Preparation method of cobalt-nitrogen-doped carbon-coated nano cobalt phosphide electrocatalyst

A technology of carbon coating and catalyst, which is applied in the field of preparation of cobalt-nitrogen-doped carbon-coated nano-cobalt phosphide composite bifunctional electrocatalysts, achieving the effects of mild conditions, environmental friendliness and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

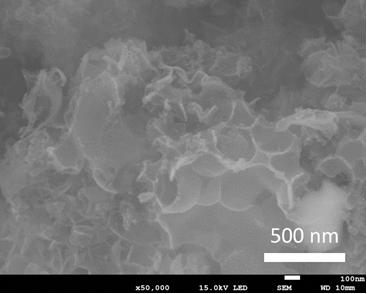

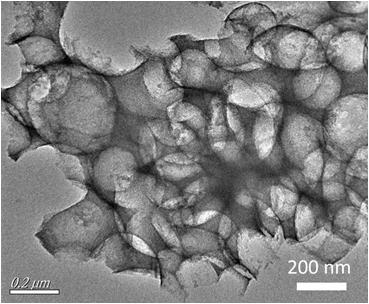

Image

Examples

Embodiment 1

[0032]Mix 1.75 grams of cobalt nitrate hexahydrate (about 6 millimoles of cobalt), 0.66 milliliters of 70 wt.% phytic acid (about 6 millimoles of phosphorus), and 20 milliliters of 5 wt.% polyvinyl alcohol 1788 (about 1 gram of carbon source) A transparent solution is formed; immerse the melamine foam with a size of 1.3×2×2 cubic centimeters into the above solution, and after the solution is saturated with adsorption, take it out and place it in a 60 degree blast drying oven to dry to obtain melamine containing cobalt, nitrogen, phosphorus and carbon Foam precursor;

[0033]Place the melamine foam precursor in a tube furnace, use 50 ml / min of high-purity nitrogen as a protective gas, heat it to 900 degrees at a heating rate of 5 degrees / minute, and keep it for 1 hour, and obtain an annealed product after cooling;

[0034]Grind the annealed product into a powder with a mortar, add 5 ml of 1 mol / L hydrochloric acid solution to ultrasonic for 1 hour, and then centrifuge with water and ethano...

Embodiment 2

[0042]Mix 1.43 grams of cobalt chloride hexahydrate (about 6 millimoles of cobalt), 1.32 milliliters of 70 wt.% phytic acid (about 12 millimoles of phosphorus), and 20 milliliters of 2 wt.% polyvinyl alcohol 1788 (about 0.4 grams of carbon source). Form a transparent solution; immerse the melamine foam with a size of 1×2×2 cubic centimeters into the above solution, and after the solution is saturated, take it out and place it in a 60 degree air blast drying oven to dry to obtain melamine containing cobalt, nitrogen, phosphorus and carbon Foam precursor;

[0043]Place the melamine foam precursor in a tube furnace, use 50ml / min of high-purity nitrogen as the protective gas, heat it to 800°C at a heating rate of 5°C / min, and keep it for 2 hours. After cooling, an annealed product is obtained;

[0044]Grind the annealed product into powder with a mortar, add 5 ml of 1 mol / L sulfuric acid solution and stir for 2 hours, and then wash with water and ethanol for 3 times. The resultant product is ...

Embodiment 3

[0047]Mix 1.75 grams of cobalt nitrate hexahydrate (about 6 millimoles of cobalt), 1.1 grams of triethyl phosphate (about 6 millimoles of phosphorus) and 20 milliliters of 5 wt.% polyvinyl alcohol 1788 (about 1 gram of carbon source) to form a transparent solution ; Immerse the melamine foam with a size of 1×2×2 cubic centimeters into the above solution. After the solution is saturated by adsorption, take it out and place it in a 60-degree blast drying oven to obtain a melamine foam precursor containing cobalt, nitrogen, phosphorus, and carbon. ;

[0048]Place the melamine foam precursor in a tube furnace, use 50ml / min of high-purity argon as the protective gas, heat it to 1000°C at a heating rate of 10°C / min, and keep it for 1 hour, and obtain an annealed product after cooling;

[0049]Grind the annealed product into a powder with a mortar, add 5 ml of 1 mol / L nitric acid solution to ultrasonic for 1 hour, and then centrifuge with water and ethanol for 3 times. The resultant product is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com