Preparation method of nitrogen-doped graphene quantum dot hybrid membrane for selective adsorption of copper ions from mixed metal solutions

A technology of mixing metal and copper ions, applied in graphene, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of difficult separation and classification of heavy metal ions, few cycles of use, limited application value, etc., to eliminate metal ions. The effect of ion pollution, simple operation, easy recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of nitrogen-doped graphene quantum dots (N-GQDs) precursors:

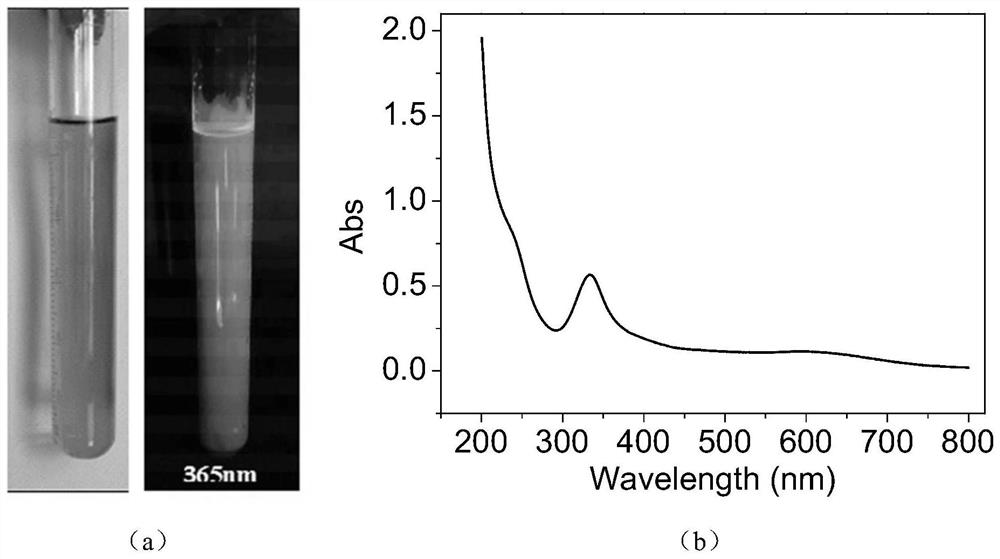

[0037] With the molar ratio of citric acid (carbon source) and urea (nitrogen source) as 1:3, 0.21 g (1 mmol) of citric acid and 0.18 g (3 mmol) of urea were dissolved in 5 mL of water, and stirred to obtain a clear solution. It was placed in a polytetrafluoroethylene-lined reaction kettle, heated to 160° C., and kept for 4 h. The reaction solution was cooled to room temperature in the reactor, opened the solution in the reactor, and the solution was a clear yellow solution (such as figure 1 (a) shown on the left). As a zero-dimensional material, graphene quantum dots, in addition to having abundant edge effects, exhibit bright blue fluorescence under UV light at 365 nm.

