Panchromatic Micro/Nano LED array direct epitaxy method and structure

An array and epitaxy technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of difficulty in independent addressing of a single drive and complex technology, reduce manufacturing difficulty and manufacturing cost, overcome process bottlenecks, and achieve ultra-high performance. The effect of high LED density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below through specific embodiments.

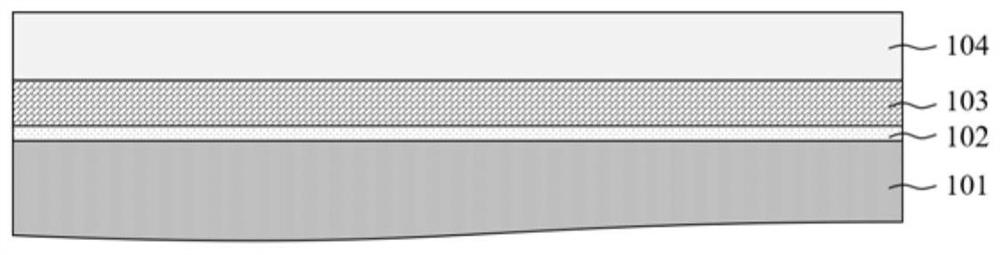

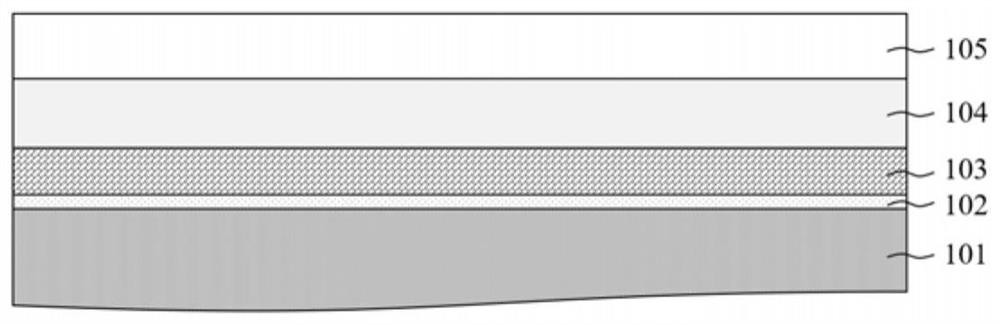

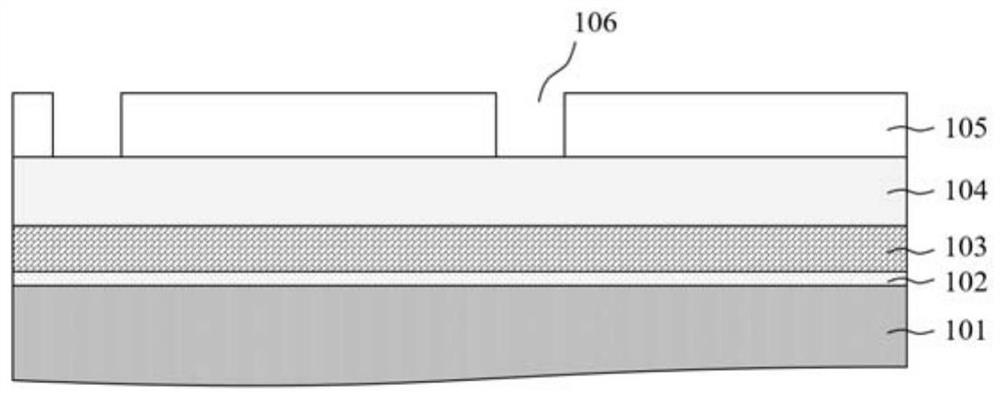

[0048] The present invention proposes a direct epitaxial structure of a full-color Micro / Nano LED array, including a bottom-up substrate 101, a buffer layer 102, an unintentionally doped layer 103, an n-type layer 104, and an array of LED light-emitting units. The LED light-emitting unit The array is a light-emitting unit of any color produced by a step-by-step selective area epitaxy method; it also includes an n-type electrode array and a p-type electrode array, the n-type electrode array is electrically connected to the n-type layer 104, and the p-type electrode array is connected to the light-emitting unit The p-type layer is electrically connected to realize independent addressing and driving. The structure of the present invention can realize the independent addressing and driving of each LED.

[0049] The present invention also proposes a direct epitaxial method of Micro / Nano fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com