Post-treatment purification method of olopatadine hydrochloride

A technology of olopatadine hydrochloride and a purification method, which is applied in the field of drug purification, can solve problems such as affecting product yield, loss of target product, and difficulty in removing bromide ion impurities, so as to improve preparation yield and product purity, and reduce production cost , The effect of reducing the risk of bromide ion residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

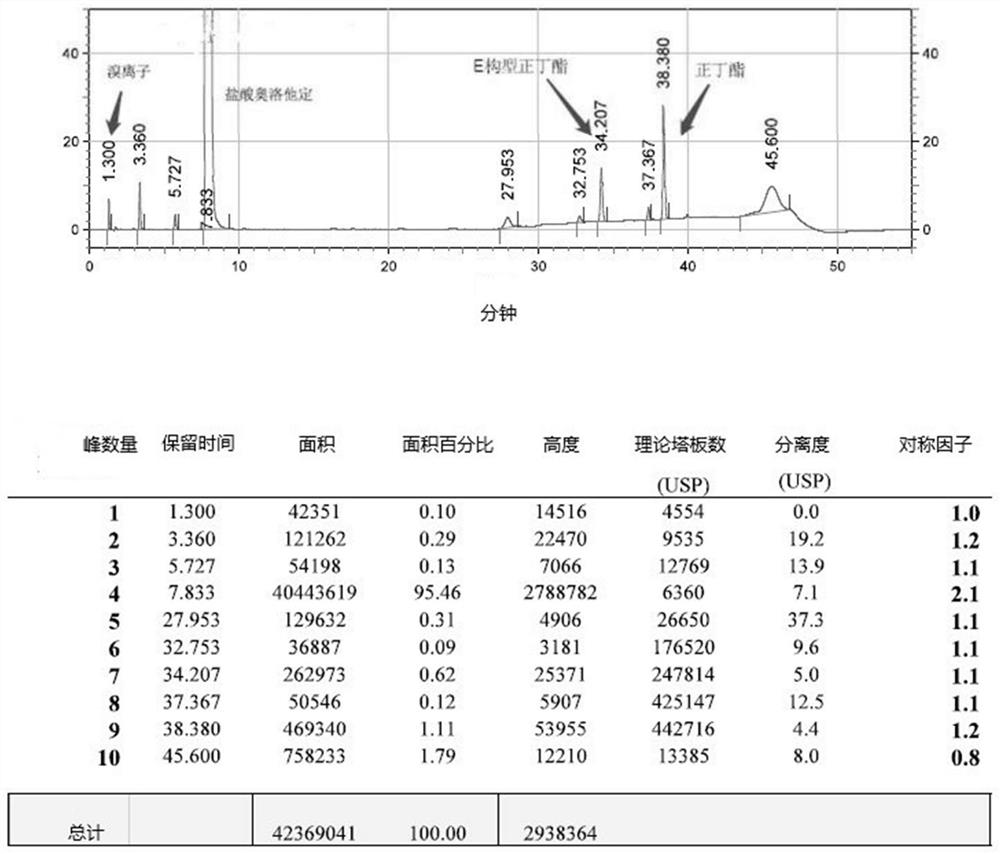

Embodiment 1

[0047] The preparation of embodiment 1 olopatadine hydrochloride crude product

[0048] Weigh [3-(dimethylamino)propyl]triphenylphosphine bromide hydrobromide (231.6g) and tetrahydrofuran (915ml) into a reaction flask, nitrogen protection, then stir in a cooling bath at -10°C ; Add BuLi (284.5g) dropwise to the system, keeping the temperature of the system at -10-10°C. After the drop is complete, stir for 2h; add dropwise a solution of isoket acid (61g) in tetrahydrofuran (305ml), and heat up to 55-60°C , Reaction 4h.

[0049] The reaction solution system was lowered to room temperature, and water (305ml) was added dropwise to quench the reaction; then NaCl (91.5g), NaOH (37g), and water (183ml) were added, and the temperature was raised to 55-60°C and stirred for 2h; the phases were separated, and the organic phase was reserved. Add 25% (w / w) sodium chloride solution (305ml) for washing, stir at 35-40°C for 30min, let stand to separate the phases, and keep the organic phas...

Embodiment 2

[0051] The preparation of embodiment 2 olopatadine hydrochloride crude product

[0052] Weigh [3-(dimethylamino)propyl]triphenylphosphine bromide hydrobromide (231.6g) and tetrahydrofuran (915ml) into a reaction flask, nitrogen protection, then stir in a cooling bath at -10°C ; Add BuLi (284.5g) dropwise to the system, keeping the temperature of the system at -10-10°C. After the drop is complete, stir for 2h; add dropwise a solution of isoket acid (61g) in tetrahydrofuran (305ml), and heat up to 55-60°C , Reaction 4h.

[0053] The reaction solution system was lowered to room temperature, and water (305ml) was added dropwise to quench the reaction; then NaCl (91.5g), NaOH (37g), and water (183ml) were added, and the temperature was raised to 55-60°C and stirred for 2h; the phases were separated, and the organic phase was reserved. Add 27% (w / w) sodium chloride solution (305ml) for washing, stir at 45-50°C for 30min, let stand to separate the phases, and keep the organic phas...

Embodiment 3

[0055] The preparation of embodiment 3 olopatadine hydrochloride crude product

[0056] Weigh [3-(dimethylamino)propyl]triphenylphosphine bromide hydrobromide (231.6g) and tetrahydrofuran (915ml) into a reaction flask, nitrogen protection, then stir in a cooling bath at -10°C ; Add BuLi (284.5g) dropwise to the system, keeping the temperature of the system at -10-10°C. After the drop is complete, stir for 2h; add dropwise a solution of isoket acid (61g) in tetrahydrofuran (305ml), and heat up to 55-60°C , Reaction 4h.

[0057] The reaction solution system was lowered to room temperature, and water (305ml) was added dropwise to quench the reaction; then NaCl (91.5g), NaOH (37g), and water (183ml) were added, and the temperature was raised to 55-60°C and stirred for 2h; the phases were separated, and the organic phase was reserved. Add 20% (w / w) sodium chloride solution (305ml) for washing, stir at 35-40°C for 30min, let stand to separate the phases, and keep the organic phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com