Automatic polishing platform and polishing method thereof

A platform and automatic technology, applied in the direction of grinding machine, grinding frame, grinding bed, etc., can solve the problems of low grinding efficiency, poor grinding effect, inability to meet, etc., to improve grinding efficiency and improve grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

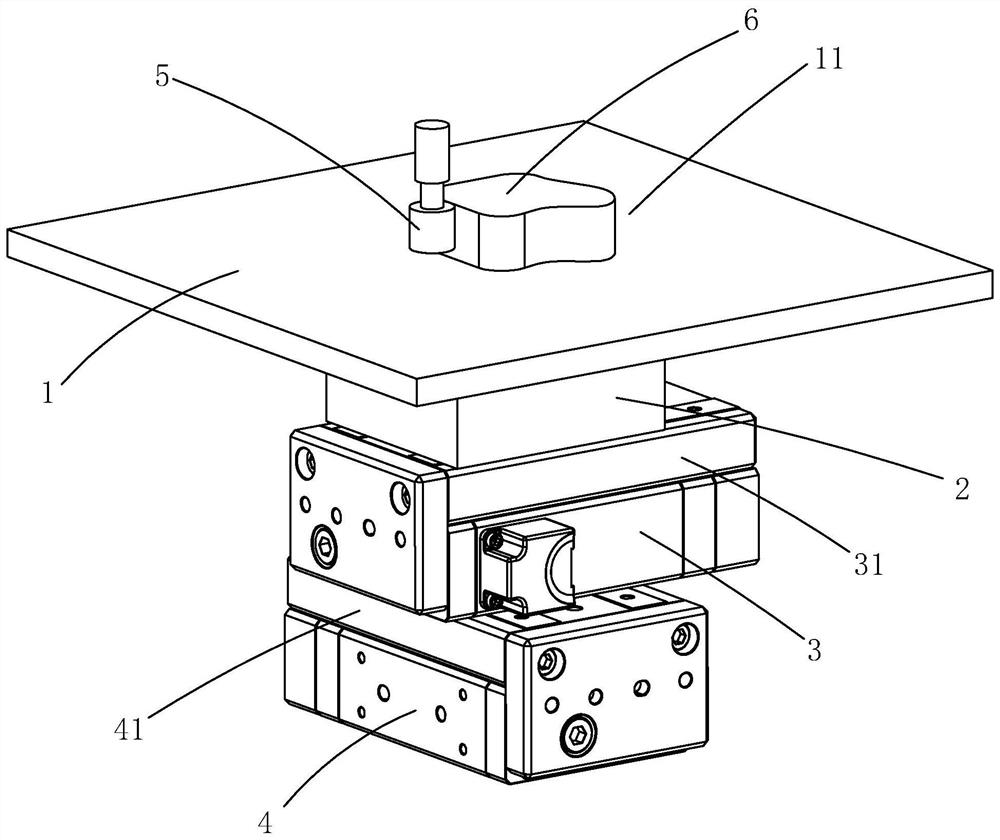

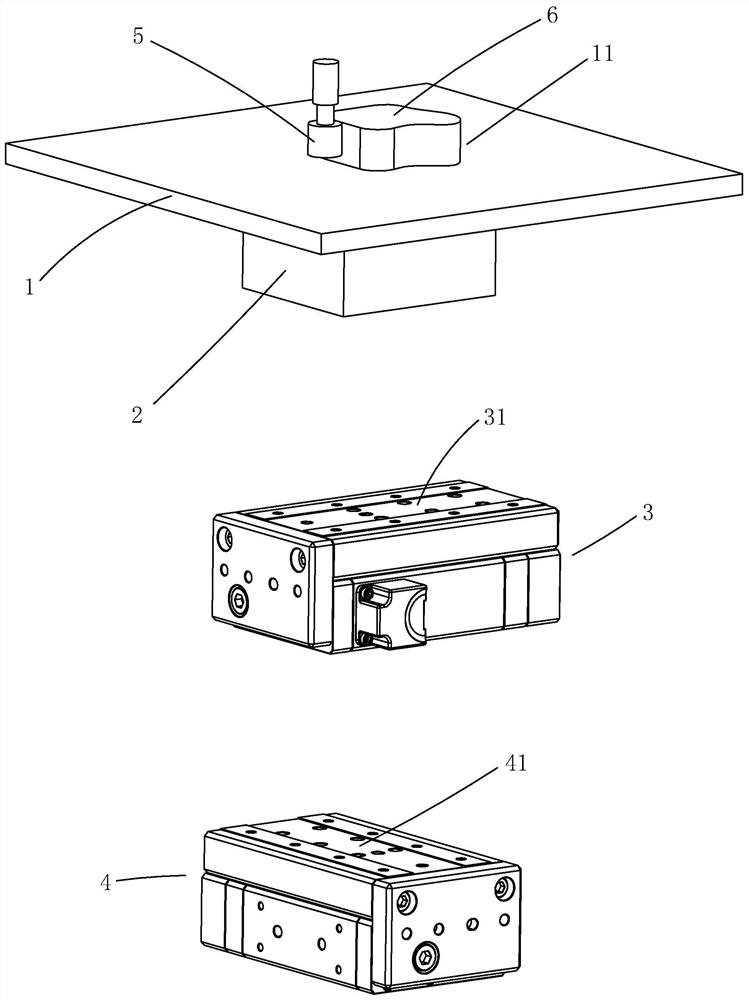

[0032] Example, combined with Figure 1 to Figure 2 As shown, an automatic grinding platform includes a mechanical arm (not shown in the figure), a grinding head assembly (not shown in the figure), a platform 1, a two-dimensional force sensor 2, a longitudinal push rod device 3, a transverse push rod device 4 and A controller (not shown in the figure), the mechanical arm is connected to the grinding head assembly, and the mechanical arm has a built-in processor for executing preset grinding trajectory commands. The grinding head assembly includes a grinding head 5 and a driving device, and the driving device drives The grinding head 5 rotates, and the platform 1 is provided with a workpiece placement area 11 , and the grinding head 5 is close to the workpiece placement area 11 .

[0033] The horizontal push rod device 4 includes a screw rod (not shown in the figure), a nut (not shown in the figure), a servo motor (not shown in the figure), a push rod (not shown in the figure),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com