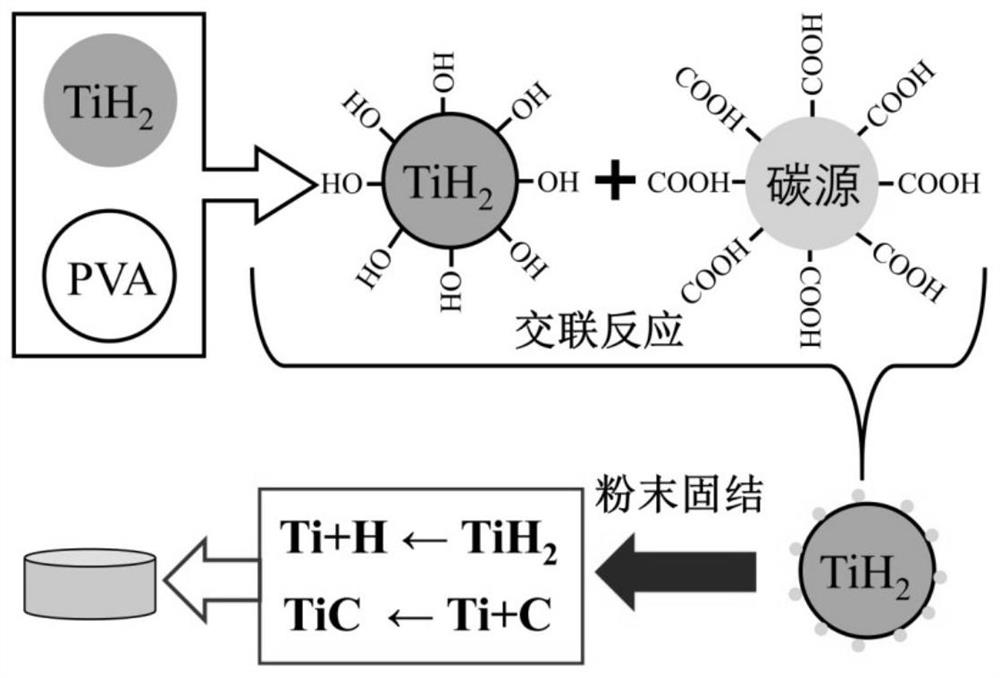

Method for preparing TiC reinforced titanium-based composite material based on cross-linking modified sintered titanium hydride

A titanium-based composite material, cross-linking modification technology, applied in the direction of transition element hydrides, etc., can solve the problems of high manufacturing cost, high residual porosity of titanium-based composite materials, poor mechanical properties, etc., to reduce the cost of alloy raw materials, Great practical and industrial value, fast and efficient preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

