Preparation of a hybrid membrane for the selective separation of copper from mixed metal solutions

A mixed metal, selective technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the difficulty of separating and grading mixed heavy metal ion solutions, and cannot selectively separate copper ions. Application Value is limited and other problems, to achieve the effect of increasing adsorption and removal capacity, less steps, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a hybrid membrane for selectively separating copper from a mixed metal solution, the preparation steps of which are as follows:

[0039] (1) The preparation of the PVA aqueous solution of 5% (mass ratio): in the 250mL container that agitator is housed, add 25g average degree of polymerization and be the polyvinyl alcohol (PVA) of 1750 ± 50, add appropriate amount of deionized water again, constantly Stir the mixture of PVA and water in the container until the PVA is completely dissolved, continue to stir for 2 hours to obtain a solution, then transfer the solution to a 500mL volumetric flask, add a certain amount of deionized water, shake evenly, and then add an appropriate amount of deionized water Until the solution reaches the full scale of the volumetric flask, shake it evenly to prepare 500mL of PVA aqueous solution with a concentration of 5% by mass.

[0040] (2) Preparation of the hybrid precursor: under the temperature condition of 20°C (u...

Embodiment 2

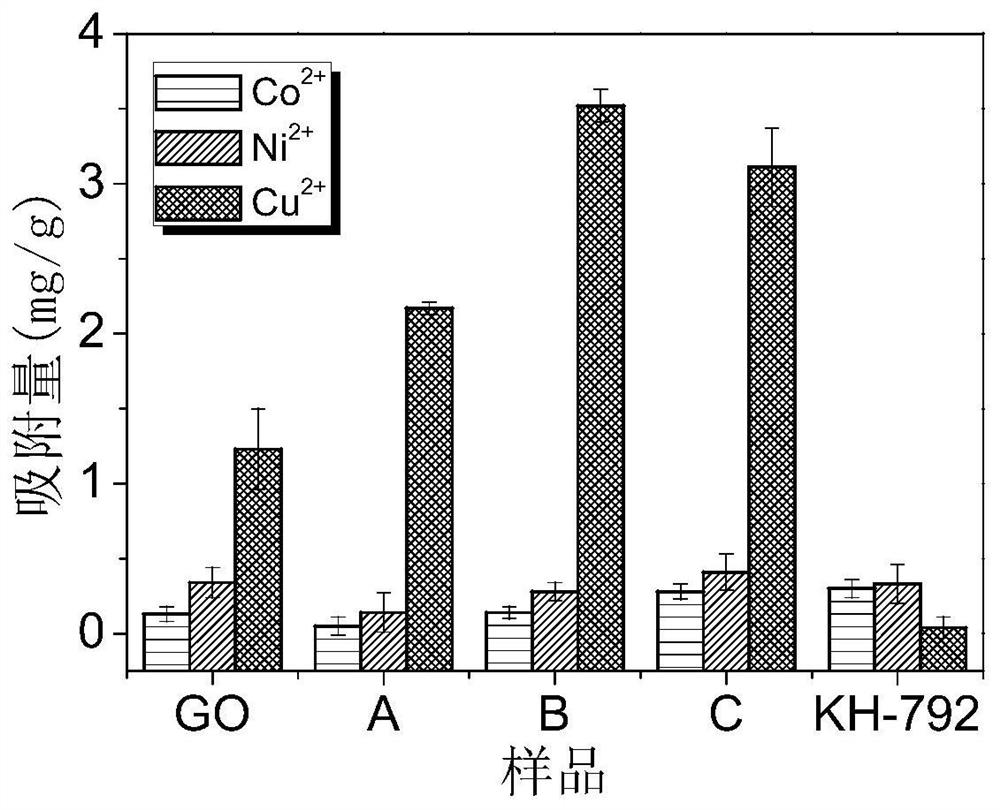

[0044] Using the same experimental device and operating steps as in Example 1, changing the material ratio, and adding different amounts of silane coupling agent KH-792 to the GO solution, a series of hybrids without supports with different silicon contents can be prepared. film. Among them, the mixture mass ratio (mg / mg) of graphene oxide and silane coupling agent KH-792 is GO:KH-792=150:50, which is marked as hybrid film sample A; graphene oxide and silane coupling agent KH- The mass ratio (mg / mg) of 792 is GO:KH-792=100:100, which is marked as hybrid film sample B; the mass ratio (mg / mg) of the mixture of graphene oxide and silane coupling agent KH-792 is GO: KH-792=50:150 is marked as hybrid membrane sample C.

[0045] The three kinds of hybrid film samples prepared above were mixed with pure GO-doped PVA film (that is, the film prepared by adding pure GO to 5% PVA solution), pure KH-792-doped PVA film (that is, pure KH-792 is added to the film prepared in 5% PVA solutio...

