Copper smelting hazardous waste co-processing and valuable metal comprehensive recovery method

A technology for co-processing and hazardous waste, applied in the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high cost of solution purification, large amount of waste acid treatment, low concentration of dilute sulfuric acid, etc., and achieve comprehensive recovery of valuable metals. Good effect, large amount of wastewater treatment, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

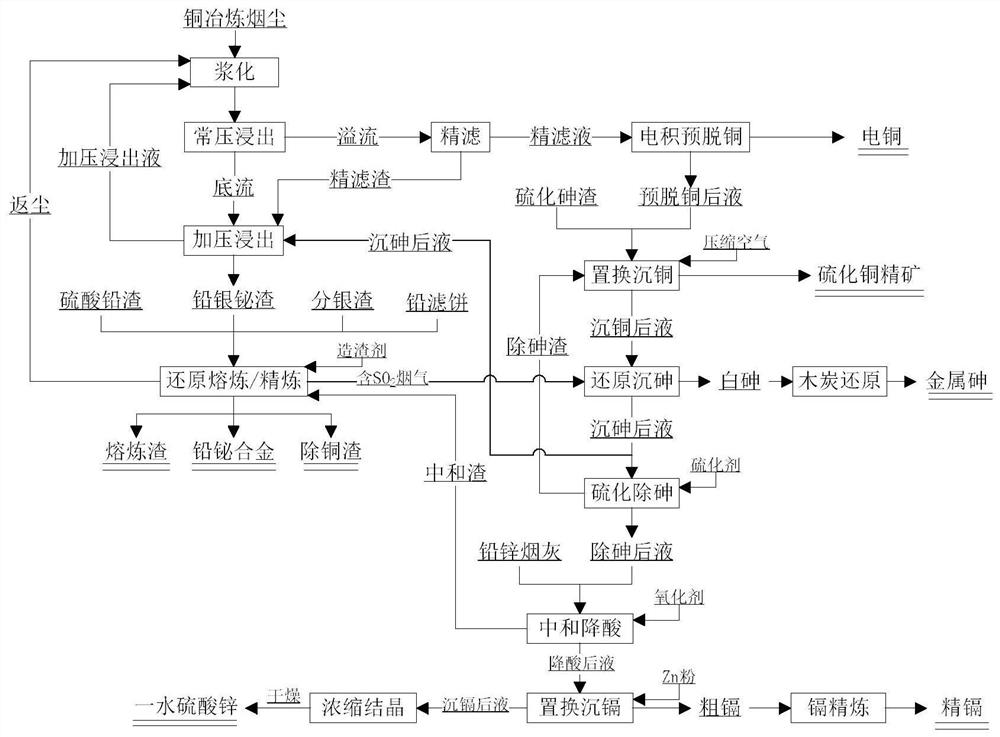

[0053] This embodiment provides a method for the co-processing of copper smelting hazardous waste and the comprehensive recovery of valuable metals. The main components of the copper smelting hazardous waste involved are shown in Table 1. The specific process is as follows figure 1 As shown, the steps are as follows:

[0054] Table 1 The main components of several copper smelting hazardous wastes (wt%, Au, Ag are g / t)

[0055] element Cu Pb Bi As Zn Au Ag Cd S Sb copper smelting dust 15.75 17.86 2.46 6.44 5.84 4.38 0.04 0.91 7.46 0.45 Arsenic sulfide slag 10.82 3.45 2.36 29.96 4.045 0.16 16.45 0.395 30.8 0.097 Silver slag 0.08 21.63 14.46 0.62 0.022 5.79 1003 / 7.01 9.39 Lead filter cake 3.36 47.59 2.65 0.47 1.48 3.44 163.6 0.49 8.89 0.018 Lead Zinc Soot 0.41 40.75 1.72 3.68 31.93 0.31 421.3 0.90 3.81 0.17 Lead sulfate slag 0.06 64.5 2.13 0.11 / / 0.72 / 10.01 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com