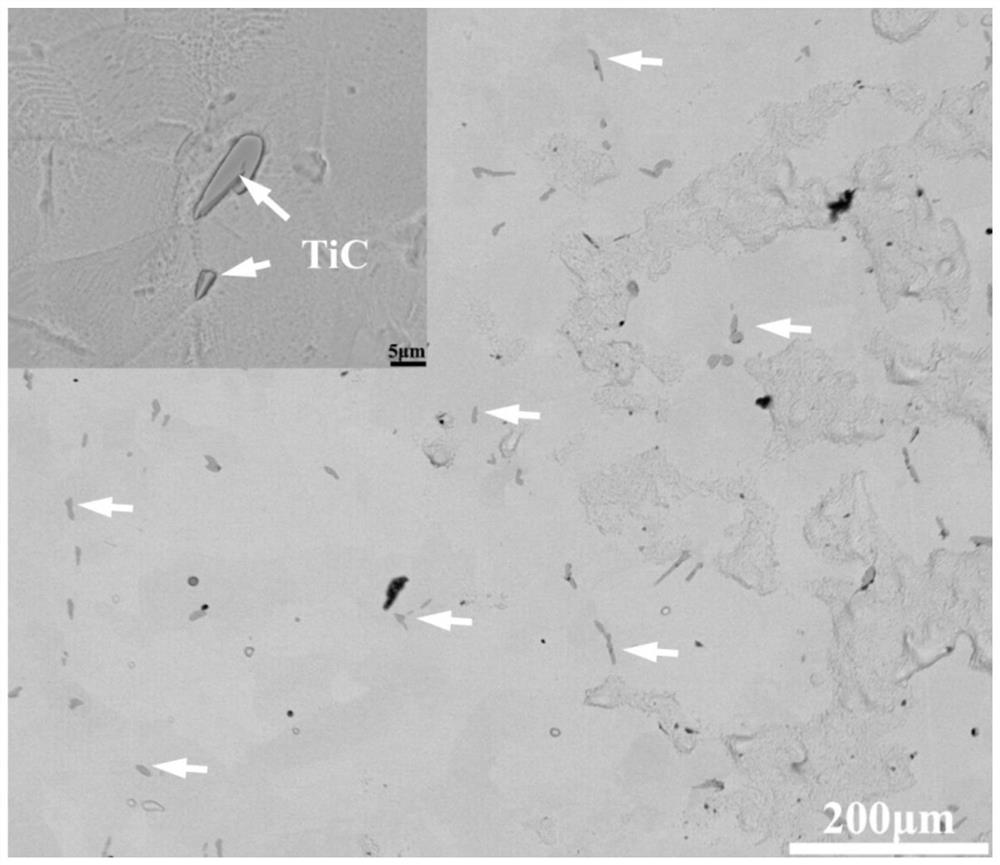

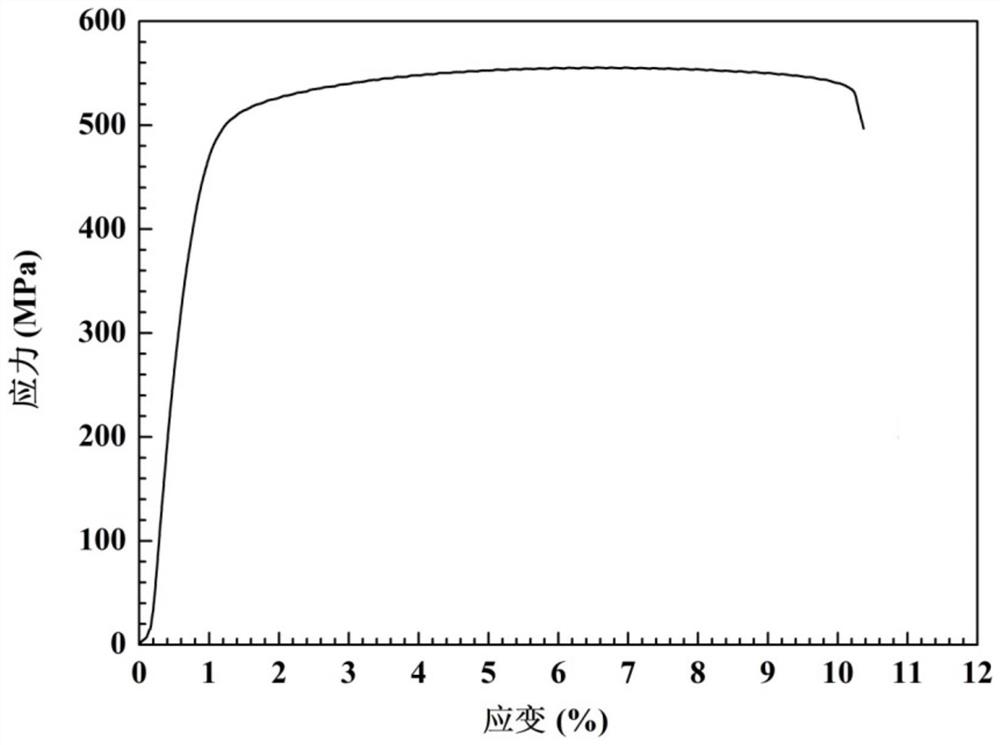

[0043] A method for preparing TiC-reinforced titanium-based composite material by sintering titanium hydride based on cross-linking reaction, comprising the following steps:

[0044] The raw materials used in this embodiment are as follows: polyvinyl alcohol (350), titanium hydride powder (100 mesh), deionized water, absolute ethanol, stearic acid.

[0045] (1) Surface hydroxylation of titanium hydride powder: First, weigh 10 parts by mass of polyvinyl alcohol powder and pour it into 200 parts by volume of deionized water, heat the solution to 87°C with a magnetic stirrer and stir for 2 hours at a speed of 1000rpm to make polyvinyl alcohol powder Vinyl alcohol was completely dissolved and cooled to room temperature; then, weighed 50 parts by mass of titanium hydride powder and slowly poured it into the polyvinyl alcohol solution at a speed of 1000rpm and stirred for 3 hours; finally, repeated the process of filtration and deionized water washing for 3 times and then heated at 7...

Embodiment 2

[0050] A method for preparing TiC-reinforced titanium-based composite material by sintering titanium hydride based on cross-linking reaction, comprising the following steps:

[0051] The raw materials used in this embodiment are as follows: polyvinyl alcohol (350), titanium hydride powder (100 mesh), deionized water, and graphene oxide.

[0052] (1) Surface hydroxylation of titanium hydride powder: First, weigh 1 mass part of polyvinyl alcohol powder and pour it into 200 volume parts of deionized water, heat the solution to 87°C with a magnetic stirrer and stir for 2 hours at a speed of 2000rpm to make polyethylene After the alcohol is completely dissolved, cool to room temperature; secondly, weigh 50 parts by mass of titanium hydride powder and slowly pour it into the polyvinyl alcohol solution and stir at a speed of 1000rpm for 3 hours; finally, repeat the process of filtering and deionized water washing for 3 times, Dry for 12 hours to obtain pretreated titanium hydride pow...

Embodiment 3

[0057] A method for preparing TiC-reinforced titanium-based composite material by sintering titanium hydride based on cross-linking reaction, comprising the following steps:

[0058] The raw materials used in this embodiment are as follows: polyvinyl alcohol (350), titanium hydride powder (100 mesh), deionized water, and graphene oxide.

[0059] (1) Surface hydroxylation of titanium hydride powder: First, weigh 20 parts by mass of polyvinyl alcohol powder and pour it into 200 parts by volume of deionized water, heat the solution to 87°C with a magnetic stirrer and stir for 2 hours at a speed of 1000rpm to make polyvinyl alcohol powder Vinyl alcohol was completely dissolved and cooled to room temperature; secondly, weighed 50 parts by mass of titanium hydride powder and slowly poured it into the polyvinyl alcohol solution and stirred at a speed of 1000 rpm for 3 h; finally, repeated the process of filtering and washing with deionized water for 3 times, at 70 The pretreated tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com