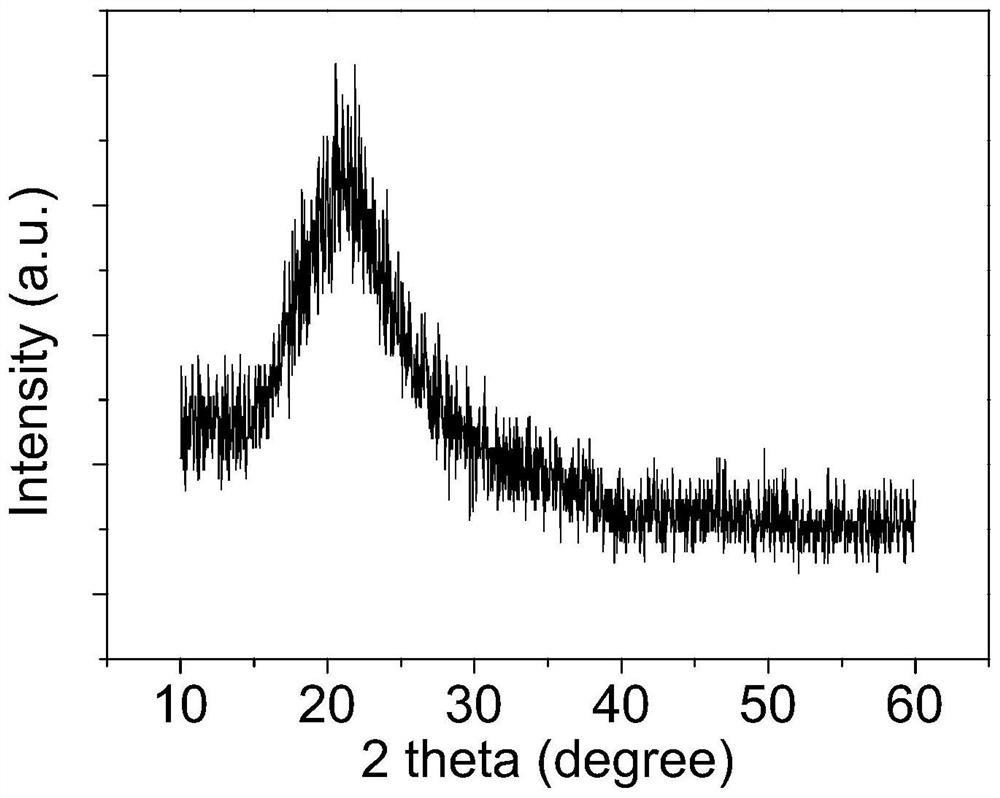

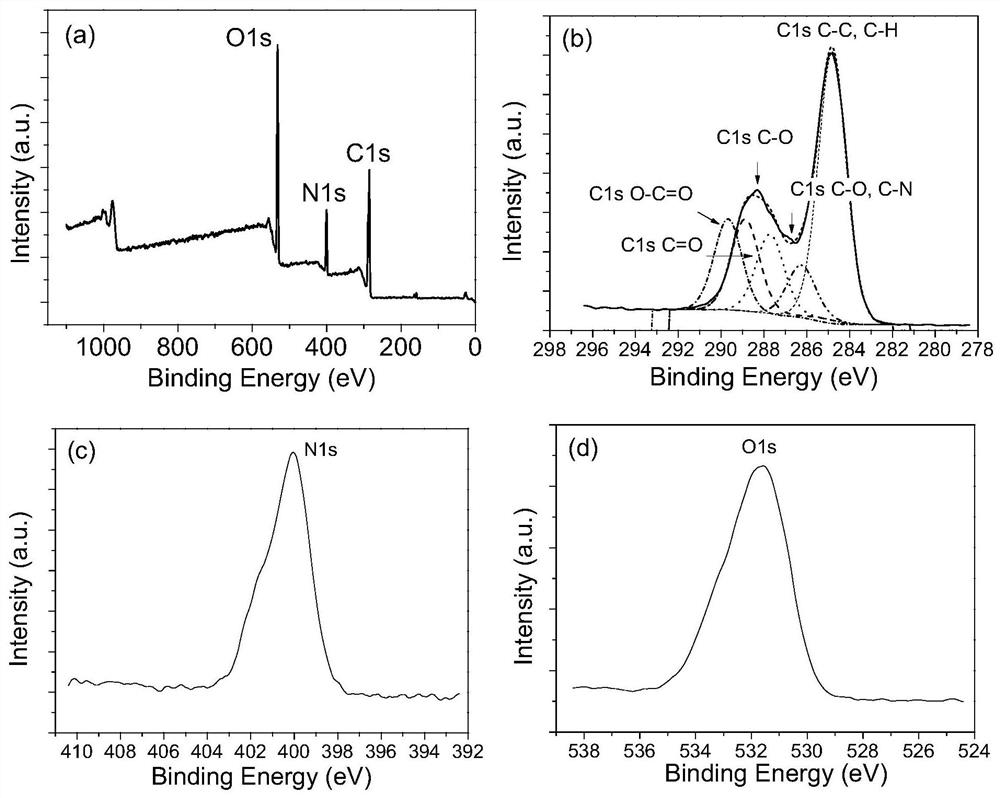

[0038] In order to further confirm that the clear yellow solution taken out from the reaction kettle is the N-GQDs precursor, the clear yellow solution is detected by ultraviolet absorption spectrum, and the maximum ultraviol...

Embodiment 2

[0043] At room temperature, take a certain amount of N-GQDs precursor powder prepared in Example 1, add 10 mL of water, stir for 10 min, until the N-GQDs precursor powder is completely dissolved, then add PVA (5wt%) solution, and stir at room temperature for 1 h , and then add glutaraldehyde, ethyl orthosilicate and silane coupling agent WD-51 with a concentration of 25% by mass respectively under stirring conditions, and continue stirring for 4 hours to obtain a solution. The solution was placed in an ultrasonic cleaner, sonicated at 100KHz for 20 min to remove air bubbles in the solution, and allowed to stand for 12 h to obtain a film-forming liquid. The support PTFE sheet was separated, and then the membrane was dried at 40 °C for 12 h, and the N-GQDs hybrid membrane without support was obtained after cooling.

[0044] The content of N-GQDs precursor, glutaraldehyde, WD-51, TEOS and other raw materials in the hybrid membrane was changed, and the effect of the composition of...

Embodiment 3

[0050] According to the experimental results of Example 2, it can be seen that the addition amount of the N-GQDs precursor powder and the addition amount of the silane coupling agent WD-51 have the greatest influence on the performance of the N-GQDs hybrid film. Among them, it is suitable that the amount of N-GQDs precursor powder added does not exceed 0.5 g, and the amount of silane coupling agent WD-51 added is suitable in the range of 0.2 to 0.5 mL. Accordingly, by optimizing the ratio of raw materials (see Table 2), a series of N-GQDs hybrid membranes for adsorption and separation of metal ions from mixed metal solutions were prepared, which were marked as hybrid membranes A to G, respectively. Among them, the addition amount of N-GQDs precursor powder in A-D hybrid films increases sequentially, and the addition amount of silane coupling agent WD-51 in E-G hybrid films increases sequentially.

[0051] Table 2. Raw material ratio table of N-GQDs hybrid membrane A~G

[0052...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com