In-situ chemical oxidation remediation method for soil contaminated by benzene series

An in-situ chemical oxidation and polluted soil technology, which is applied in the field of in-situ chemical oxidation of soil, can solve the problems of high disposal cost, high disposal cost, soil loss of function, etc., to prolong effective reaction time, save restoration input cost, and high The effect of redox potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

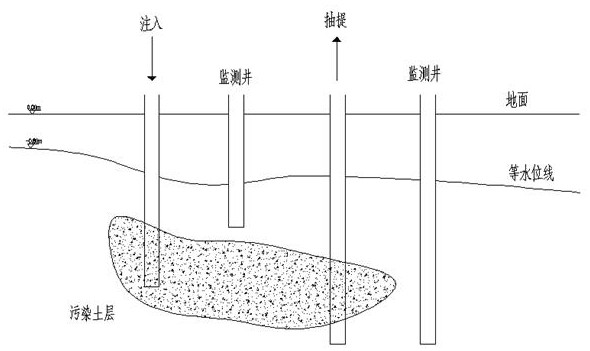

Method used

Image

Examples

Embodiment 1

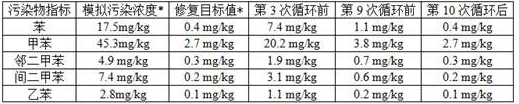

[0054] A chemical polluted site, the main pollutants are benzene (11.5mg / kg), toluene (30.5mg / kg), o-xylene (3.2mg / kg), m-xylene (4.7mg / kg), ethylbenzene (1.7mg / kg), pollution depth 8m, pollution area 40000m 2 , the site is open and flat, and the soil layer in the site is mainly silt and silt. By simulating the field conditions to carry out small tests, it is determined that the soil remediation agent combination is a mixed reagent of hydrogen peroxide and ferrous sulfate, and the injection method is tube well injection. The results of the small test show that after multiple cycles of chemical oxidation, the concentration of each pollutant is as follows: benzene (0.4mg / kg), toluene (2.7mg / kg), o-xylene (0.3mg / kg), m-xylene (0.2mg / kg), ethylbenzene (0.1mg / kg).

[0055] To simulate a small test, take 10g of contaminated soil samples in a conical flask, add 50mL of water, and add 30% H to the conical flask respectively. 2 o 2 , 30%H 2 o 2 +FeSO 4 、Na 2 S 2 o 8 For diff...

Embodiment 2

[0061] Material leakage in a chemical plant caused surrounding soil pollution. The main pollutants were benzene (7.3mg / kg), toluene (1.4mg / kg), and styrene (21.5mg / kg). The pollution depth was 6m and the pollution area was 15,000m 2 , the site is densely covered with structures, and the soil layer in the site is mainly silt and silty clay. By simulating field conditions to carry out small tests, it is determined that the soil remediation agent combination is a mixed reagent of hydrogen peroxide, ferrous sulfate, and sodium persulfate, and the injection method adopts a combination of well point injection and jet injection. The results of the small test show that after repeated cycles of chemical oxidation, the concentration of each pollutant is as follows: benzene (0.3mg / kg), toluene (0.4mg / kg), styrene (2.6mg / kg).

[0062] To simulate a small test, take 10g of contaminated soil samples in a conical flask, add 50mL of water, and add 30% H to the conical flask respectively. 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com