A preparation method of halloysite/carbon composite adsorbent for removing NO

A carbon composite, adsorbent technology, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., to achieve the effects of improved adsorption and removal capacity, large energy consumption, and reduced specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

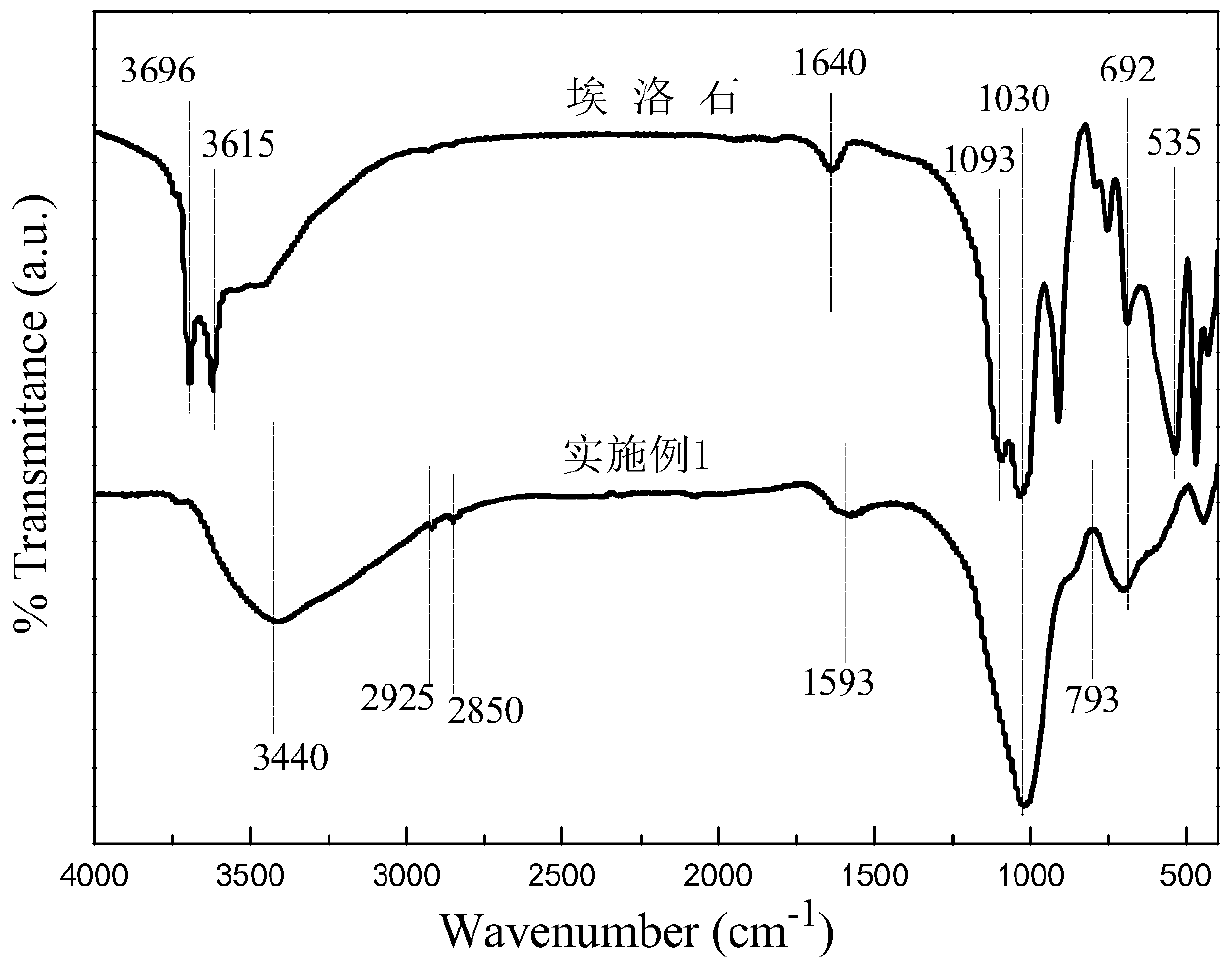

[0022] This embodiment prepares halloysite / carbon composite adsorbent according to the following steps:

[0023] (1) Pulverizing halloysite raw ore and passing through a 300-mesh sieve to obtain halloysite powder;

[0024] (2) Weigh 8g of potassium carbonate powder and dissolve it in 60mL of deionized water to obtain a potassium carbonate solution; weigh 2g of halloysite powder and 4g of chitosan respectively, add them to the potassium carbonate solution, immerse and stir for 4h, and dry at 105°C A mixed material is obtained.