Embodiment 3

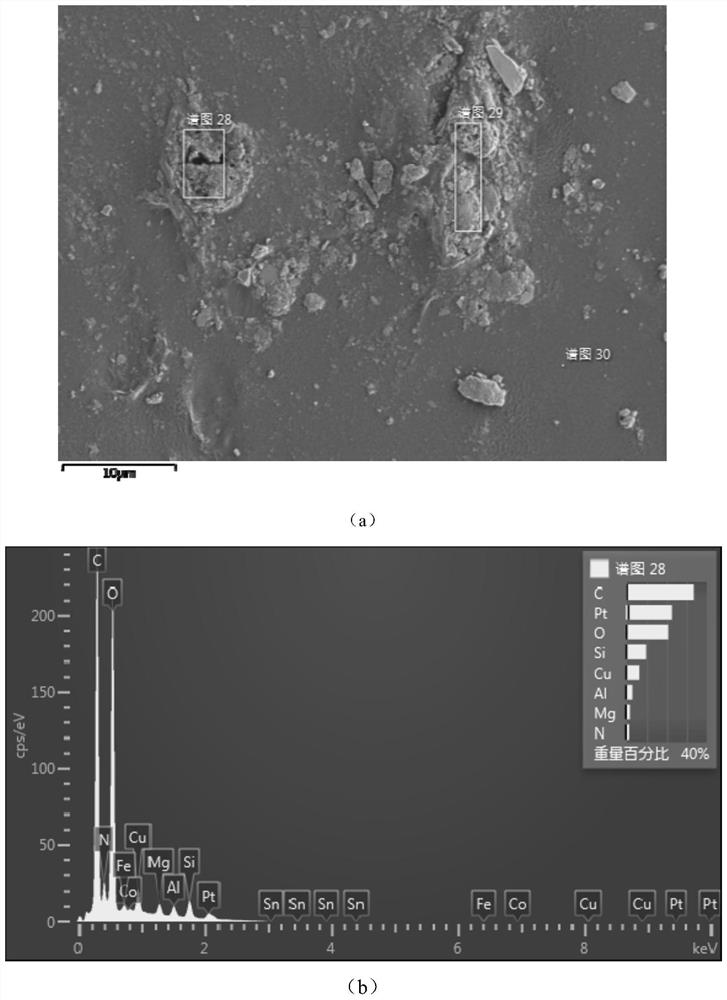

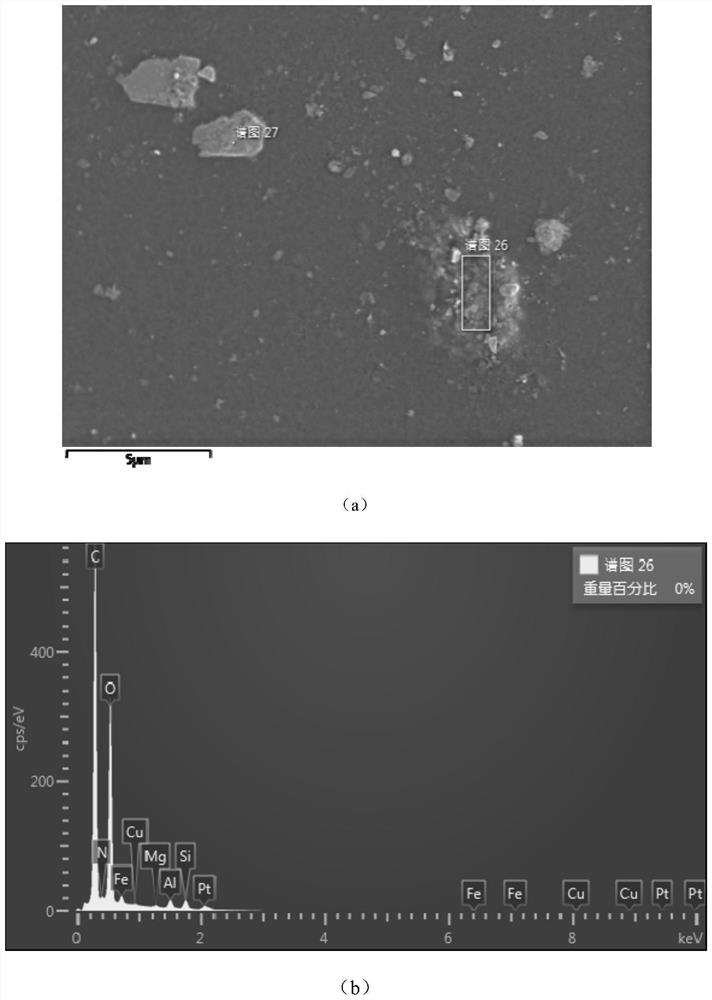

[0050] Select the pure GO-doped PVA film prepared in Example 2 and the hybrid film sample B with the best adsorption effect on copper ions, and observe their effect on Cu in the mixed aqueous solution of metal ions. 2+ 、Co 2+ and Ni 2+ SEM morphology of the surface after adsorption, and use energy spectrum to verify; see if heavy metal ions are adsorbed on the surface of the hybrid membrane.

[0051] figure 2 Adsorption of Cu for the hybrid film sample B in Example 2 2+ 、Co 2+ and Ni 2+ SEM image (a) and EDS energy spectrum (b) of the surface after mixing metal ions. image 3 For pure GO doped PVA film adsorption Cu in embodiment 2 2+ 、Co 2+ and Ni 2+ SEM image (a) and EDS energy spectrum (b) of the surface after mixing metal ions. Compare figure 2 and image 3 As can be seen: figure 2 On the EDS energy spectrum of EDS, there is a relatively obvious Cu element peak with the strongest intensity, and the Co element peak is weaker, indicating that the copper conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com