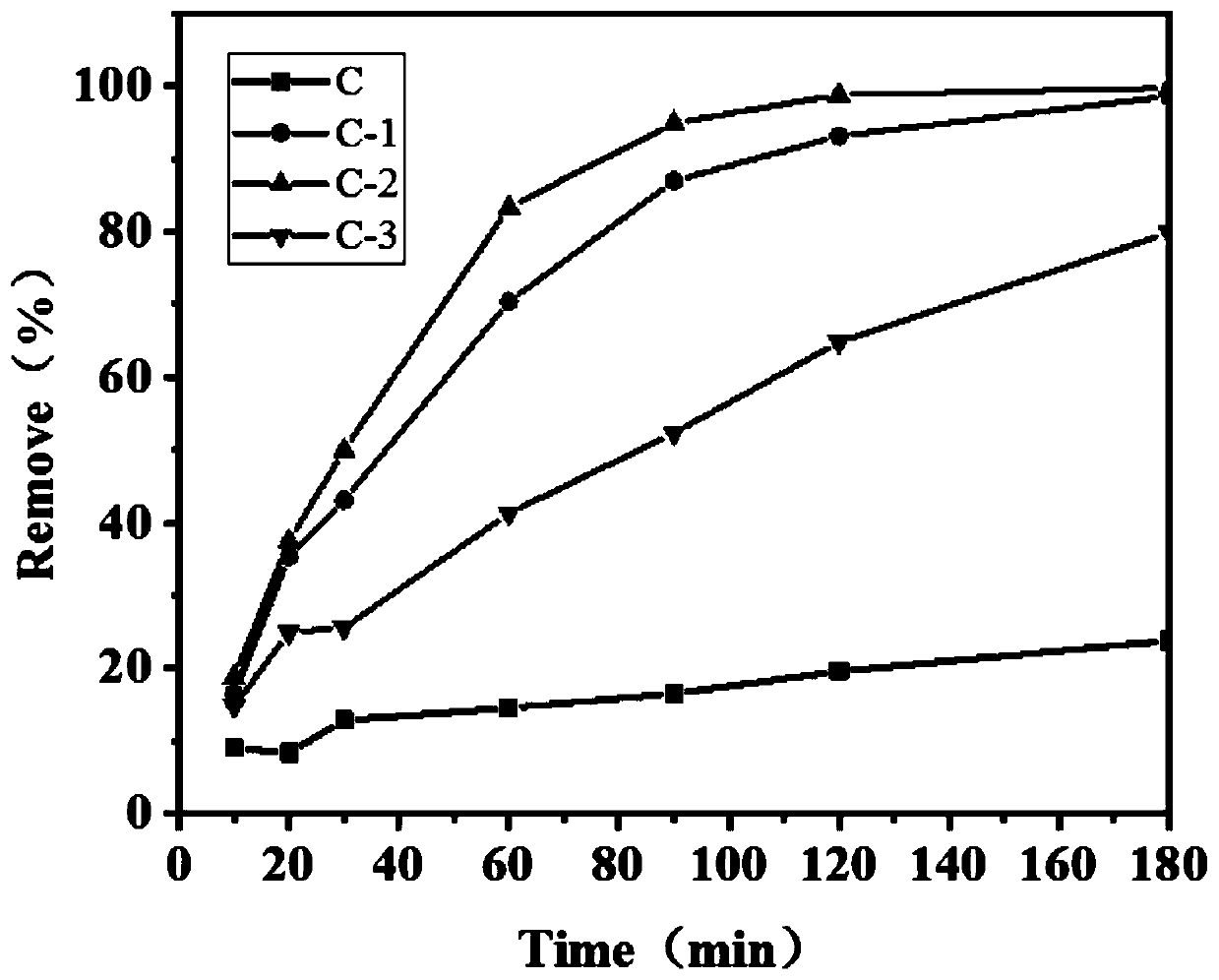

[0029] 3) Take out the black product in the tube furnace, wash it until neutral, and then place it in an oven at 80°C for 12 hours to obtain ultrafine particles of carbon nanomaterials made from waste tires, which are designated as C-1.

[0030] The synthesized nano-carbon material has a specific surface area of 78m 2 / g, the average particle diameter is 76.9nm.

Embodiment 2

[0032] A kind of preparation method of the carbon nano material that is made by waste tire, comprises the following steps:

[0033] 1) Weigh 6g of waste tires and 10.2g of KOH into a beaker, add 50ml of distilled water, and stir at 60°C for 12h.

[0034] 2) Wash and vacuum filter to obtain a black solid, dry at 80°C for 12 hours, take 1 g of the black solid and 1.5 g of NaHCO after drying 3 Grind and mix, put the mixture into a heating tube furnace and raise the temperature to 800°C at a rate of 5°C / min, keep it for 1h, and then cool down naturally.

[0035] 3) Take out the black product in the tube furnace, wash it until neutral, and then place it in an oven at 80°C for 12 hours to obtain ultrafine particles of carbon nanomaterials made from waste tires, which are designated as C-2.

[0036] The synthesized nano-carbon material has a specific surface area of 99m 2 / g, the average particle diameter is 60.4nm.

Embodiment 3

[0038] A kind of preparation method of the carbon nano material that is made by waste tire, comprises the following steps:

[0039] 1) Weigh 6g of waste tires and 10.2g of KOH into a beaker, add 50mL of distilled water, and stir at 60°C for 13h.

[0040] 2) Washing, vacuum filtration to obtain a black solid, drying at 85°C for 12 hours, after drying, take 1 g of the black solid and 2 g of NaHCO 3 Grind and mix, put the mixture into a heating tube furnace and raise the temperature to 800°C at a rate of 5°C / min, keep it for 1h, and then cool down naturally.

[0041] 3) Take out the black product in the tube furnace, wash it until neutral, and then place it in an oven at 80°C for 12 hours to obtain ultrafine particles of carbon nanomaterials made from waste tires, which are denoted as C-3.

[0042] The synthesized nano-carbon material has a specific surface area of 83m 2 / g, the average particle size is 72.6nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com