Novel MEMS high-Q-value non-solenoid integrated inductor and preparation method thereof

A technology integrating inductors and solenoids, applied in the field of microelectronics, can solve problems such as difficulty, high process cost, and subsequent packaging difficulties, and achieve the effects of suppressing substrate loss, reducing ohmic loss, and suppressing eddy current effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

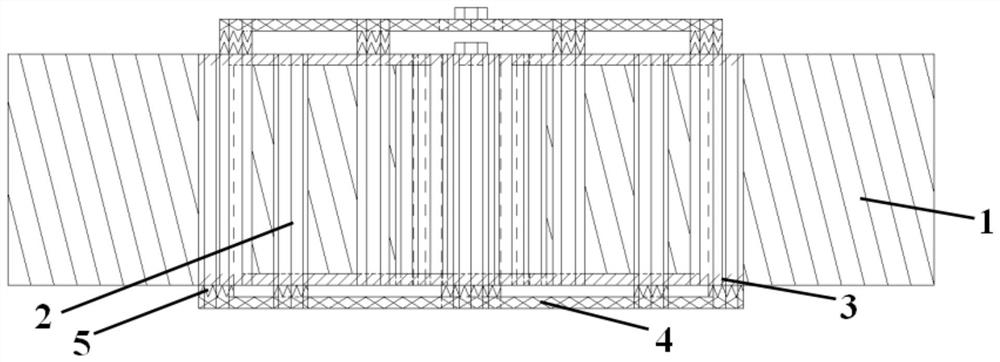

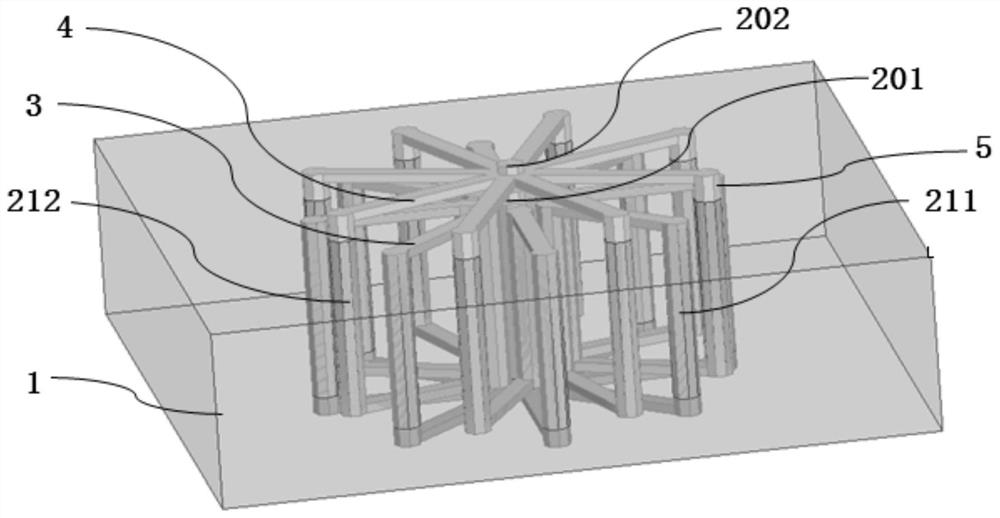

[0062] The specific preparation process of a new type of MEMS high-Q non-solenoid integrated inductor is as follows:

[0063] S1, such as Figure 3a As shown, a photoresist 6 is coated on a 4-inch silicon wafer (silicon substrate 1), prebaked, exposed, developed, and hardened. 2 The deep reactive ion etching (DRIE) process of the plasma low-temperature etching method of the reactive gas forms a TSV through hole with a smooth and steep side wall of 100 μm deep and a radius of 7.5 μm regular octagonal column on the silicon wafer. SiH based on sidewall 4 / O 2 The gas uses Low Pressure Chemical Vapor Deposition (LPCVD) to deposit a layer of 1 μm thick low-temperature oxide (LTO), which is used to isolate the inductor coil and the silicon base and reduce substrate loss. So far, a TSV via hole pattern with the number of inner TSV micro vias: the number of outer TSV micro vias=8:2*8 is formed. Among them, the inner TSV micro-vias correspond to the inner micro-copper column group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com