[0025] (3) Put the mixed material in the horizontal tube sintering furnace, N 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and the activation was maintained for 90 minutes. After cooling to room temperature, a black product was obtained;

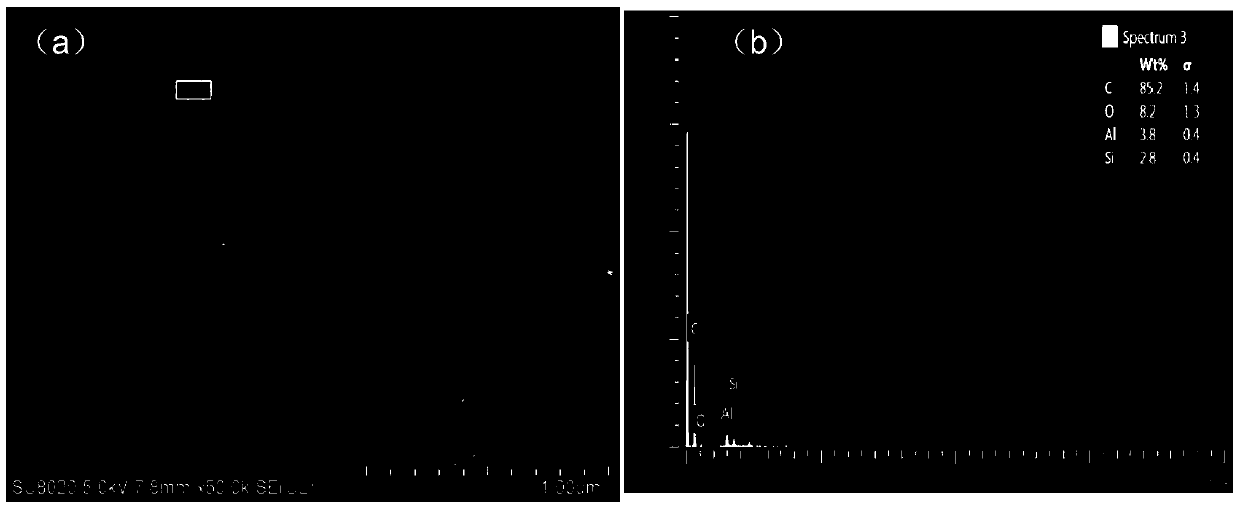

[0026](4) Wash the black product with 0.1 mol / L hydrochloric acid solution to remove residual activator, and then wash the sample with 60°C deionized water until neutral. The w...

Embodiment 2

[0037] This embodiment prepares halloysite / carbon composite adsorbent according to the following steps:

[0038] (1) Pulverizing halloysite raw ore and passing through a 300-mesh sieve to obtain halloysite powder;

[0039] (2) Weigh 8g of potassium carbonate powder and dissolve it in 60mL of deionized water to obtain a potassium carbonate solution; weigh 2g of halloysite powder and 4g of chitosan respectively, add them to the potassium carbonate solution, immerse and stir for 4h, and dry at 105°C A mixed material is obtained.

[0040] (3) Put the mixed material in the horizontal tube sintering furnace, N 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and the activation was maintained for 120 minutes. After cooling to room temperature, a black product was obtained;

[0041] (4) Wash the black product with 0.1 mol / L hydrochloric acid solution to remove residual activator, and then wash the sample with 60°C deionized water until neutral. The...

Embodiment 3

[0045] This embodiment prepares halloysite / carbon composite adsorbent according to the following steps:

[0046] (1) Pulverizing halloysite raw ore and passing through a 300-mesh sieve to obtain halloysite powder;

[0047] (2) Weigh 8g of potassium carbonate powder and dissolve it in 60mL of deionized water to obtain a potassium carbonate solution; weigh 2g of halloysite powder and 4g of chitosan respectively, add them to the potassium carbonate solution, immerse and stir for 4h, and dry at 105°C A mixed material is obtained.

[0048] (3) Put the mixed material in the horizontal tube sintering furnace, N 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and the activation was maintained for 150 minutes. After cooling to room temperature, a black product was obtained;

[0049] (4) Wash the black product with 0.1 mol / L hydrochloric acid solution to remove residual activator, and then wash the sample with 60°C deionized water until neutral. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com