Method for welding magnesium oxide target to back plate

A magnesium oxide and target technology, applied in welding equipment, welding/welding/cutting items, auxiliary devices, etc., can solve problems such as insufficient bonding force and unsatisfactory wettability, and achieve increased wettability, enhanced welding quality, and enhanced Effect of Weld Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

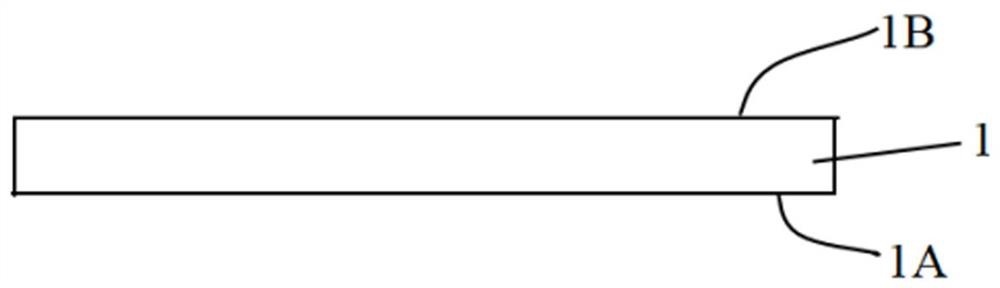

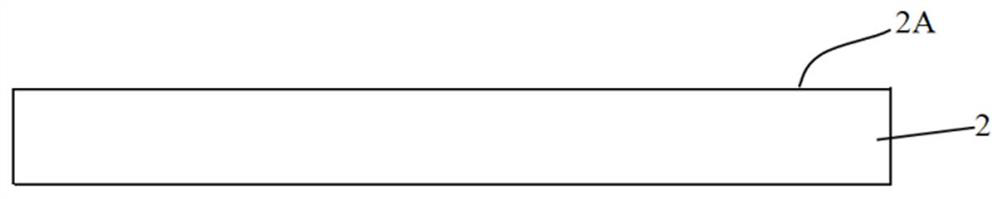

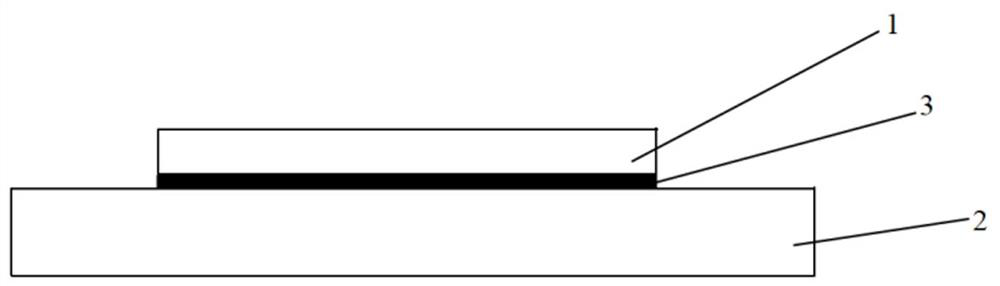

[0037] The steps of brazing a magnesia round target with a diameter of 200mm and a copper backplate are as follows:

[0038] Step 1: Wrap the sputtering surface of the target with high temperature resistant tape to prevent pollution;

[0039] Step 2: Polish the welding surface of the magnesium oxide target and the copper back plate with a steel rinse, then clean with isobutanol to remove oil and impurities, and then blow it off with an air gun;

[0040] Step 3: Select 200-mesh diamond sand grains for sandblasting, and the air pressure range in the sandblasting process is 0.3Mpa. After sand blasting, the welding surface is cleaned and dried with isobutanol again. After sand blasting, a rough layer with an average depth of 3-8 μm is formed on the welding surface of the magnesium oxide target and the back plate.

[0041] Step 4: Put the welding plane of the magnesium oxide target and the copper back plate upward on the heating platform, raise the temperature to 170°C at 4°C / min,...

Embodiment example 2

[0050] The steps of brazing a magnesia round target with a diameter of 300mm and an aluminum back plate are as follows:

[0051] Steps 1 to 3: Same as steps 1 to 3 of Implementation Case 1;

[0052] Step 4: Same as Step 4 of Implementation Case 1; where the heating rate is raised to 180°C at a rate of 3°C / min, and the temperature is kept constant;

[0053] Step 5: Same as Step 5 of Implementation Case 1; wherein the mass fraction of In in the solder is 98.6%, the mass fraction of Sn is 0.8%, and the mass fraction of Ga is 0.6%.

[0054] Step 6: Same as Step 6 of Implementation Case 1;

[0055] Step 7: Same as Step 7 of Implementation Case 1; wherein the heating system is:

[0056] a) Heating: heat at 5°C / min to 100°C for 30 minutes, heat at 3°C / min to 185°C for 60 minutes, and heat at 3°C / min to 210°C for 60 minutes;

[0057] b) Cool down: lower the temperature at 3°C / min to 135°C for 30 minutes, then air cool to room temperature.

[0058] Further, after scraping off excess ...

Embodiment example 3

[0061] The steps for brazing a magnesia rectangular target with a diameter of 300mm and a stainless steel back plate are as follows:

[0062] Steps 1 to 3: Same as steps 1 to 3 of Implementation Case 1;

[0063] Step 4: Same as Step 4 of Implementation Case 1; where the heating rate is raised to 180°C at a rate of 4°C / min, and the temperature is kept constant;

[0064] Step 5: Same as Step 5 of Implementation Case 1; wherein the mass fraction of In in the solder is 97.5%, the mass fraction of Sn is 1.5%, and the mass fraction of Ga is 1%.

[0065] Step 6: Same as Step 6 of Implementation Case 1;

[0066] Step 7: Same as Step 7 of Implementation Case 1; wherein the heating system is:

[0067] a) Heating: heat at 4°C / min to 100°C for 30 minutes, heat at 3°C / min to 180°C for 60 minutes, and heat at 3°C / min to 205°C for 60 minutes;

[0068] b) Cool down: reduce temperature at 3°C / min to 130°C for 30 minutes, then air cool to room temperature.

[0069] Further, after scraping o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average depth | aaaaa | aaaaa |

| Welding strength | aaaaa | aaaaa |

| Welding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com