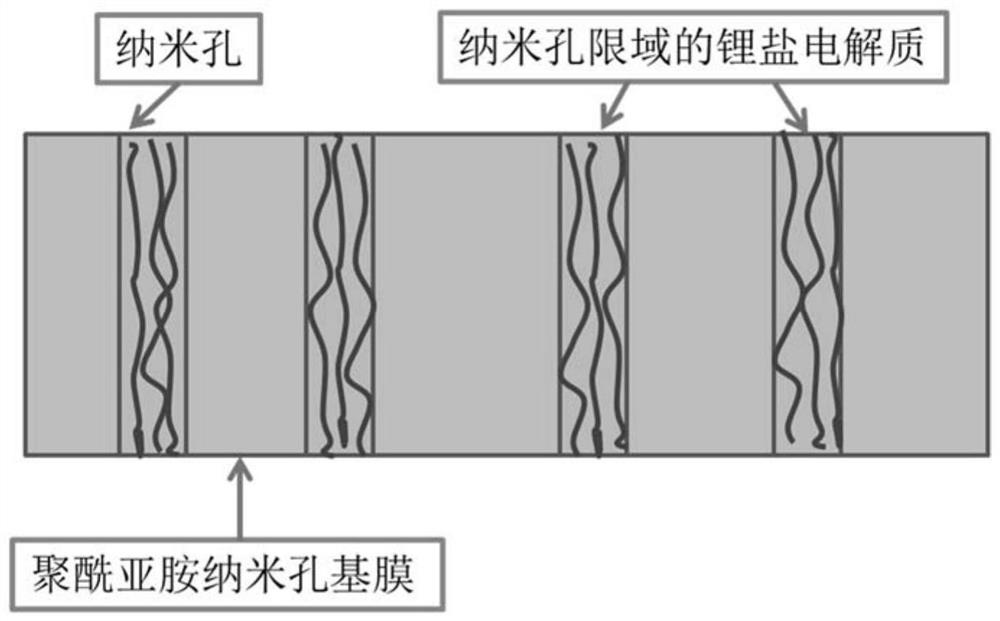

Nuclear pore film-based solid electrolyte film and preparation method thereof

A solid electrolyte and electrolyte technology, applied in non-aqueous electrolyte batteries, circuits, lithium batteries, etc., to achieve the effects of uniform pore size, controllable size, excellent mechanical properties and insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) The high-energy heavy ion beam provided by the heavy ion accelerator is heavy ion bismuth (the LET value (linear energy transfer) of the heavy ion in polyimide material is greater than 4.5eV / nm), and the ion energy is 9.8MeV / nm u, 6 micron polyimide (PI) film is irradiated vertically, and the irradiation density is 2*10 8 ions per square centimeter, the PI film after irradiation such as figure 2 shown.

[0048] 2) the PI membrane irradiated by heavy ions is etched in 12% sodium hypochlorite solution for 30 minutes at 60 degrees centigrade to obtain a PI nuclear pore membrane with a vertical nanopore of 3 hundred nanometers in diameter, such as image 3 shown.

[0049] 3) Coat the prepared PI nuclear pore membrane with a lithium salt-containing PEO electrolyte solution, evaporate the solvent at 60 degrees Celsius for 12 hours, and then heat it to 220 degrees Celsius for 16 hours in an inert atmosphere to melt the polymer electrolyte into the polymer electrolyte. i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com